CoNiCrCu solid solution for heterogeneous interface bonding and preparation method and application thereof

A heterogeneous interface and solid solution technology, applied in the direction of additive processing, etc., can solve the problems of reducing joint strength, reducing welded joint performance, affecting the strength of steel-aluminum dissimilar metal connection materials, etc., to achieve high connection interface strength and hardness, The effect of reducing the residual stress level and relieving the thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides a method for preparing the above-mentioned CoNiCrCu solid solution for heterogeneous interface bonding, which specifically includes the following process steps:

[0046] (1) Ingredients:

[0047] Metal cobalt, metal chromium, metal nickel, and metal copper are used as raw materials, and are prepared according to the target composition;

[0048] (2) Melting:

[0049] Add the prepared metal cobalt, metal chromium, metal nickel, and metal copper into the intermediate frequency induction furnace, and heat it to melt it. In this smelting step, a small amount of formulated metal cobalt, metal chromium, metal nickel, and metal copper ingredients are added into the intermediate frequency induction furnace for smelting first, and then the remaining ingredients are added to the molten alloy solution as supplementary materials. When feeding the feeding material, the temperature in the medium frequency induction furnace is controlled at 1500°C ...

Embodiment 1

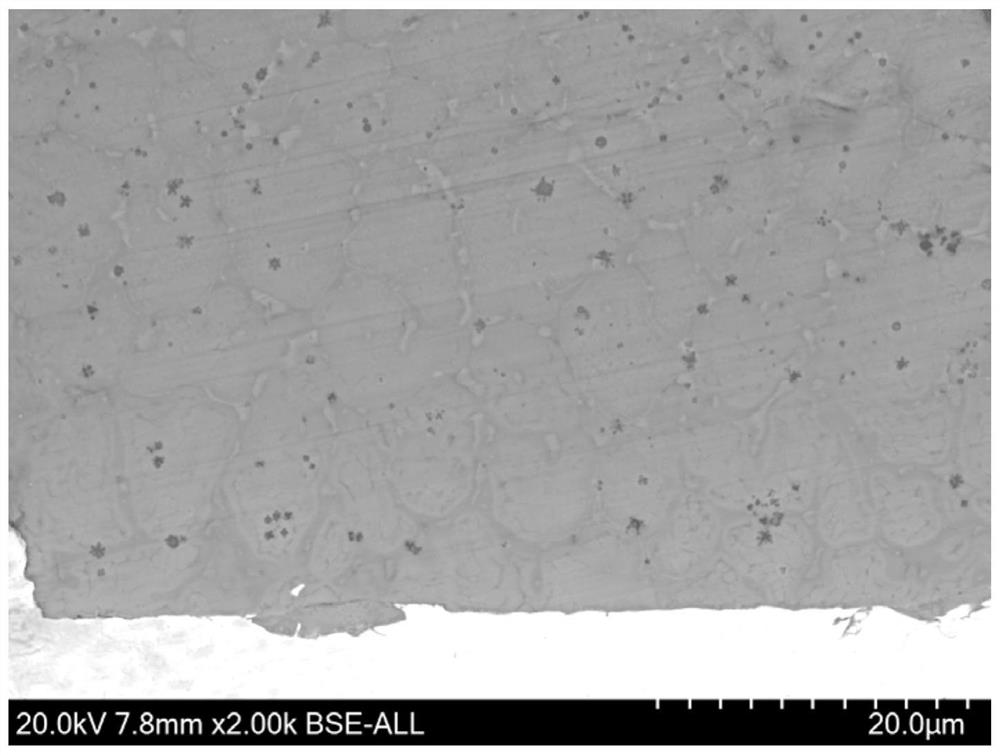

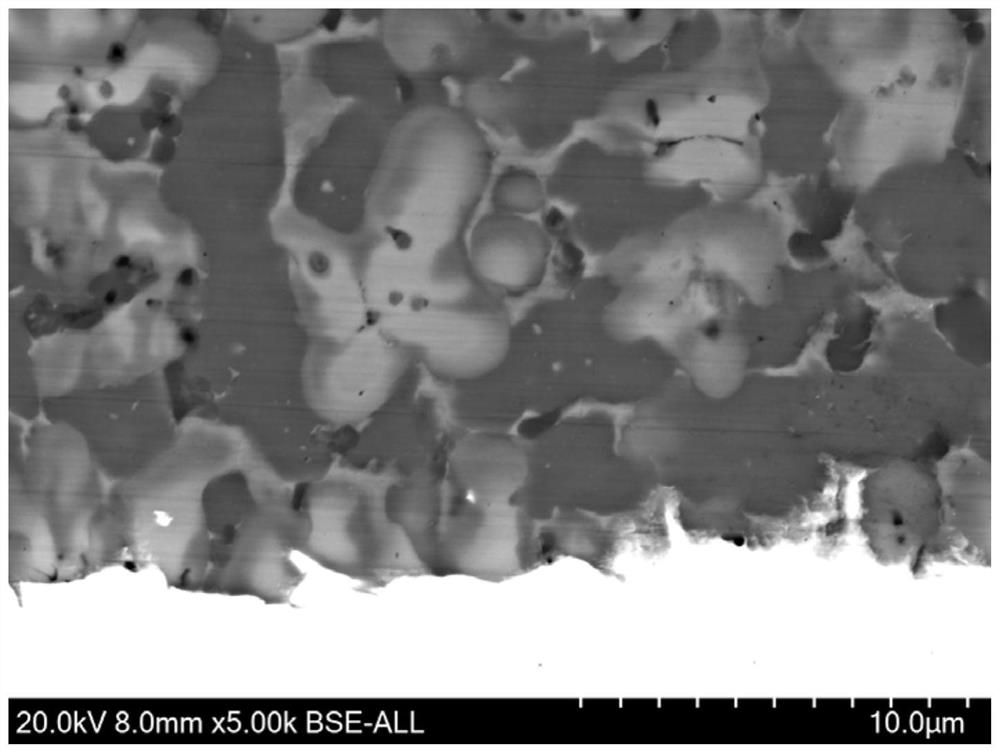

[0061] The ingredients are prepared according to the following proportions, in terms of weight percentage, including: 25% cobalt, 22% chromium, 25% nickel, and 28% copper. Add the prepared metal cobalt, metal chromium, metal nickel, and metal copper into the intermediate frequency induction furnace, and heat it to melt it. The temperature in the intermediate frequency induction furnace is controlled at about 1520°C. After the ingredients are adjusted to pass before the furnace, it is released from the furnace, and the temperature of the furnace is 1460°C.

[0062] The alloy melt is atomized to prepare alloy powder, the atomization medium is argon, and the atomization pressure is 4MPa. A far-infrared dryer is used to dry the atomized alloy powder, and the drying temperature is 210°C. Then the particle size range of 100 is sieved by the sieving machine ~ 350 mesh powder is used as finished powder. The finished powder is directly used as a powdery CoNiCrCu solid solution, and ...

Embodiment 2

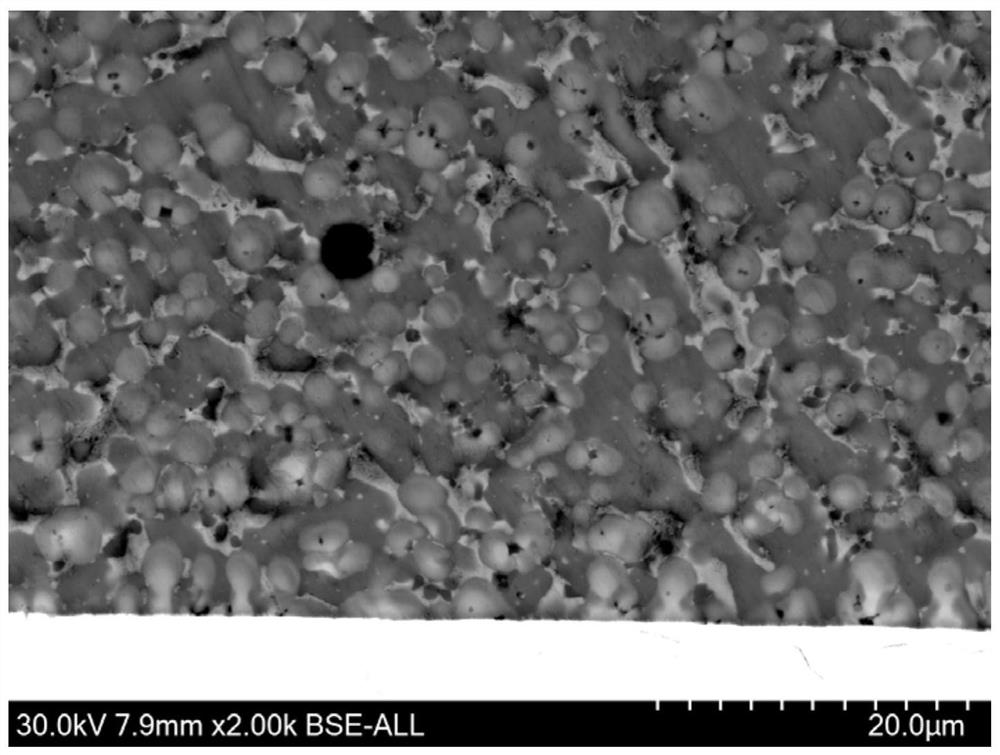

[0079] The ingredients are prepared according to the following proportions, in terms of weight percentage, including: 30% cobalt, 27% chromium, 30% nickel and 13% copper. Add the prepared metal cobalt, metal chromium, metal nickel, and metal copper into the intermediate frequency induction furnace, and heat it to melt it. The temperature in the intermediate frequency induction furnace is controlled at about 1520°C. After the ingredients are adjusted to pass before the furnace, it is released from the furnace, and the temperature of the furnace is 1460°C.

[0080] The alloy melt is atomized to prepare alloy powder, the atomization medium is argon, and the atomization pressure is 4MPa. A far-infrared dryer is used to dry the atomized alloy powder, and the drying temperature is 210°C. Then the particle size range of 100 is sieved by the sieving machine ~ 350 mesh powder is used as finished powder. The finished powder is directly used as a powdery CoNiCrCu solid solution, and u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com