Method for obtaining angstrom-level smooth surface of yttrium oxide transparent ceramic

A transparent ceramic and smooth surface technology, which is applied in the direction of optical surface grinders, grinding/polishing equipment, polishing compositions containing abrasives, etc., can solve the problems of high cost, complicated equipment, low efficiency, etc., and achieve good expected results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

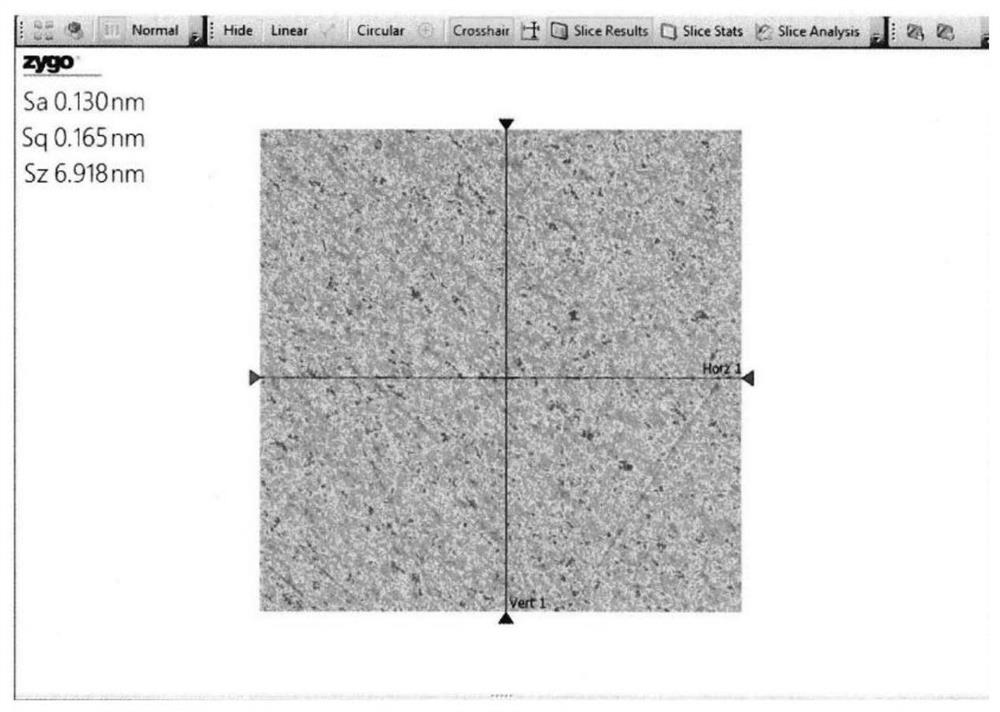

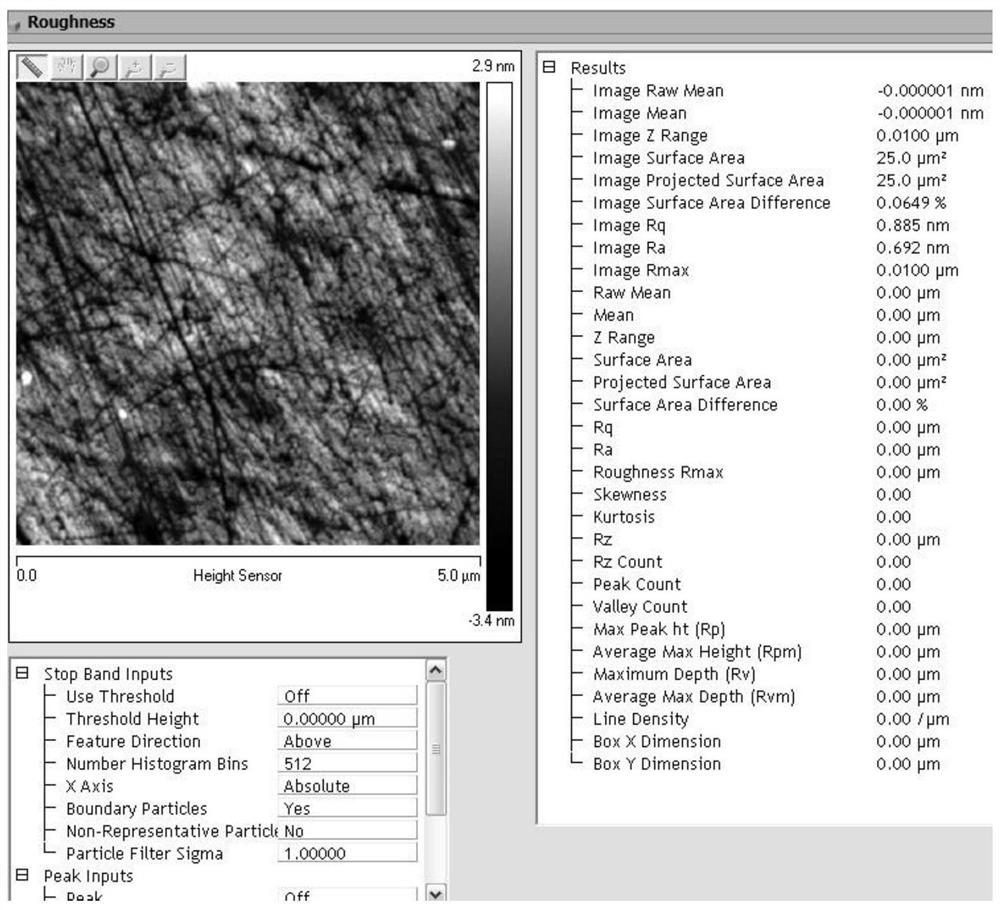

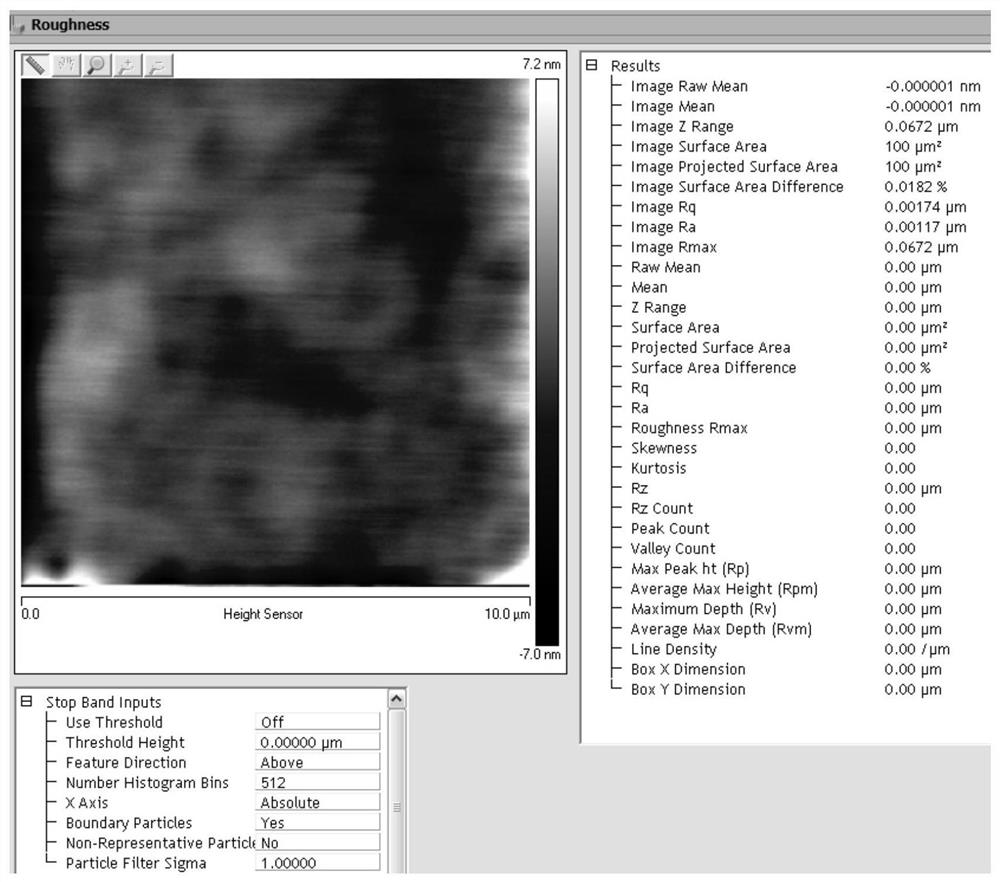

[0024] The present invention provides a method for obtaining angstrom-level smooth surface of yttrium oxide transparent ceramics. Taking the processing of yttrium oxide transparent ceramics with a diameter of 60mm and a thickness of 10mm as an example, the smoothness is required to meet the national standard I level, and the specific steps of the aperture 0.5N are:

[0025] (1) Preparation of coarse throwing liquid: Pour 500ml of deionized water into a beaker, weigh 30 grams of 0.5 micron chromium oxide micropowder and pour it into the beaker, stir to obtain a solution containing zirconia micropowder, adjust the pH value with hydrofluoric acid 5.4-5.8; chromium oxide powder has moderate hardness (Mohs hardness 6.5-7), good adhesion, can not only improve the removal efficiency but will not cause deep damage layer on the surface of yttrium oxide transparent ceramic devices; The surface is corrosive, which can better remove the sub-surface damage layer during the polishing process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com