Double-amplitude four-cable-plane multi-tower cable-stayed bridge with annular row support stump flowerpot-shaped bracket

A technology for supporting tree stumps and cable-stayed bridges, which is applied in the direction of cable-stayed bridges, erection/assembly bridges, bridges, etc., and can solve the difficulties in the construction of cantilever X-shaped brackets, the increased force on bridge towers, and the addition of cable towers and foundations scale and other issues, to achieve the effect of enhancing the effect of three-dimensional compression restraint, improving structural rigidity, and reducing mid-span deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

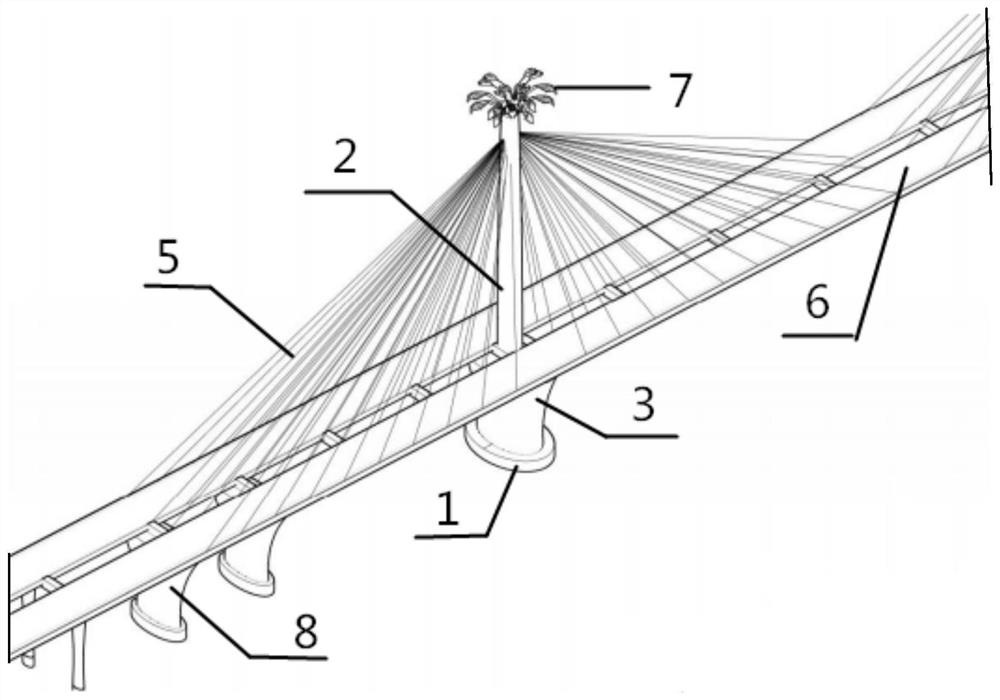

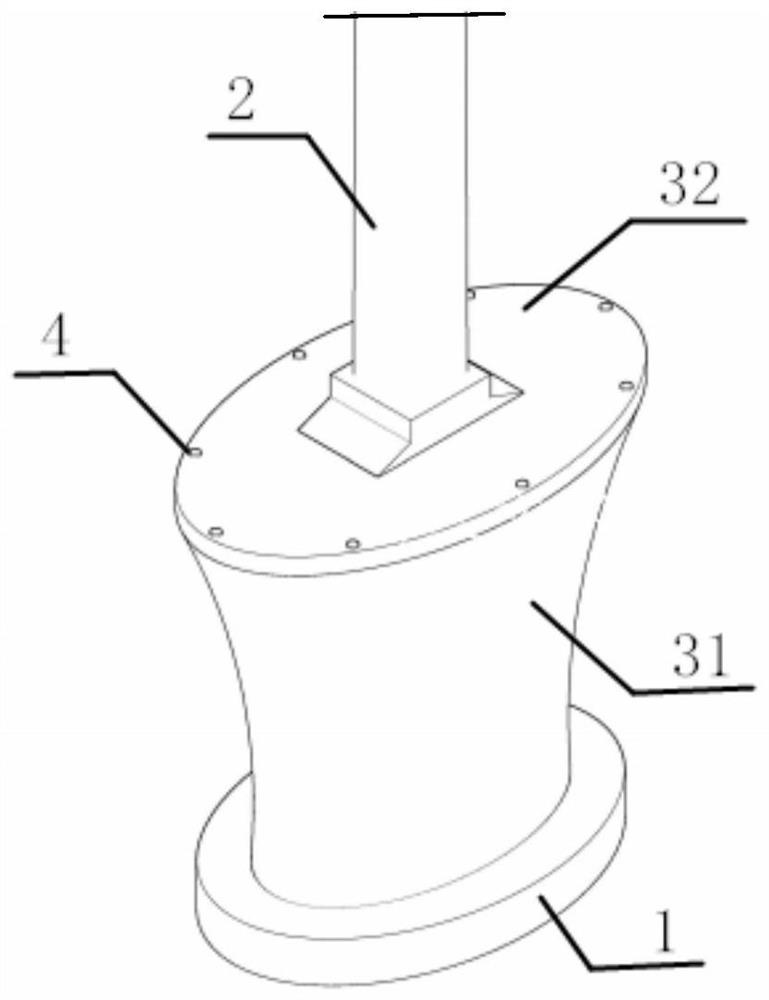

[0054] A double-width four-cable surface multi-tower cable-stayed bridge with tree stump flowerpot-shaped brackets of ring-row supports of the present invention, comprising bridge tower foundation 1, variable cross-section prestressed steel pipe concrete hollow column bridge tower 2, tree stump flowerpot-shaped brackets Frame 3, ring-arranged support 4, double-width main girder deck 5, cable-stayed cables 6 and artificial leaf tower crown 7, characterized in that: variable cross-section prestressed steel pipe concrete hollow column bridge tower 2 is set on the bridge tower foundation 1 , the tree stump flowerpot-shaped bracket 3 rests on the bridge tower foundation 1, the tree stump flowerpot-shaped bracket 3 wraps the variable-section prestressed steel pipe concrete hollow column bridge tower 2, and the top of the tree stump flowerpot-shaped bracket 3 is arranged in a circular arrangement The support 4, the double-width main girder bridge deck 5 rest on the stump flowerpot-sha...

Embodiment 2

[0058] A construction method for a double-width four-cable surface multi-tower cable-stayed bridge with tree stump flowerpot-shaped brackets ring-row support, characterized in that it includes the following steps:

[0059] Step 1: Carry out the bridge site selection of the double-width four-cable plane multi-tower cable-stayed bridge, drive the man-made pile foundation, carry out the construction of the bridge tower foundation 1, carry out the construction of the approach bridge, and carry out the construction of the single-leaf hyperboloid side pier 8;

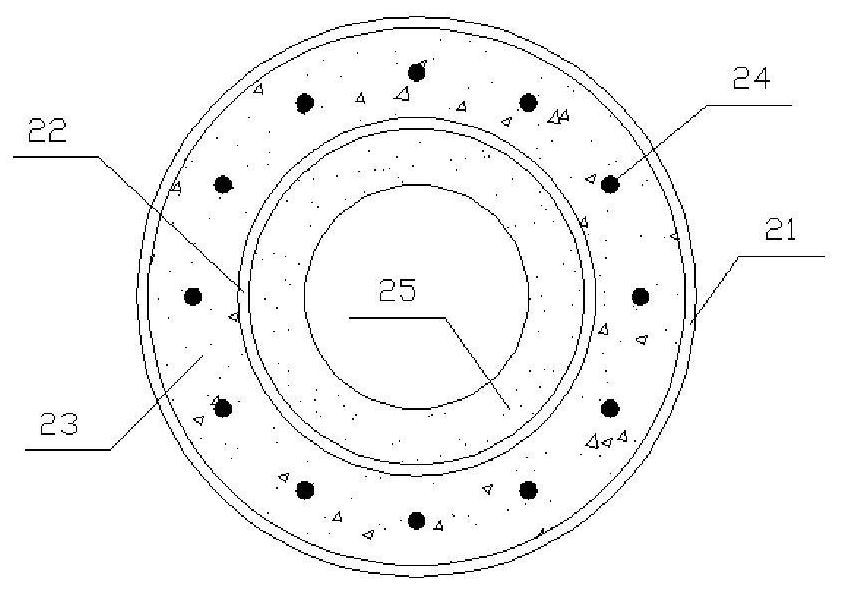

[0060] Step 2: On the bridge tower foundation 1, install variable-section outer steel pipes 21 and inner steel pipes 22, arrange unbonded prestressed steel bars 24 in the pipes, pour concrete 23 in the pipes, install perforated diaphragms 25, and form variable cross-sections Prestressed steel tube concrete hollow column bridge tower 2;

[0061] Step 3: Before the initial setting of the concrete 23 in the pipe, stretch a small...

Embodiment 3

[0068] For a Strait Bridge, the span of the main bridge is 200+3×400+200 meters, a double-width, four-cable plane, three-tower cable-stayed bridge, and the approach bridge is a continuous beam of 5×60 meters. The main bridge adopts a double-width four-cable plane multi-tower cable-stayed bridge structure with ring-row supports, tree stumps, and flowerpot-shaped brackets. The total span of the bridge deck is 60 meters, and the width of the left and right steel box girders is 24 meters. The net distance between the left and right steel box girders is 12 meters. Four-cable-plane cable-stayed cables obliquely suspend the double-width main girder deck. The distance between the cables is 20 meters. A 3-meter-wide steel box girder is installed every 60 meters to connect the left and right steel box girder deck girders.

[0069] The bridge tower foundation cap of this bridge is elliptical. On the bridge tower foundation, a variable cross-section prestressed steel pipe concrete hollow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com