CoCrNiCuMn-TiN-TiC-WC composite material and preparation method thereof

A composite material, CH4N2O technology, applied in the field of material composites, can solve problems such as poor bonding, and achieve the effect of improving hardness and toughness, good mass transfer ability, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The invention also discloses a preparation method of a CoCrNiCuMn-TiN-TiC-WC composite material, comprising the following steps:

[0054] S1, prepare CoCrNiCuMn powder with finer than 150nm;

[0055] Co, Cr, Ni, Cu, Mn powders are ball milled to obtain CoCrNiCuMn powders with a diameter of 150nm.

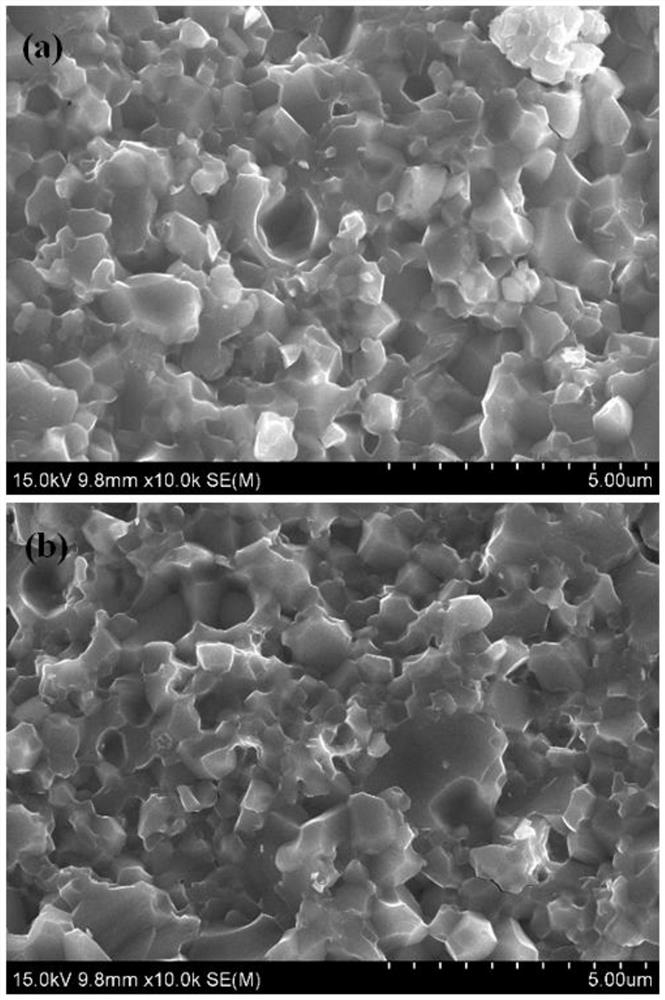

[0056] S2, prepare 150nm finer TiNx powder;

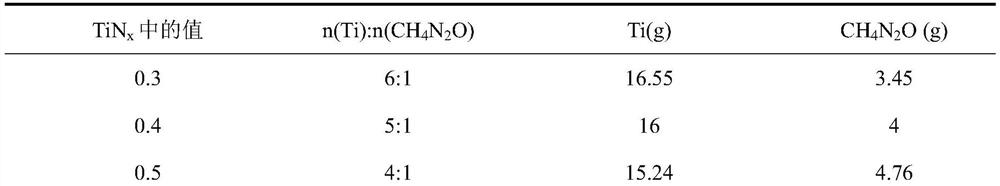

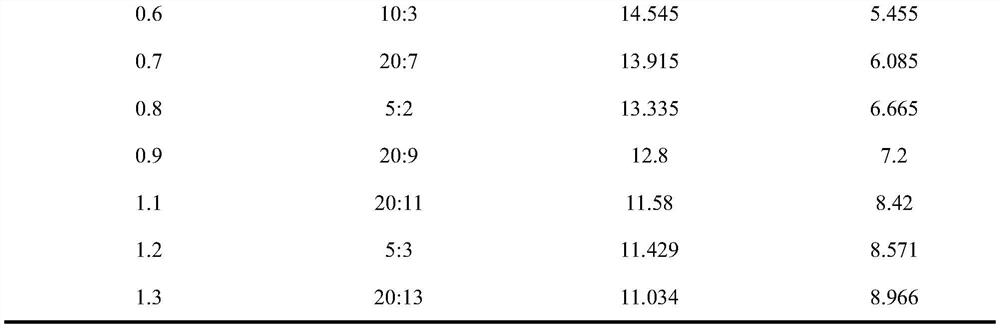

[0057] Ti powder and CH in preset molar ratio 4 N 2 O is ball milled to produce fine TiNx powders with a thickness of 150nm, wherein x=0.3~0.9 or x=1.1~1.3;

[0058] S3, preparing TiC powder finer than 150nm;

[0059] The TiC powder is ball-milled to obtain TiC powder finer than 150nm;

[0060] S4, preparing 150nm finer WC powder;

[0061] Ball mill the WC powder to obtain WC powder with a fineness of 150nm or less;

[0062] S5. CoCrNiCuMn-TiN-TiC-WC composite material is obtained by mixing materials, pre-pressing, and vacuum hot-pressing sintering;

[0063] Weigh the CoCrNiCuMn powder with a mass percentage of 5-20wt.%, t...

Embodiment 1

[0091] The weighing of the raw material formula is carried out according to the following percentages:

[0092] Table 3 prepares the raw material and its proportion of 40g CoCrNiCuMn-TiN-TiC-WC composite material

[0093]

[0094] S1. In a glove box filled with argon, mix 4.05gCo, 3.65gCr, 4.04gNi, 4.41gCu and 3.85gMn into a WC cemented carbide ball mill jar. The mass ratio of the ball to the material is 10:1, and the speed is 600r / min, the ball milling time is 50h, stop every 5h for 30min to dissipate heat, stop every 10h to scrape off the raw materials sticking to the ball and the inner wall of the tank, and then continue ball milling to obtain CoCrNiCuMn powder with a fineness of 150nm or less.

[0095] S2. Mix 16.55g Ti powder and 3.45gCH in a glove box filled with argon 4 N 2 O is put into a WC cemented carbide ball mill tank, the mass ratio of the ball and the material is 10:1, the rotating speed is 500r / min, the ball milling time is 30h, and the machine is stopped...

Embodiment 2

[0103] The weighing of the raw material formula is carried out according to the following percentages:

[0104] Table 5 prepares the raw material and its proportion of 40g CoCrNiCuMn-TiN-TiC-WC composite material

[0105]

[0106] S1. Mix 4.05gCo, 3.65gCr, 4.04gNi, 4.41gCu and 3.85gMn into a WC cemented carbide ball mill in a glove box filled with argon. The mass ratio of the ball to the material is 20:1, and the speed is 300r / Min, the ball milling time is 20h, stop every 5h for 30min to dissipate heat, stop every 10h to scrape off the raw materials sticking to the ball and the inner wall of the tank, and then continue the ball milling to obtain CoCrNiCuMn powder finer than 150nm.

[0107] S2, 16gTi powder and 4gCH were mixed in a glove box filled with argon 4 N 2 O is put into a WC cemented carbide ball mill tank, the mass ratio of the ball and the material is 20:1, the rotating speed is 200r / min, the ball milling time is 60h, the machine is shut down for 30min every 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com