Manufacturing process of two-dimensional material filled copper-clad plate

A two-dimensional material and manufacturing process technology, which is applied in the fields of printed circuit manufacturing, printed circuit precursor manufacturing, printed circuit secondary processing, etc., can solve problems such as high dielectric loss and inability to meet high-frequency circuit performance requirements, and achieve dielectric The effect of stable electrical properties, low dielectric loss, and low dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

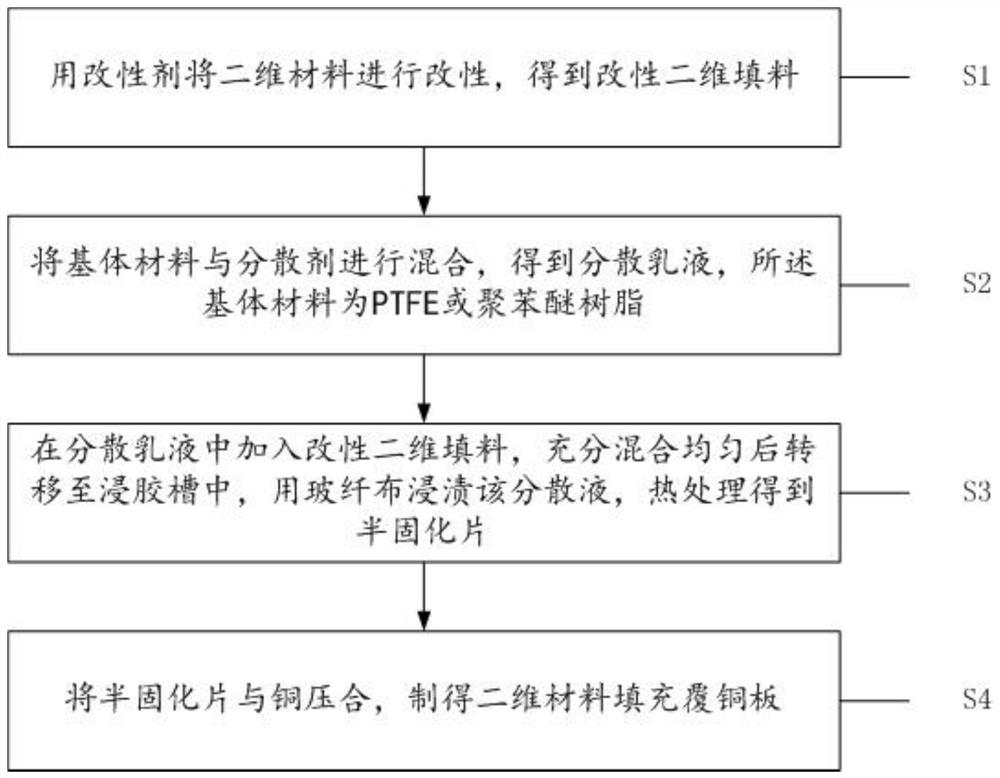

[0044] Please refer to figure 1 and figure 2 , Embodiment 1 of the present invention is: a manufacturing process for filling copper clad laminates with two-dimensional materials, including the following steps: S1, mixing two-dimensional materials with modifiers to obtain modified mixed solutions, which are filtered, cleaned and Dry to obtain the modified two-dimensional filler; S2, mix the matrix material with the dispersant to obtain a dispersed emulsion, the matrix material is PTFE or polyphenylene ether resin; S3, add the modified filler to the dispersed emulsion, fully After mixing evenly, transfer it to the dipping tank. In this embodiment, the dispersed emulsion is mixed with the modified two-dimensional filler to obtain a dispersion liquid, and the glass fiber cloth is impregnated with the dispersion liquid, and heat-treated to obtain a prepreg; S4. combined to prepare a two-dimensional material filled copper clad laminate. In other feasible embodiments, the matrix m...

Embodiment 2

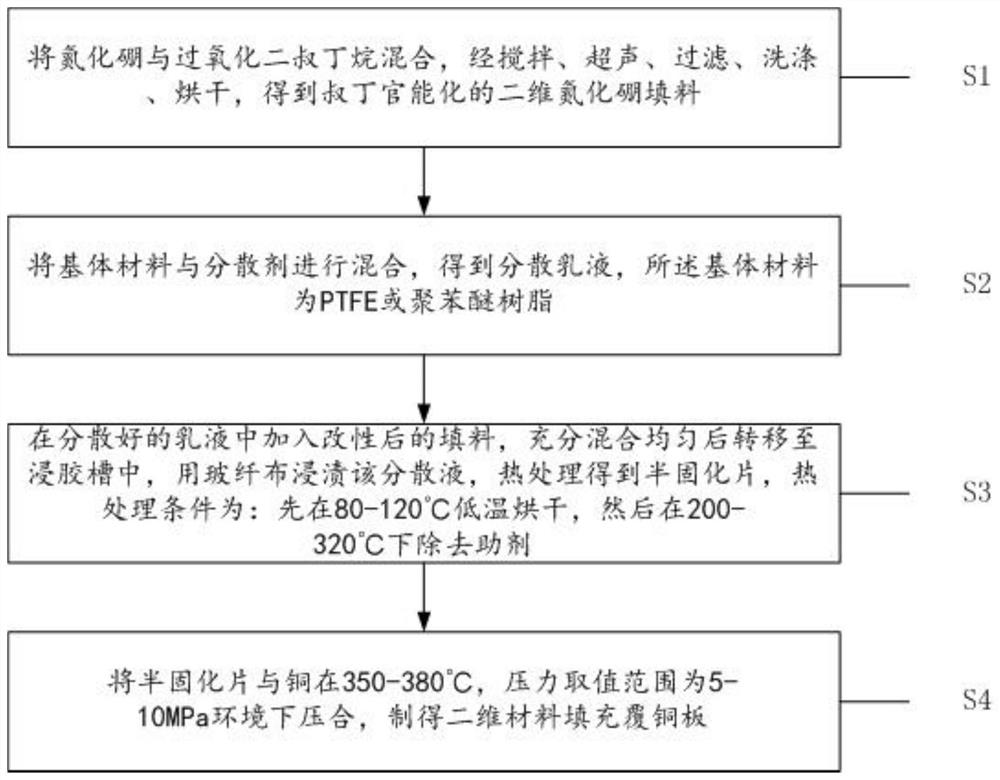

[0053] Please refer to figure 1 and image 3 , Embodiment 2 of the present invention is: a manufacturing process of a two-dimensional material filled copper clad laminate, comprising the following steps:

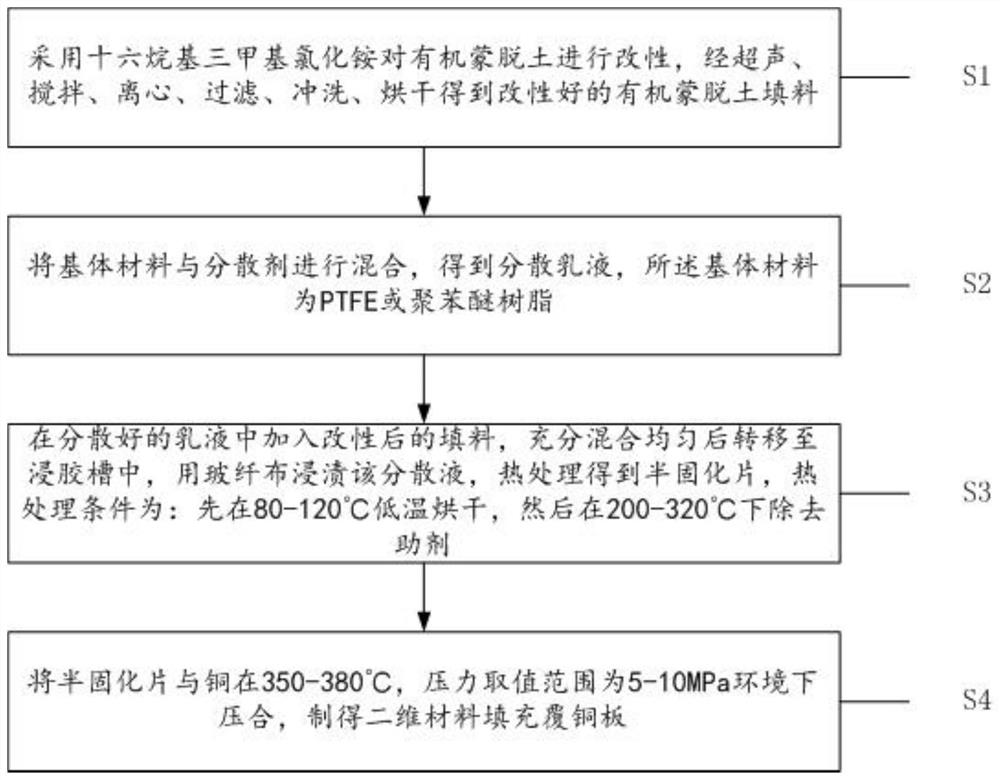

[0054] S1. The two-dimensional material is organic montmorillonite (OMMT), and the modifier is cetyltrimethylammonium chloride. The ratio is mixed, then add acetic acid to it to adjust it to acidity, stir at a speed of 600-800rpm and accompany with ultrasonic water bath for 8-12h; in the above dispersion, add cetyltrimethylammonium chloride, continue Ultrasound for 2-4 hours; then transfer the modified solution to a flask, raise the temperature to 50-80°C, stir mechanically for 10-12 hours, cool down to room temperature, and finally centrifugally purify the modified solution, filter it with a microporous membrane, and repeatedly use distilled water Rinse and dry to obtain modified OMMT;

[0055] S2. Mix the matrix material with a dispersant to obtain a dispersed emulsion....

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com