Preparation process of gapless laminated film capacitor

A film capacitor and preparation technology, applied in the direction of film/thick film capacitors, laminated capacitors, fixed capacitor electrodes, etc., can solve the problems of affecting the high frequency characteristics of capacitance and affecting energy storage density, etc., and achieve high dielectric constant and large Effect of equivalent electrode surface area and reduction of equivalent inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The working principle and implementation method of the present invention will be further described in detail below in conjunction with the accompanying drawings.

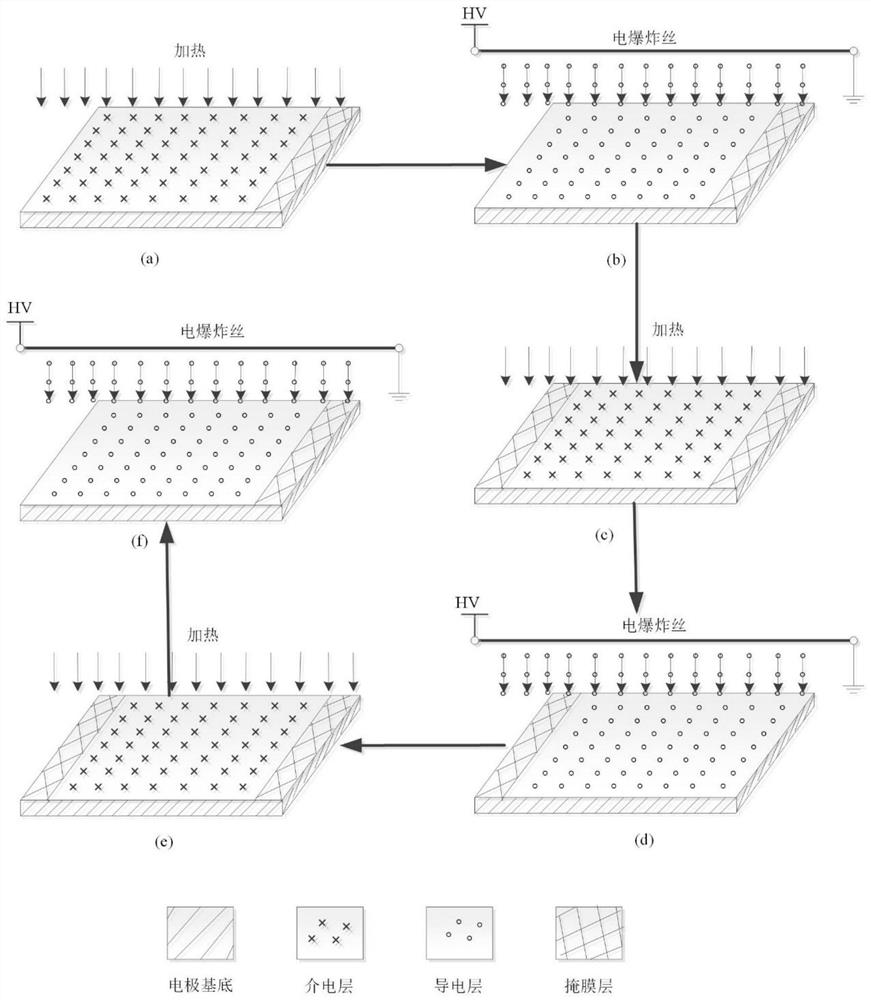

[0019] Such as figure 1 As shown, (a) is to prepare a dielectric layer on the electrode base material, (b) is to use the electric explosive wire method to prepare the first layer of conductive layer on the surface of the dielectric layer, (c) is to prepare a dielectric layer on the surface of the conductive layer , (d) is to adopt the electric explosive wire method to prepare the second layer of conductive layer on the surface of the dielectric layer, (e) is to prepare the dielectric layer on the surface of the conductive layer, (f) is to adopt the electric explosive wire method to prepare on the surface of the dielectric layer The third conductive layer.

[0020] figure 1 The preparation process of the stacked structure is shown, in which the mask layer at the edge of the material is to prevent the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com