Preparation method of cellulose nano-fibril aerogel suitable for layer-by-layer self-assembly process

A layer-by-layer self-assembly and nanofibril technology, applied in the field of aerogels, can solve the problems of reduced utilization, easy agglomeration, and inability to achieve nano-level scale control, and achieves high wet strength, high surface charge, good The effect of shape stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

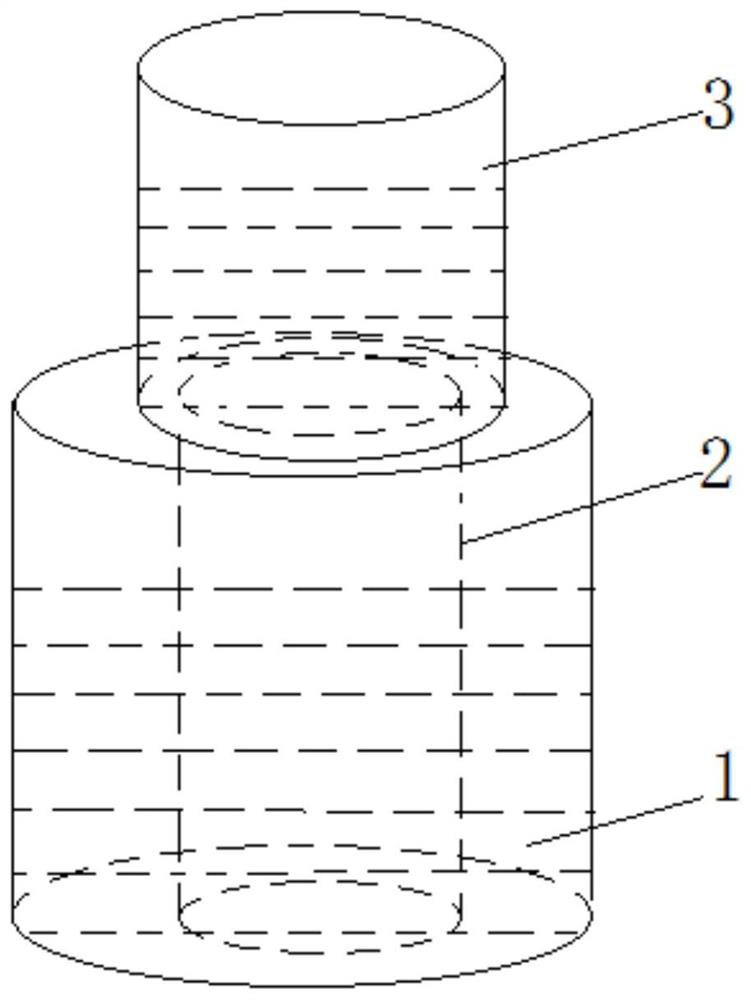

[0019] The preparation method of the cellulose nanofibril airgel applicable to the layer-by-layer self-assembly process of the present invention, the steps are as follows:

[0020] 1. Ultrasonic dispersion of cellulose nanofibrils (CNF) produced by TEMPO oxidation into water to obtain a 1wt% cellulose nanofibril dispersion;

[0021] 2. Dilute polyethyleneimine (PEI) aqueous solution with a molecular weight of 70000 to 15%;

[0022] 3. Mix the cellulose nanofibril dispersion obtained in step 1) with the polyethyleneimine aqueous solution obtained in step 2) at a mass ratio of 1:2 to 2:1, disperse it evenly, and let stand to obtain the structure Stable CNF hydrogel;

[0023] 4. Pre-freeze the CNF hydrogel obtained in step 3), and then freeze-dry to obtain the CNF aerogel suitable for the LBL process.

[0024] In order to better understand the steps of the above preparation method, it is described in detail.

Embodiment 1

[0026] A method for preparing a cellulose nanofibril aerogel suitable for a layer-by-layer self-assembly process, comprising the following steps:

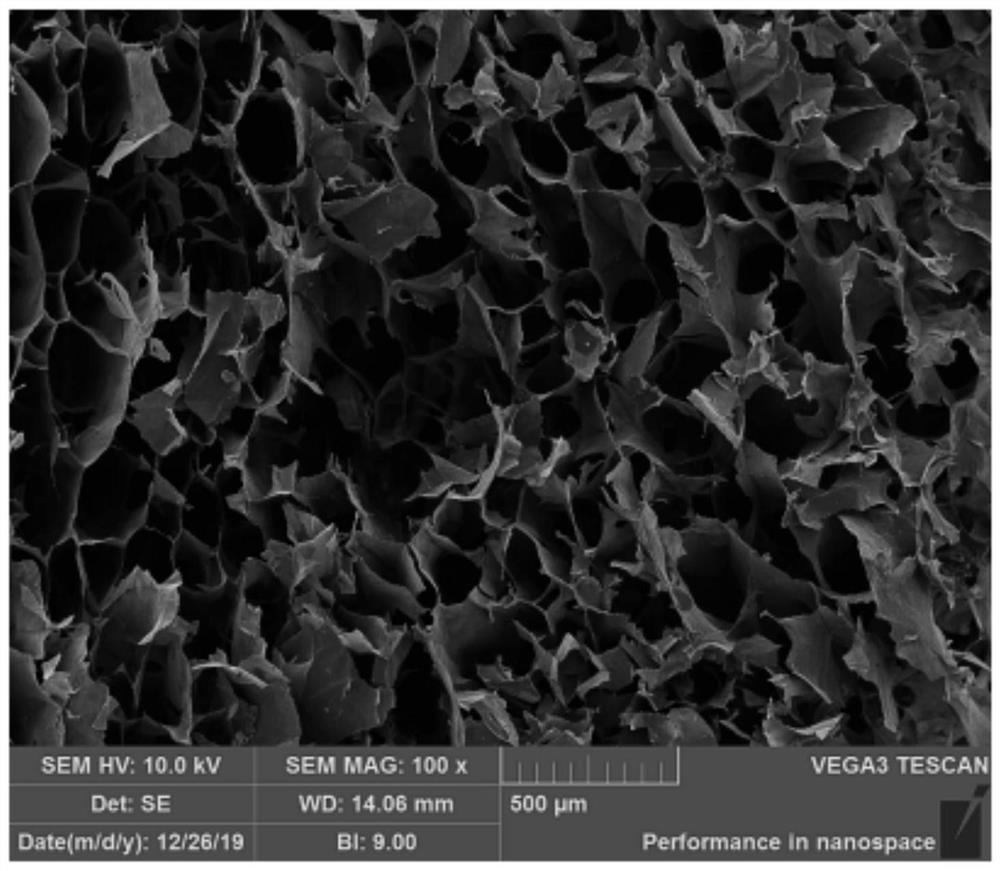

[0027] 1) Ultrasonic dispersion of cellulose nanofibrils (CNF) prepared by TEMPO oxidation into water to obtain a 1 wt% cellulose nanofibril dispersion. Among them, the cellulose nanofibrils (CNF) prepared by the TEMPO oxidation method were purchased from Tianjin Wood Spirit Technology Co., Ltd. The obtained nanocellulose has a diameter of 5-20 nm and a length of 1-5 μm.

[0028] 2) Dilute polyethyleneimine (PEI) aqueous solution with a molecular weight of 70000 and a concentration of 50% to 15% with deionized water.

[0029] 3) Control the mass ratio of CNF dispersion liquid to PEI aqueous solution to be 1:1. Specifically: after mixing 30 mL of the cellulose nanofibril dispersion (CNF dispersion) obtained in step 1) with 2 g of a polyethyleneimine aqueous solution with a concentration of 15% obtained in step 2), stir rapidly wit...

Embodiment 2

[0034] A method for preparing a cellulose nanofibril aerogel suitable for a layer-by-layer self-assembly process, comprising the following steps:

[0035] 1) Ultrasonic dispersion of cellulose nanofibrils (CNF) prepared by TEMPO oxidation into water to obtain a 1 wt% cellulose nanofibril dispersion. Among them, the cellulose nanofibrils (CNF) prepared by the TEMPO oxidation method were purchased from Tianjin Wood Spirit Technology Co., Ltd. The obtained nanocellulose has a diameter of 5-20 nm and a length of 1-5 μm.

[0036] 2) Dilute polyethyleneimine (PEI) aqueous solution with a molecular weight of 70000 and a concentration of 50% to 15% with deionized water.

[0037] 3) Control the mass ratio of CNF dispersion liquid to PEI aqueous solution to be 1:2. Mix 30mL of the 1wt% cellulose nanofibril dispersion obtained in step 1) with 4g of a 15% polyethyleneimine aqueous solution, stir rapidly with a magnetic stirrer for 2 hours to disperse evenly, and then let it stand for mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com