Inverted light-emitting diode chip and preparation method thereof

A light-emitting diode and chip technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of poor thermal conductivity of sapphire, reduced product reliability, and small total reflection angle of outgoing light, so as to improve the current expansion effect and increase the Recombination area, the effect of improving internal quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

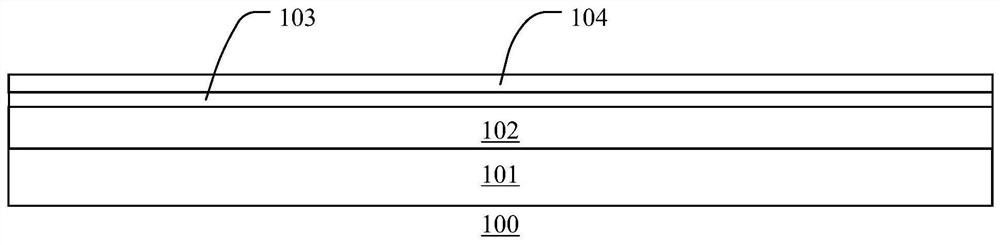

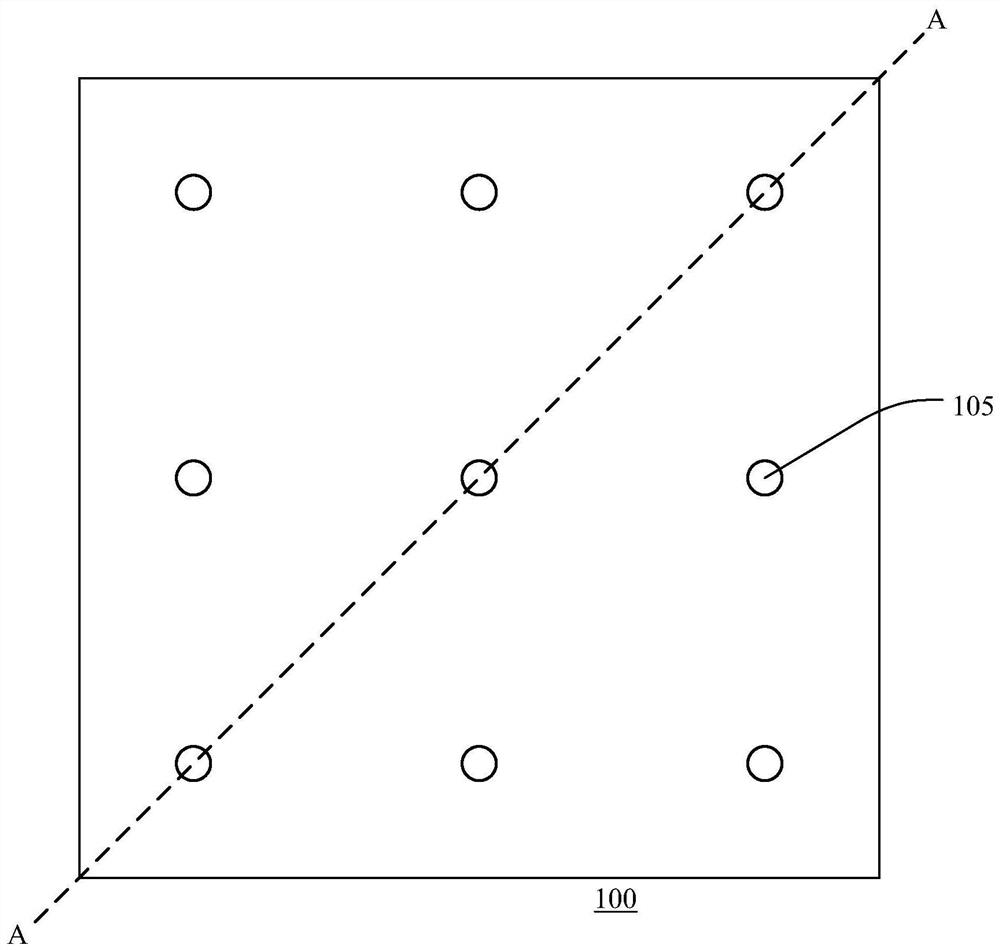

[0098] Such as Figure 9 to Figure 14 As shown, among them, Figure 9 and Figure 12 The dotted line part does not exist, it is only for clearly expressing the structural relationship between the adjacent upper and lower floors. In the second embodiment of the present invention, the flip-chip light-emitting diode chip needs to stack N-type doped gallium nitride layer 102', active layer 103', P-type doped gallium nitride layer 102', P-type doped GaN layer 104' to form a basic semiconductor structure of a flip-chip LED. Further, a current blocking layer 105' is formed on the P-type doped gallium nitride layer 104'. Further, a transparent conductive layer 106' is conformally deposited on the P-type doped gallium nitride layer 104' and the current blocking layer 105'. Further, a layer of photoresist is coated on the transparent conductive layer 106', and then the photoresist is exposed and developed to form an array of openings on the photoresist. Further, part of the transpa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com