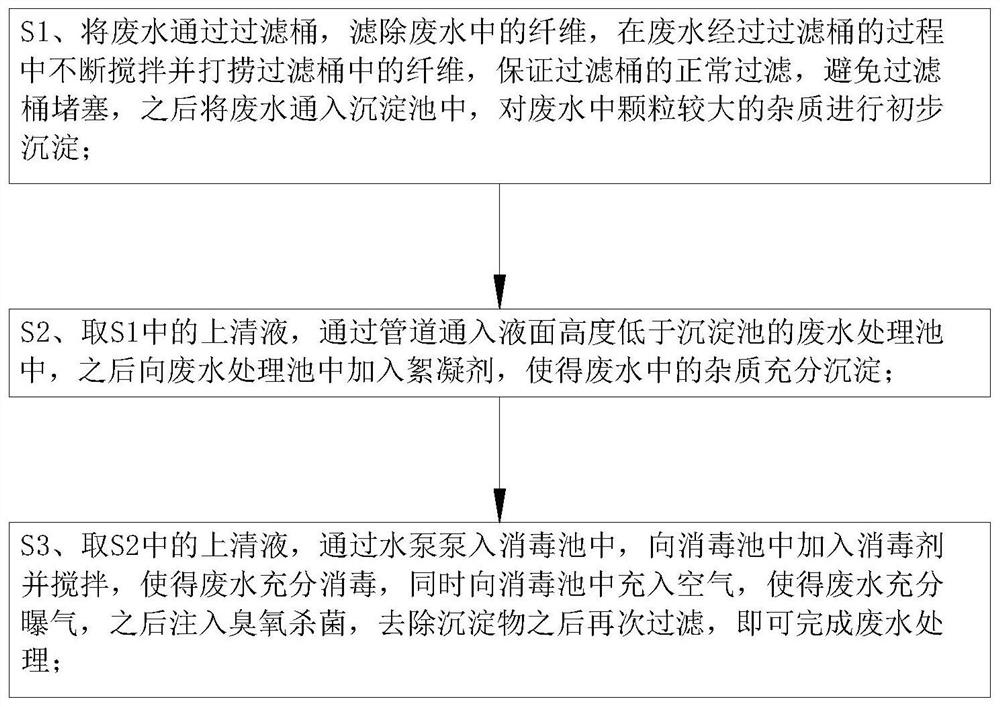

Papermaking wastewater treatment process

A technology for treating process and papermaking wastewater, which is applied in the direction of processing wastewater treatment, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve the problems of long interruption, low dredging efficiency, and affecting wastewater treatment efficiency, etc. Achieve the effects of increasing suction efficiency, increasing cleaning efficiency, and ensuring water pressure balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

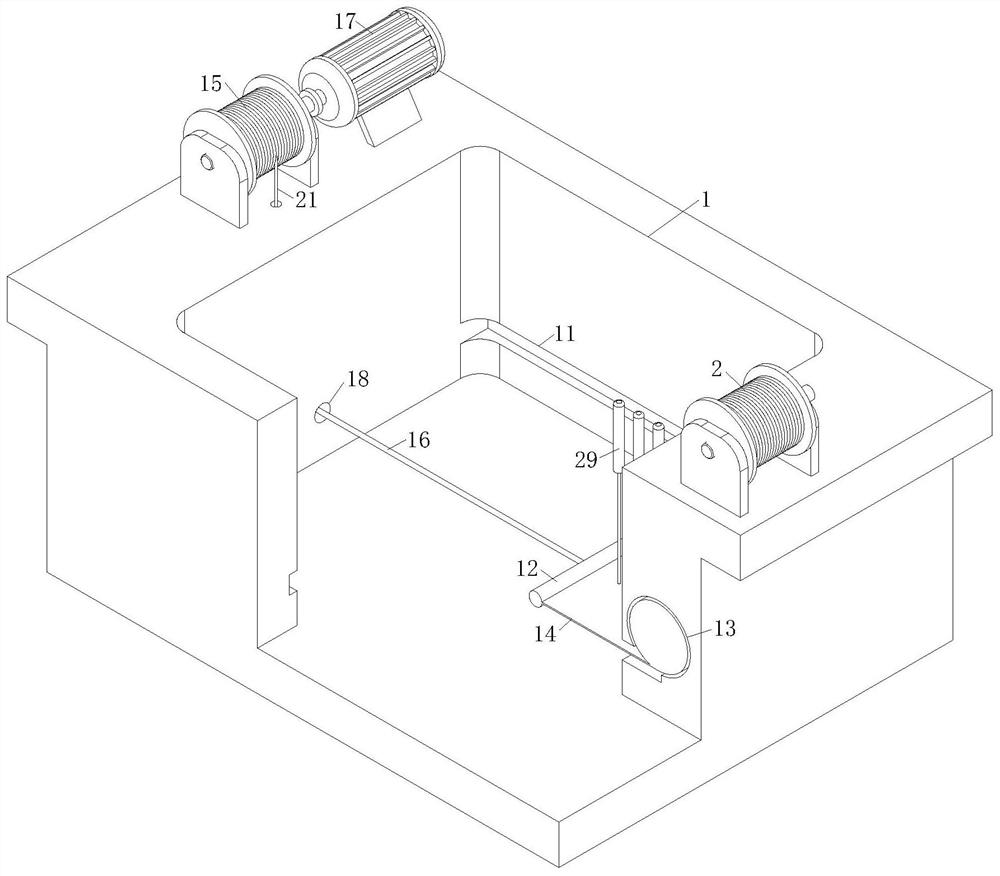

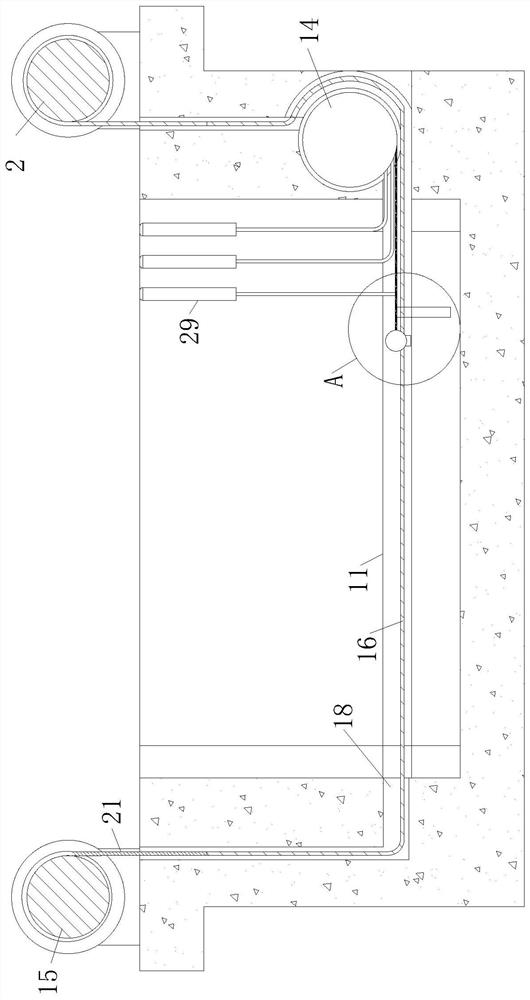

Embodiment approach

[0033] As an embodiment of the present invention, the top of the pool body 1 is provided with an unwinding roller 2 at a position corresponding to the storage chamber 13, and the end of the steel rope 16 close to the sliding rod 12 is wrapped around the roller blind 14 and then wound around the outer circumference of the unwinding roller 2. Rewinding the steel rope 16 by the unwinding roller 2 drives the rolling curtain 14 to be retracted, increasing the cleaning efficiency of the pool body 1. The rotation of the unwinding roller 2 drives the steel rope 16 to move closer to the storage chamber 13, because the steel rope 16 After bypassing the coiled roller blind 14, it is wound on the unwinding roller 2. The friction force between the steel rope 16 and the roller blind 14 drives the roller blind 14 to wind up quickly, which increases the resetting efficiency of the roller blind 14 and further reduces the cleaning of silt Time, to ensure that the tank body 1 returns to the best s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com