High-entropy polyurethane and preparation method thereof

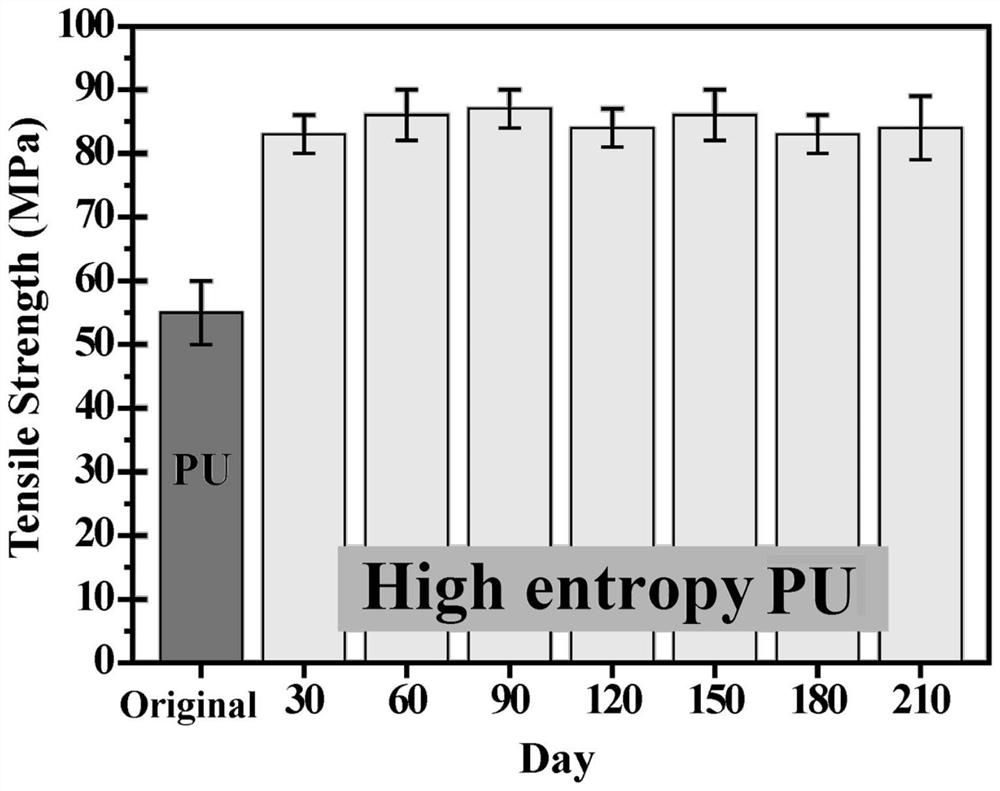

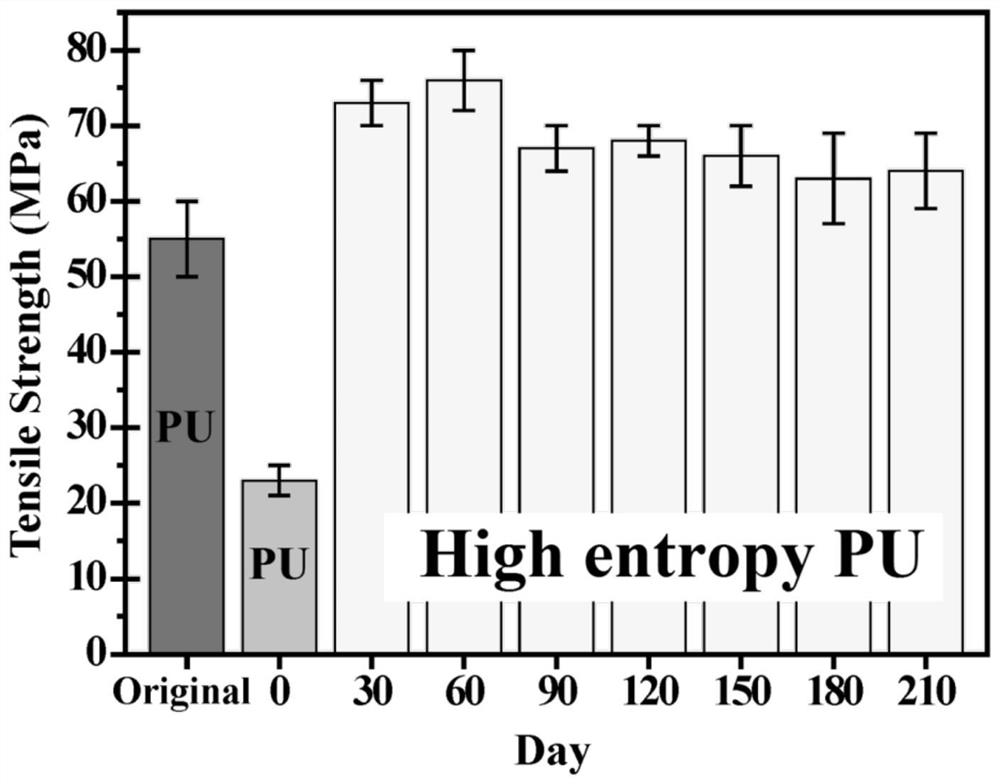

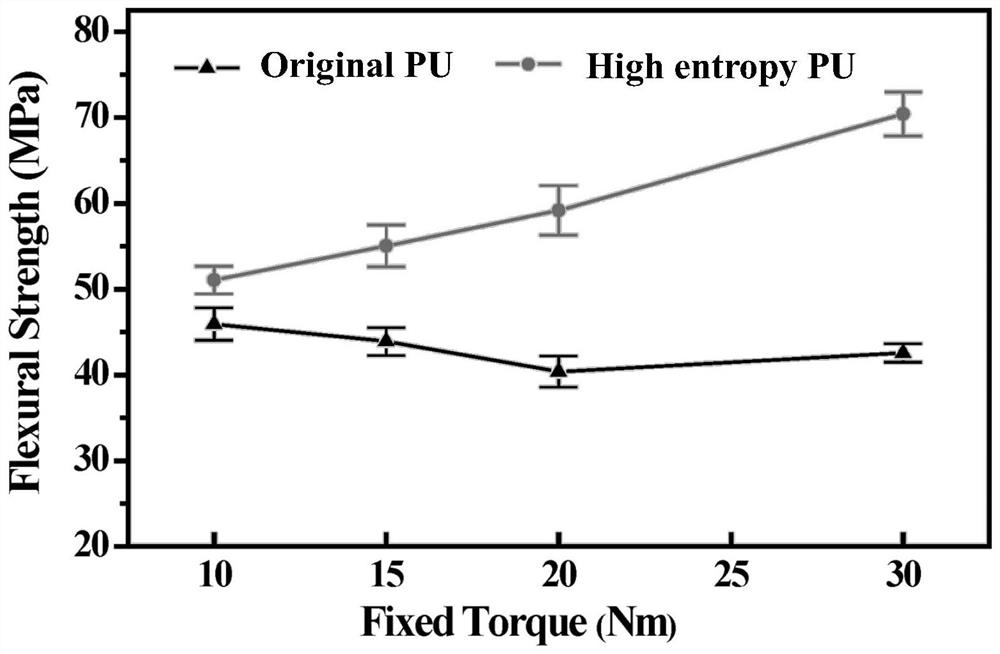

A polyurethane and polyurethane prepolymer technology, applied in the field of polymer materials, can solve the problems of low tear resistance and tensile strength, poor low temperature resistance of ordinary polyurethane, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a high-entropy polyurethane, which is prepared by reacting a polyurethane prepolymer with a chain extender. The raw materials for preparing the polyurethane prepolymer include the following components in weight percentage: polyester polyol 50.0%, diisocyanate 35.0%, plasticizer 15.0%, among which, polyester polyol is polyester diol PE4020 with a number average molecular weight of 3000, prepared from adipic acid and 1,4-butanediol, diisocyanate Including 4,4'-diphenylphenylmethane diisocyanate 30% and carbodiimide modified MDI (liquefied MDI) 5%, plasticizer is butyl benzyl phthalate (BBP), chain extender The agent is 1,4-butanediol.

[0033] The preparation method of this high entropy polyurethane comprises the following steps:

[0034] (1) React polyester polyol, diisocyanate and plasticizer at a temperature of 80° C. for 2 hours, remove air bubbles under vacuum to obtain a polyurethane prepolymer with an isocyanate content of 5.6%; wherein, d...

Embodiment 2

[0037] This embodiment provides a high-entropy polyurethane, which is prepared by reacting a polyurethane prepolymer with a chain extender. The raw materials for preparing the polyurethane prepolymer include the following components in weight percentage: polyester polyol 63.0%, 32.0% diisocyanate, 5.0% plasticizer, wherein the polyester polyol is polyester diol PE2420 with a number average molecular weight of 3200, prepared from adipic acid, ethylene glycol, and 1,4-butanediol into, wherein the mass ratio of ethylene glycol and 1,4-butanediol is 3:1, diisocyanates include 4,4'-diphenylphenylmethane diisocyanate 28% and carbodiimide modified MDI (liquefied MDI) 5%, the plasticizer is dimethoxyethyl phthalate (DMEP), and the chain extender is a mixture of 1,4-butanediol and trimethylolpropane with a mass ratio of 5:1.

[0038] The preparation method of this high entropy polyurethane comprises the following steps:

[0039] (1) React polyester polyol, diisocyanate and plasticizer...

Embodiment 3

[0042] This embodiment provides a high-entropy polyurethane, which is prepared by reacting a polyurethane prepolymer with a chain extender. The raw materials for preparing the polyurethane prepolymer include the following components in weight percentage: polyester polyol 38%, 37% diisocyanate, 25.0% plasticizer, among which, polyester polyol is polyester diol PE 2420 with a number average molecular weight of 3000, prepared from adipic acid, ethylene glycol, and 1,4-butanediol Formed, wherein the mass ratio of ethylene glycol and 1,4-butanediol is 3:1, the diisocyanate includes 4,4'-diphenylphenylmethane diisocyanate 32% and carbodiimide modified MDI ( Liquefied MDI) 5%, the plasticizer is 9-88SG, and the chain extender is a mixture of 1,4-butanediol and trimethylolpropane with a mass ratio of 20:3.

[0043] The preparation method of this high entropy polyurethane comprises the following steps:

[0044] (1) React polyester polyol, diisocyanate and plasticizer at a temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com