Plastic toughening agent, reinforced and toughened polypropylene plastic and preparation method of reinforced and toughened polypropylene plastic

A technology of plastic toughening agent and polypropylene plastic, which is applied in the field of plastic toughening agent, reinforced and toughened polypropylene plastic and its preparation, can solve the problems of unsatisfactory toughening effect, reduced plastic performance, large addition amount, etc. Good toughening effect, improving impact resistance and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of plastic toughening agent, described plastic toughening agent is prepared by following method: under nitrogen atmosphere, dimethyl azobisisobutyrate and benzene are mixed, described dimethyl azobisisobutyrate and The mass ratio of benzene is 0.5:50, then add ethylene-butyl acrylate-glycidyl methacrylate, acrylonitrile and 2-ethylhexyl acrylate, the ethylene-butyl acrylate-glycidyl methacrylate , the mass ratio of acrylonitrile and 2-ethylhexyl acrylate is 0.5:65:35, and the mass ratio of described ethylene-butyl acrylate-glycidyl methacrylate and dimethyl azobisisobutyrate is 1:1; then add the benzene solution of 2-mercaptoethanol at a rate of 0.5mL / min, react at 62°C for 2.5h, and the rotation speed is 300rpm, the benzene solution of 2-mercaptoethanol and dimethyl azobisisobutyrate The mass ratio of the ester is 50.5:0.5, and the benzene solution of 2-mercaptoethanol is a mixture of 2-mercaptoethanol and benzene in a mass ratio of 0.5:50; then heat up to 73°C ...

Embodiment 2

[0042] A kind of plastic toughening agent, described plastic toughening agent is prepared by following method: under nitrogen atmosphere, dimethyl azobisisobutyrate and benzene are mixed, described dimethyl azobisisobutyrate and The mass ratio of benzene is 0.5:50, then add ethylene-butyl acrylate-glycidyl methacrylate, acrylamide and 2-ethylhexyl acrylate, the ethylene-butyl acrylate-glycidyl methacrylate , the mass ratio of acrylamide and 2-ethylhexyl acrylate is 0.5:65:35, and the mass ratio of described ethylene-butyl acrylate-glycidyl methacrylate and dimethyl azobisisobutyrate is 1:1; then add the benzene solution of 2-mercaptoethanol at a rate of 0.5mL / min, react at 62°C for 2.5h, and the rotation speed is 300rpm, the benzene solution of 2-mercaptoethanol and dimethyl azobisisobutyrate The mass ratio of the ester is 50.5:0.5, and the benzene solution of 2-mercaptoethanol is a mixture of 2-mercaptoethanol and benzene in a mass ratio of 0.5:50; then heat up to 73°C for 3 ...

Embodiment 3

[0046] A kind of plastic toughening agent, described plastic toughening agent is prepared by following method: under nitrogen atmosphere, dimethyl azobisisobutyrate and benzene are mixed, described dimethyl azobisisobutyrate and The mass ratio of benzene is 0.5:50, then add ethylene-butyl acrylate-glycidyl methacrylate, acrylamide and lauryl acrylate, the ethylene-butyl acrylate-glycidyl methacrylate, acrylamide and acrylic acid The mass ratio of lauryl ester is 0.5:65:35, and the mass ratio of described ethylene-butyl acrylate-glycidyl methacrylate and dimethyl azobisisobutyrate is 1:1; Then at 0.5mL / min Add the benzene solution of 2-mercaptoethanol at a high rate, react at 62°C for 2.5h, and the rotation speed is 300rpm. The mass ratio of the benzene solution of 2-mercaptoethanol to dimethyl azobisisobutyrate is 50.5:0.5, so The benzene solution of 2-mercaptoethanol is a mixture of 2-mercaptoethanol and benzene in a mass ratio of 0.5:50; then heat up to 73°C for 3 hours, and...

PUM

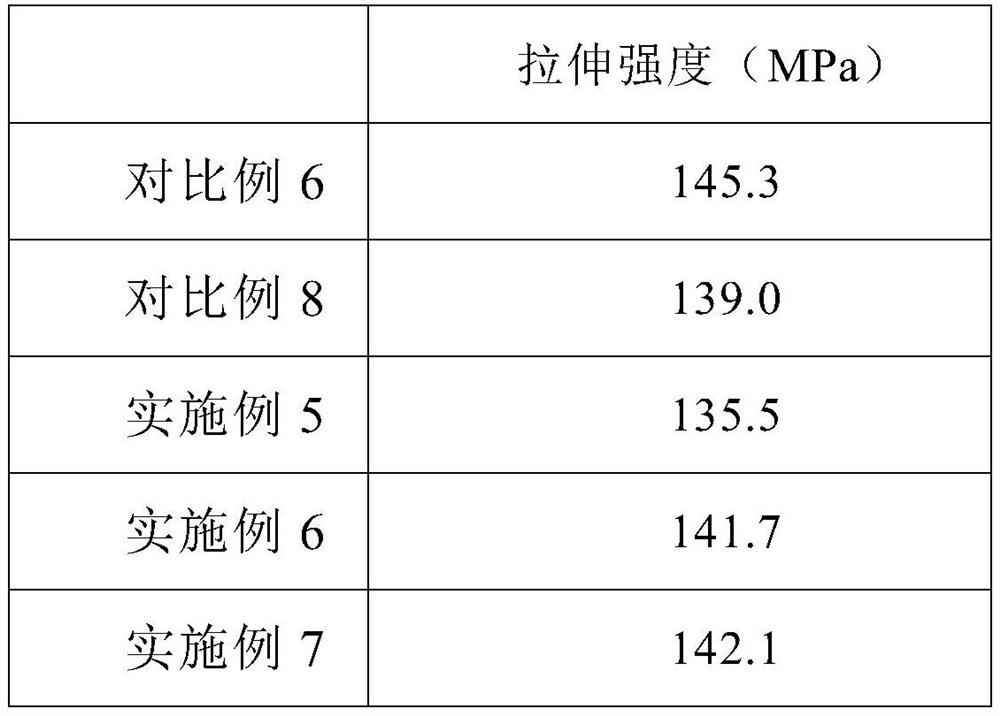

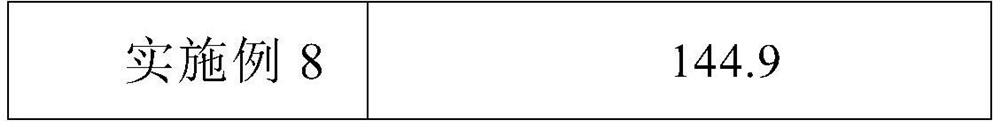

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com