Asphalt modifier and its preparation process

An asphalt modifier and modification technology, which is applied in the field of asphalt, can solve the problems of poor aging resistance, poor temperature stability of asphalt pavement, and poor dispersion of modifiers, so as to improve the anti-oxidative aging performance of asphalt and improve the anti-oxidative aging of asphalt Performance, the effect of excellent high and low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

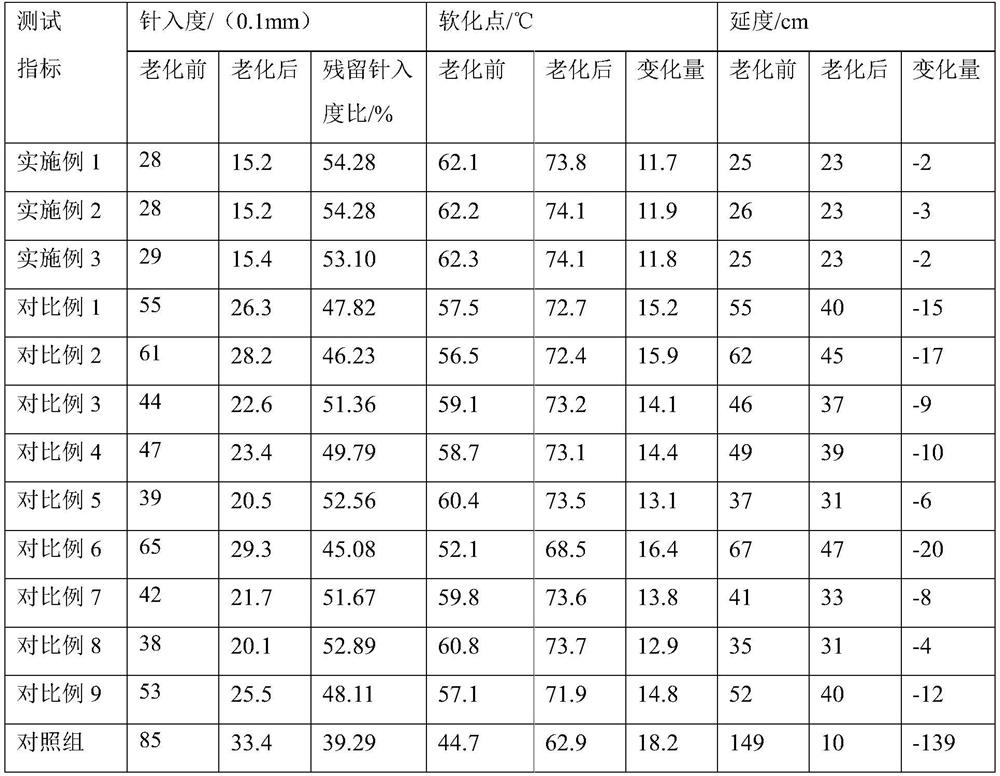

Examples

Embodiment 1

[0027] The invention provides an asphalt modifier, comprising the following raw materials in parts by weight: 20 parts of graphene, 10 parts of carbon nanotubes, 4 parts of dopamine, 15 parts of vegetable oil polyols, 30 parts of polytetrafluoroethylene fiber and 1 part stabilizer.

[0028] Wherein, the stabilizer is sulfur.

[0029] The graphene has been pretreated, specifically:

[0030] S1, disperse the graphene in the ethanol solution, control the mass concentration of the graphene to 0.3 mg / mL, and obtain a colloidal solution after ultrasonic treatment for 2 hours;

[0031] S2, add surfactant in colloidal solution, stir colloidal solution under the stirring velocity of 1000r / min and carry out foaming 40min, obtain foam suspension, wherein the weight ratio of the add-on of surfactant and graphene in colloidal solution is 0.03 :1;

[0032] S3. Freeze-drying and pulverizing the foam suspension to obtain pretreated graphene.

[0033] The surfactant in step S2 is sodium do...

Embodiment 2

[0040] The invention provides an asphalt modifier, comprising the following raw materials in parts by weight: 30 parts of graphene, 15 parts of carbon nanotubes, 8 parts of dopamine, 25 parts of vegetable oil polyols, 40 parts of polytetrafluoroethylene fiber and 3 parts stabilizer.

[0041] Wherein, the stabilizer is sulfur.

[0042] The graphene has been pretreated, specifically:

[0043] S1, disperse graphene in ethanol solution, control the mass concentration of graphene to be 0.7mg / mL, after ultrasonic treatment for 2.5h, obtain colloidal solution;

[0044]S2, add surfactant in colloidal solution, stir colloidal solution under the stirring speed of 1500r / min and carry out foaming 60min, obtain foam suspension, wherein the weight ratio of the add-on of surfactant and graphene in colloidal solution is 0.1 :1;

[0045] S3. Freeze-drying and pulverizing the foam suspension to obtain pretreated graphene.

[0046] The surfactant in step S2 is sodium dodecylsulfonate.

[00...

Embodiment 3

[0053] The invention provides an asphalt modifier, comprising the following raw materials in parts by weight: 25 parts of graphene, 13 parts of carbon nanotubes, 6 parts of dopamine, 20 parts of vegetable oil polyols, and 35 parts of polytetrafluoroethylene fiber and 2 parts stabilizer.

[0054] Wherein, the stabilizer is sulfur.

[0055] The graphene has been pretreated, specifically:

[0056] S1, disperse the graphene in the ethanol solution, control the mass concentration of the graphene to 0.5 mg / mL, and obtain a colloidal solution after ultrasonic treatment for 2.3 hours;

[0057] S2, add surfactant in colloidal solution, stir colloidal solution under the stirring speed of 1300r / min and carry out foaming 50min, obtain foam suspension, wherein the weight ratio of the add-on of surfactant and graphene in colloidal solution is 0.07 :1;

[0058] S3. Freeze-drying and pulverizing the foam suspension to obtain pretreated graphene.

[0059] The surfactant in step S2 is sodiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com