Post-treatment exhaust system pipe fitting welding protection structure

A technology for welding and protecting the structure of pipe fittings, applied in welding equipment, welding equipment, welding accessories, etc., can solve the problems of welding penetration, blackening, uneven gas protection, etc., to avoid blackening at the weld, improve sealing, The effect of avoiding adverse risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

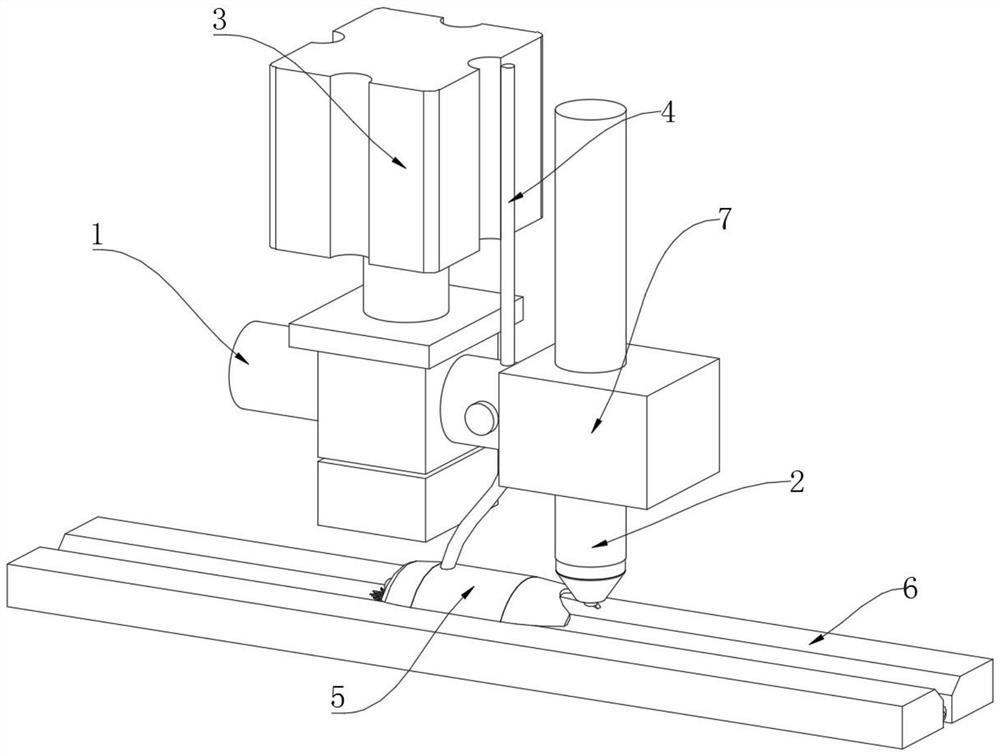

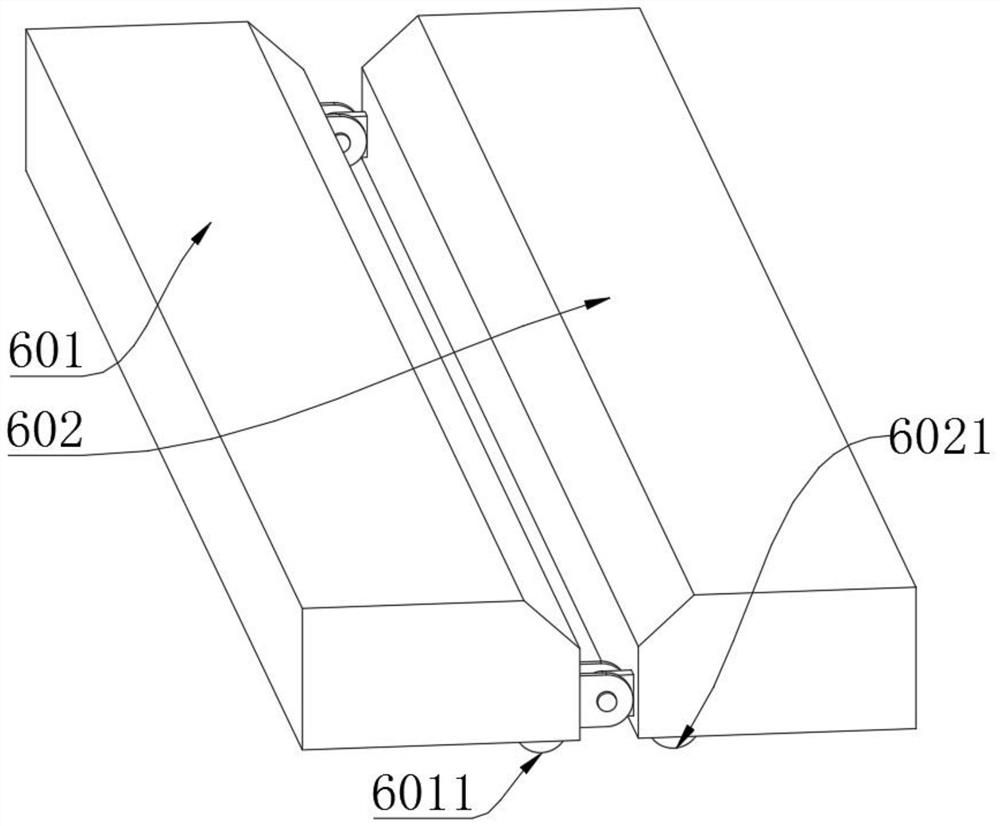

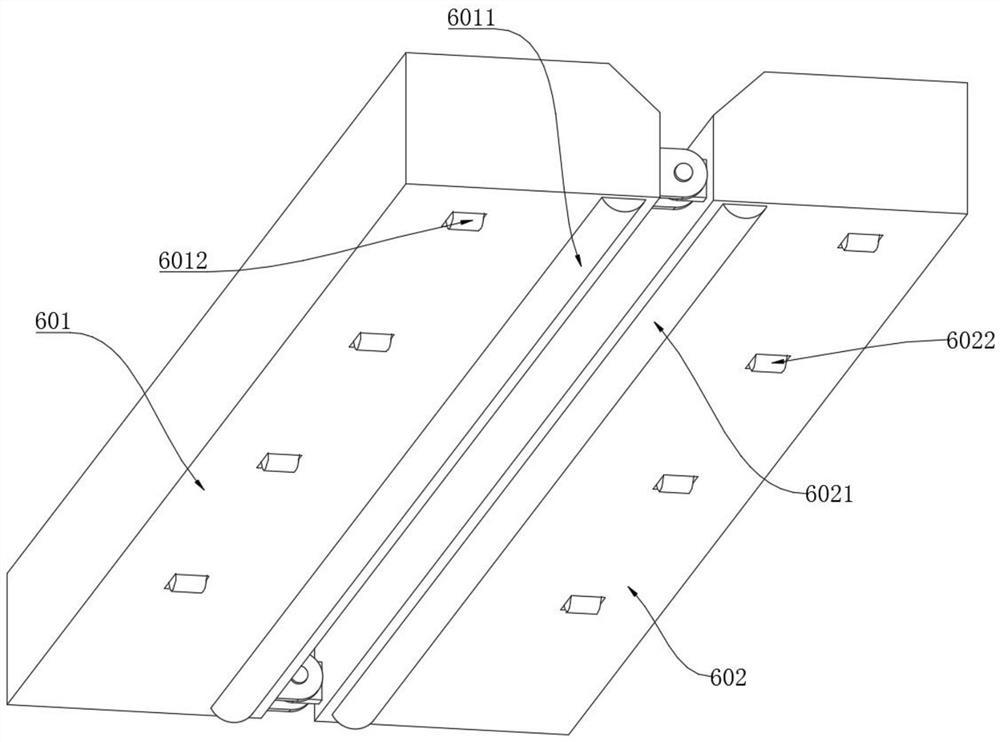

[0026] as attached figure 1 to attach Figure 5 Shown:

[0027] The invention provides a post-processing exhaust system pipe fitting welding protection structure, comprising an adjusting bracket 1, a delivery cylinder 3, a high temperature resistant spacer 5, a fixing plate 6, and a gas collecting device 8; the adjusting bracket 1 is movably connected with a welding torch bracket 2, And the welding torch bracket 2 is fixedly connected with a welding torch 7 by bolts; the end of the piston rod of the delivery cylinder 3 is fixedly connected with the frame body of the adjustment bracket 1; the high temperature resistant spacer 5 is fixedly connected with the lower end of the argon delivery pipe 4; It is connected to the left end of the high temperature-resistant septum 5 by welding; the fixed plate 6 includes a front pressure plate 601 and a rear pressure plate 602, and the rear surface of the front pressure plate 601 is movably connected with the rear pressure plate 602 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com