Method of preventing gas leakage of laser gyroscope based on surface CVD grown graphene

A technology of gas leakage and laser gyro, which is applied in the test of fluid tightness, by detecting the appearance of fluid at the leakage point, gaseous chemical plating and other directions, can solve the problems that helium atoms cannot be prevented from permeating and escaping, so as to prevent permeation and escape, Stable performance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

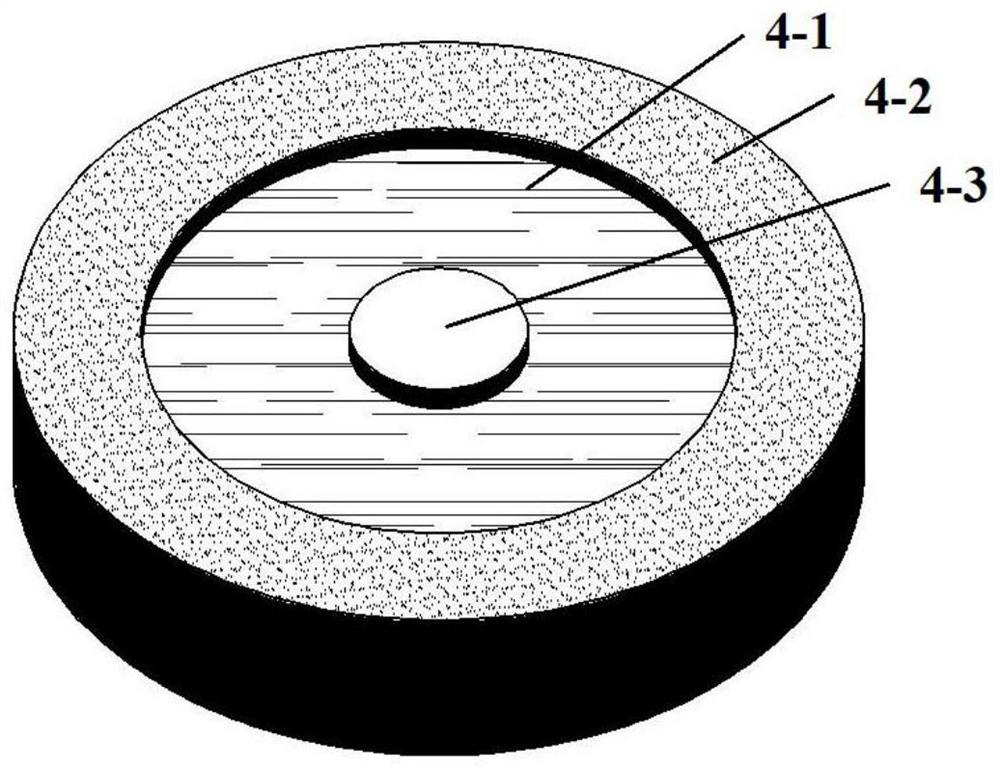

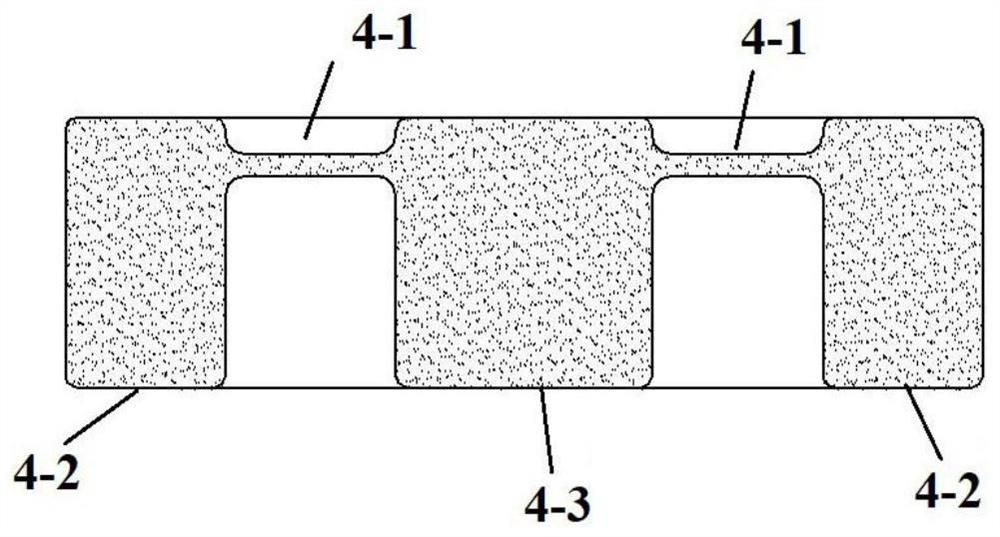

[0036] Embodiment 1: This embodiment takes the cavity length control mirror (raw material is quartz glass) as an example.

[0037] A method for preventing laser gyroscope gas leakage based on surface CVD growth graphene method, comprising the following steps:

[0038] Copper or nickel with a thickness of several nanometers is plated by magnetron sputtering in the region where the cavity length control mirror needs to grow graphene

[0039] Use the solution, the solution component is H 2 SO 4 : 30%H 2 o 2 =7:3, the length of the soaking chamber is controlled for 2-5 hours, and then ultrasonic cleaning is performed in deionized water, ethanol and acetone in sequence to remove any organic and inorganic impurities on the surface;

[0040] Use a magnetron sputtering device to plate copper or nickel with a thickness of several nanometers on the surface where graphene needs to grow.

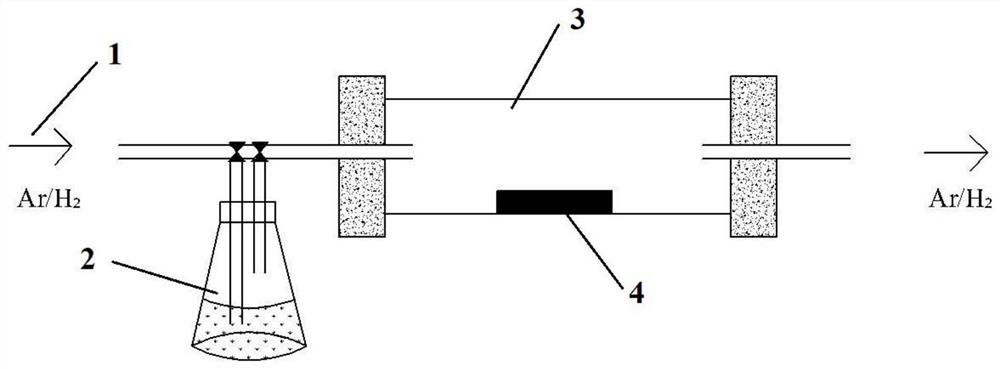

[0041] Graphene Growth by CVD

[0042] Use solvents such as ethanol, ether or acetone to ultra...

Embodiment 2

[0058] Embodiment 2: The cavity length control mirror is replaced with other parts of the laser gyroscope that are prone to leaking glass components, and the reaction conditions are appropriately changed to realize the growth of graphene by CVD method, which can prevent helium leakage from other parts of the laser gyroscope.

Embodiment 3

[0059] Embodiment 3: Graphene can be directly grown on the surface of the cavity length control mirror without plating a metal film with a nanometer thickness, and the reaction conditions can be appropriately changed to realize the growth of graphene by CVD method, which can prevent helium leakage from other parts of the laser gyroscope.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com