Acrylic acid low-temperature drying cathode electrophoretic paint and preparation method thereof

A technology of low temperature drying and cathodic electrophoresis, which is applied in the field of electrophoretic paint, can solve the problems of low weather resistance, cannot fully meet the needs, and short salt spray resistance time, and achieves good weather resistance, long salt spray time, and good leveling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

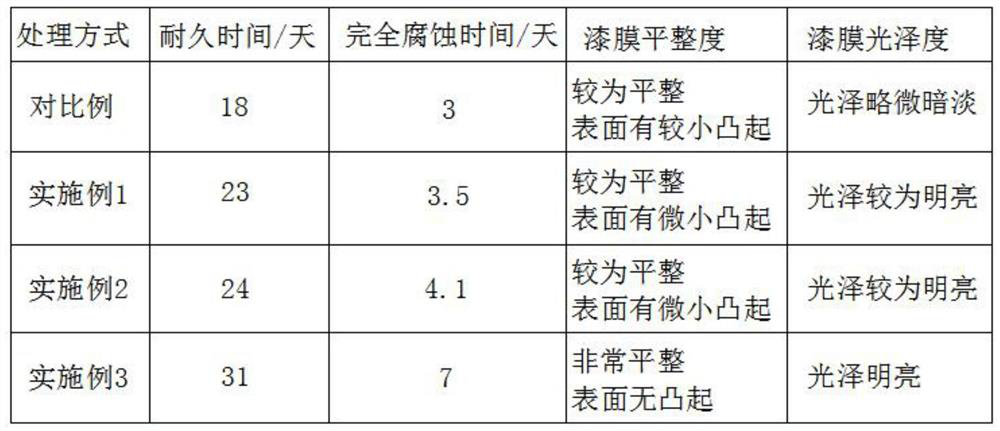

Examples

Embodiment 1

[0034] S1. Mix 110 parts of propylene glycol methyl ether, 115 parts of propylene glycol ethyl ether, 115 parts of propylene glycol propyl ether, 140 parts of propylene glycol butyl ether, 10 parts of butadiene, 215 parts of methyl acrylate, and 290 parts of 1-ethyl acrylate. into drip irrigation;

[0035] S2. When the temperature in the reactor rises to 85-90°C, 40 parts of 1-ethylene glycol monobutyl ether and 45 parts of 1-isopropanol are added dropwise, and the temperature is strictly controlled in the middle, and the drop is completed within 5.5-6.0 hours;

[0036] S3, then keep warm at 85-90°C for 1h;

[0037] S4. Mix 15 parts of 2-isopropanol and 15 parts of 2-ethyl acrylate evenly and start to add dropwise. The temperature in the reactor is kept at 85-90° C., and the dropwise is completed within 1 hour;

[0038] S5, keep warm at 85-90°C for 1.5h, and then measure the viscosity of the solvent;

[0039] S6, then lower the temperature to 50-55°C, add 70 parts of curing ...

Embodiment 2

[0045] S1. Mix 130 parts of propylene glycol methyl ether, 135 parts of propylene glycol ethyl ether, 135 parts of propylene glycol propyl ether, 160 parts of propylene glycol butyl ether, 30 parts of butadiene, 235 parts of methyl acrylate, and 310 parts of 1-ethyl acrylate. into drip irrigation;

[0046] S2. When the temperature in the reactor rises to 85-90°C, 60 parts of 1-ethylene glycol monobutyl ether and 65 parts of 1-isopropanol are added dropwise, and the temperature is strictly controlled in the middle, and the drop is completed within 5.5-6.0 hours;

[0047] S3, then keep warm at 85-90°C for 1h;

[0048] S4. Mix 35 parts of 2-isopropanol and 35 parts of 2-ethyl acrylate and start to drop them. The temperature in the reactor is kept at 85-90° C., and the drops are completed within 1 hour;

[0049] S5, keep warm at 85-90°C for 1.5h, and then measure the viscosity of the solvent;

[0050] S6, then lower the temperature to 50-55°C, add 90 parts of curing agent, 40 part...

Embodiment 3

[0056] S1. Mix 120 parts of propylene glycol methyl ether, 125 parts of propylene glycol ethyl ether, 125 parts of propylene glycol propyl ether, 150 parts of propylene glycol butyl ether, 20 parts of butadiene, 225 parts of methyl acrylate, and 300 parts of 1-ethyl acrylate. into drip irrigation;

[0057] S2. When the temperature in the reactor rises to 85-90°C, 50 parts of 1-ethylene glycol monobutyl ether and 55 parts of 1-isopropanol are added dropwise, and the temperature is strictly controlled in the middle, and the drop is completed within 5.5-6.0 hours;

[0058] S3, then keep warm at 85-90°C for 1h;

[0059] S4. Mix 25 parts of 2-isopropanol and 25 parts of 2-ethyl acrylate evenly and start to add dropwise. The temperature in the reactor is kept at 85-90° C., and the dropwise is completed within 1 hour;

[0060] S5, keep warm at 85-90°C for 1.5h, and then measure the viscosity of the solvent;

[0061] S6, then lower the temperature to 50-55°C, add 80 parts of curing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com