Method for improving toxicity resistance of microalgae in wastewater treatment process through brassinolide

Brassinolide, a technology for treating wastewater, applied in the directions of microorganism-based methods, sustainable biological treatment, chemical instruments and methods, etc., can solve the problem of decreased yield of additional products of microalgae, pollutant toxicity stress yield, energy consumption and the increase of training costs, etc., to achieve the effect of low cost, environmental friendliness and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Microalgae enrichment

[0062] Add 3LBG11 medium into a 5L photoreactor, and inoculate the cells of Chlorella, Scenedesmus, Chlamydomonas and Spirulina into the medium at a volume ratio of 15%, respectively, at 20°C, with a light-to-dark ratio of 16:8 and Cultivate at a rotational speed of 150r / min until the concentration of microalgae is 3×10 7 individual / mL.

[0063] Among them, the formula of BG11 medium is: 1.5g / LNaNO 3 , 2.86g / L H 3 BO 4 , 0.04g / L K 2 HPO 4 ·3H 2 O, 1.86g / LMnCl 2 , 0.075g / L MgSO 4 ·7H 2 O, 0.08g / L CuSO 4 , 0.036g / L CaCl 2 .2H 2 O, 0.22g / LZnSO 4 , 0.006g / L Lemon, 0.39g / LNa 2 MoO 4 , 0.006g / L ferric ammonium citrate, 0.05g / L Co(NO 3 ) 2 ·6H 2 O, 0.02g / LNaCO 3 , 0.001g / L EDTANa 2 .

Embodiment 2

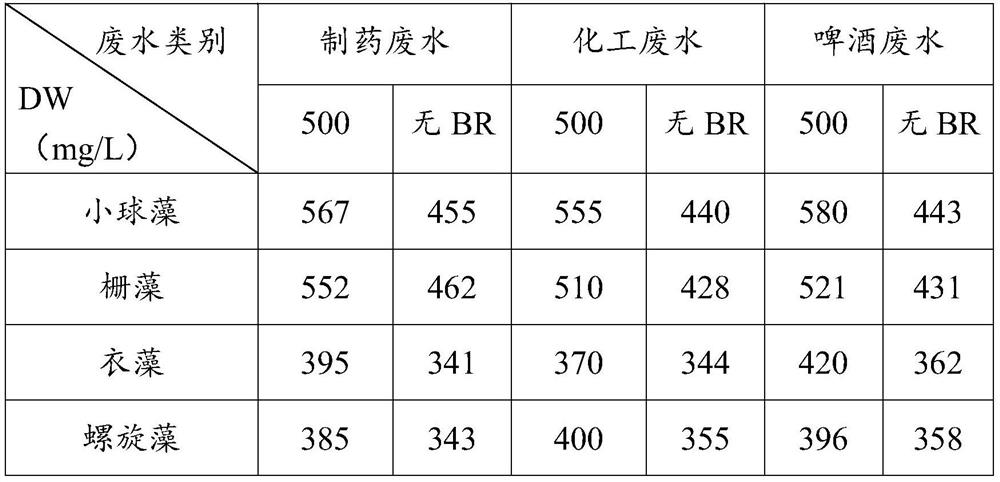

[0065] Improvement of microalgae biomass by brassinolide in wastewater culture

[0066] 1) Dilute the pharmaceutical wastewater, chemical wastewater and beer wastewater 10 times with distilled water, respectively, and then sterilize them, and measure the indicators of the wastewater to be treated;

[0067] 2) Add three kinds of sterilized waste water and 500 μg / L brassinosteroid respectively in the photoreactor, and use the stirring rod provided in the reactor to stir clockwise for 15 s and counterclockwise for 15 s in turn, Stir for 3 minutes until there is no obvious aggregation of microalgae clusters;

[0068] 3) After mixing, add the concentration of 3×10 7 Chlorella, Scenedesmus, Chlamydomonas and Spirulina in individual / mL with a volume fraction of 15%;

[0069] 4) Adjust the temperature to 20° C., use LED light to illuminate, the light-to-dark ratio is 16 / 8, and the rotation speed is 150 r / min to measure the biomass of microalgae after culturing for 72 hours.

[0070...

Embodiment 3

[0078] Improvement of microalgae biomass by brassinolide in wastewater culture

[0079] Concrete method is the same as embodiment 2, and in step 3), adding volume fraction is 5% Chlorella, Scenedesmus, Chlamydomonas and Spirulina respectively, and the results are shown in Table 3:

[0080] Brassinolide (500 μg / L) in different wastewaters in table 3 promotes the biomass of microalgae (5% microalgae)

[0081]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com