Method for determining single crystal graphene orientation

A single crystal graphene and graphene technology, applied in the field of graphene, can solve the problems of high difficulty in sample preparation, complex analysis process, and high difficulty in preparation, and achieve the effects of convenient sample preparation, promotion of application, and reduction of preparation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] S1. Put the copper foil into the CVD quartz chamber, and use a vacuum pump to keep the chamber at a low pressure (specifically 1 Pa). The temperature of the chamber was raised to 1035° C. at 10° C. / min, during which argon gas flow (200 sccm flow rate) was maintained. After rising to 1035°C, introduce methane and hydrogen (the volume ratio of methane:hydrogen is 1:500, and the pressure in the chamber is kept at 2000Pa). After 0.2 hours of reaction, the growth is complete, the chamber is rapidly cooled to room temperature, hydrogen and methane are turned off, and the single crystal graphene-copper foil sample is taken out.

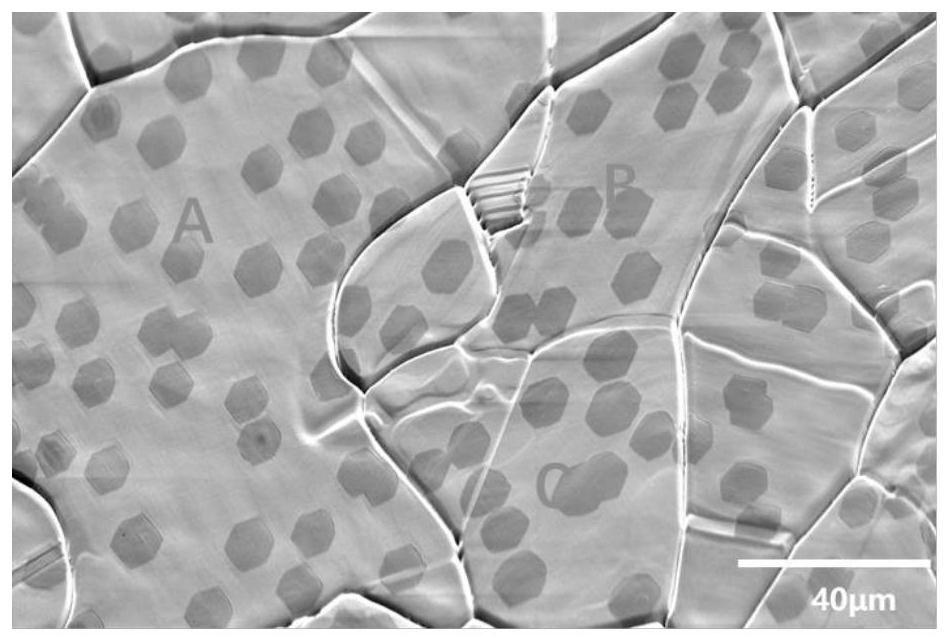

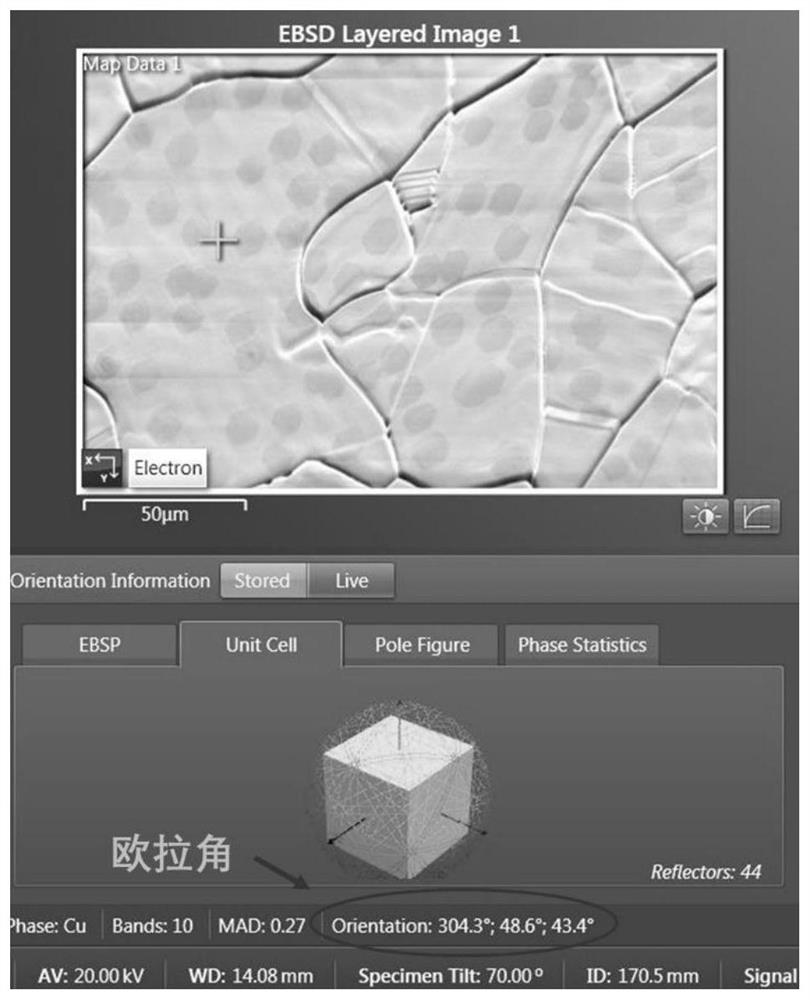

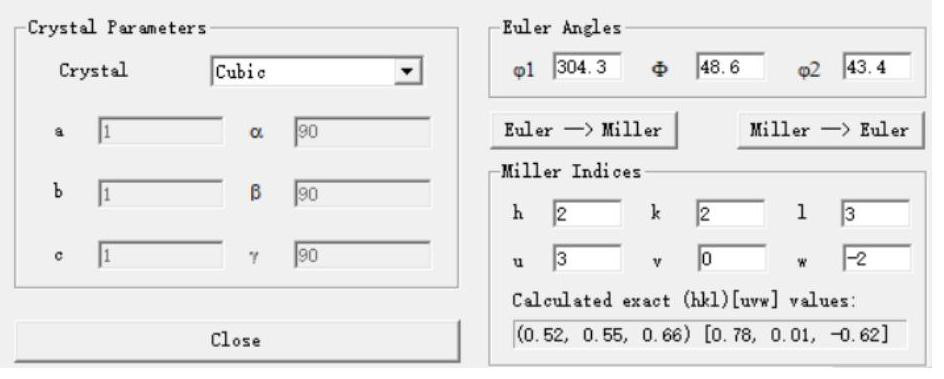

[0068] S2. Put the obtained single-crystal graphene-copper foil sample into a scanning electron microscope with an EBSD probe to obtain the crystal plane orientation information of the copper foil; meanwhile, obtain the graphene topography. Such as figure 1 shown.

[0069] S3, through the graphene topography, measure the angle θ between the edge of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com