High-flexibility super non-slip wear-resistant foam material and preparation method thereof

A technology of super anti-slip wear-resistant and foaming materials, which is applied in the field of shoe manufacturing, can solve the problems of no wear-resistant anti-slip data results and no mentions, and achieve the effects of short cycle, easy operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

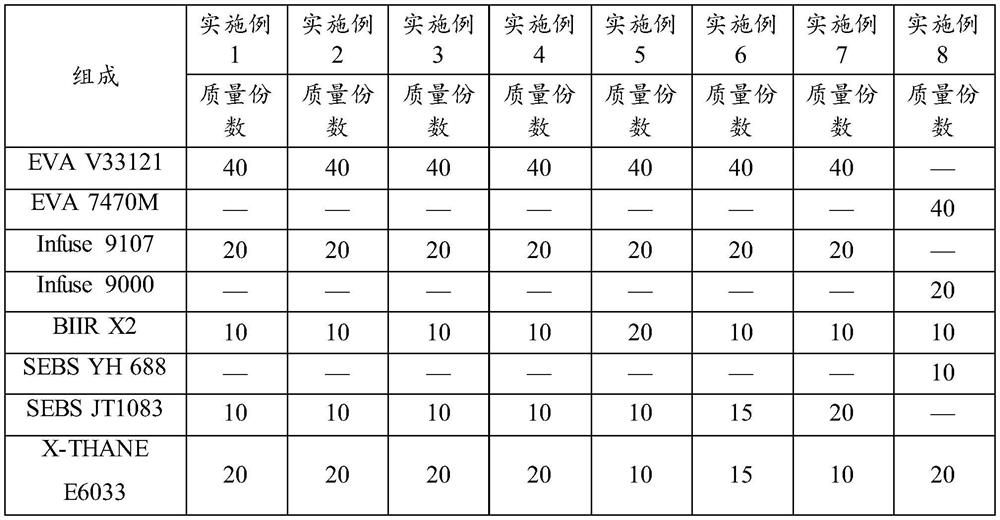

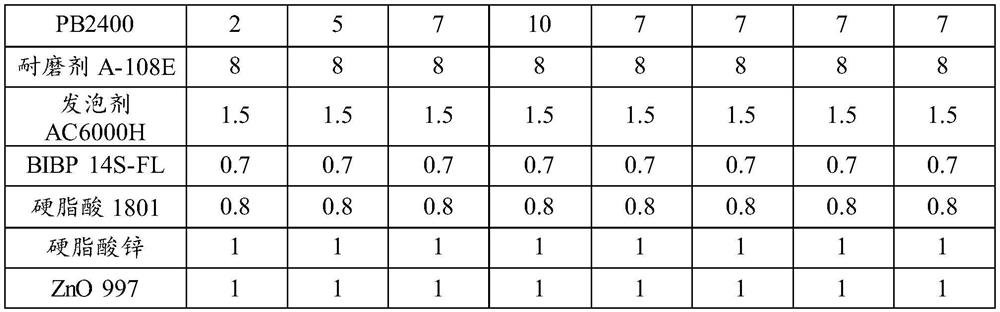

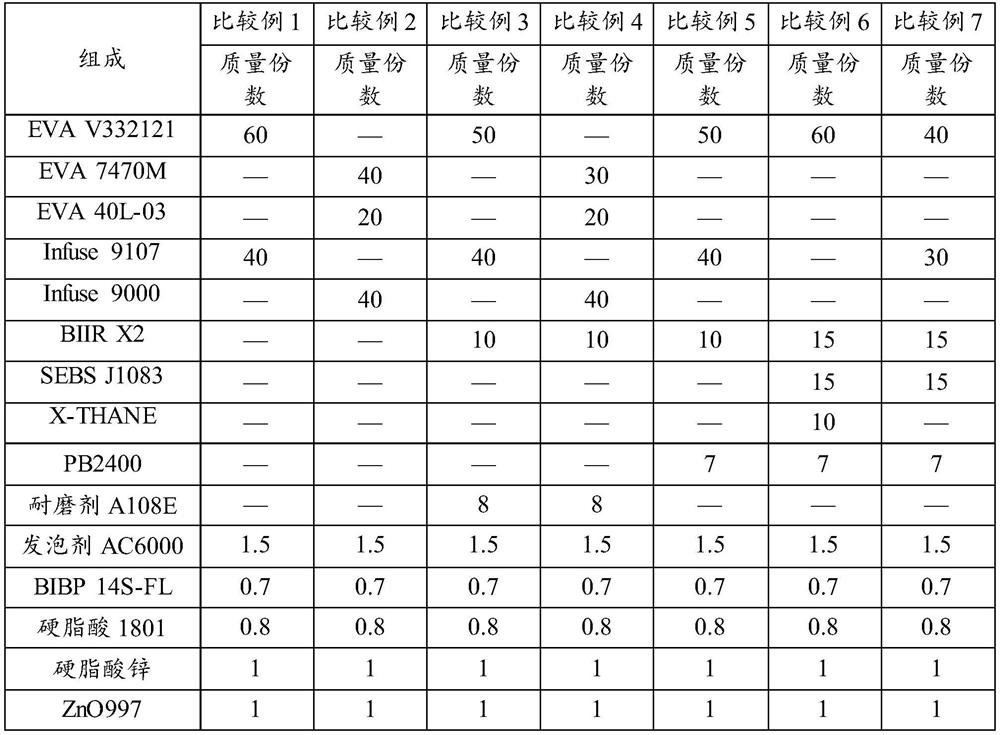

Method used

Image

Examples

preparation example Construction

[0062] The present invention also provides a preparation method of the highly flexible super anti-slip wear-resistant foam material described in the above technical solution, comprising the following steps:

[0063] a) mixing the main plastic material, polyisobutylene, anti-wear agent, peroxide crosslinking agent, foaming agent, zinc oxide, stearic acid and zinc stearate, and kneading to obtain a mixture;

[0064] b) The mixed material obtained in step a) is sequentially subjected to material making, foaming and baking to obtain a highly flexible, super anti-slip and wear-resistant foam material.

[0065] In the invention, firstly, the main plastic material, polyisobutylene, anti-wear agent, peroxide crosslinking agent, foaming agent, zinc oxide, stearic acid and zinc stearate are mixed and kneaded to obtain the mixture. In the present invention, the plastic main material, polyisobutylene, anti-wear agent, peroxide crosslinking agent, foaming agent, zinc oxide, stearic acid an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com