Chemical-energy-driven nano motor, power providing method thereof and nano robot

A nanorobot and engine technology, applied in the field of nanotechnology, can solve the problems of inability to guarantee the energy of nanorobots, less kinetic energy, limited activity and catalytic efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

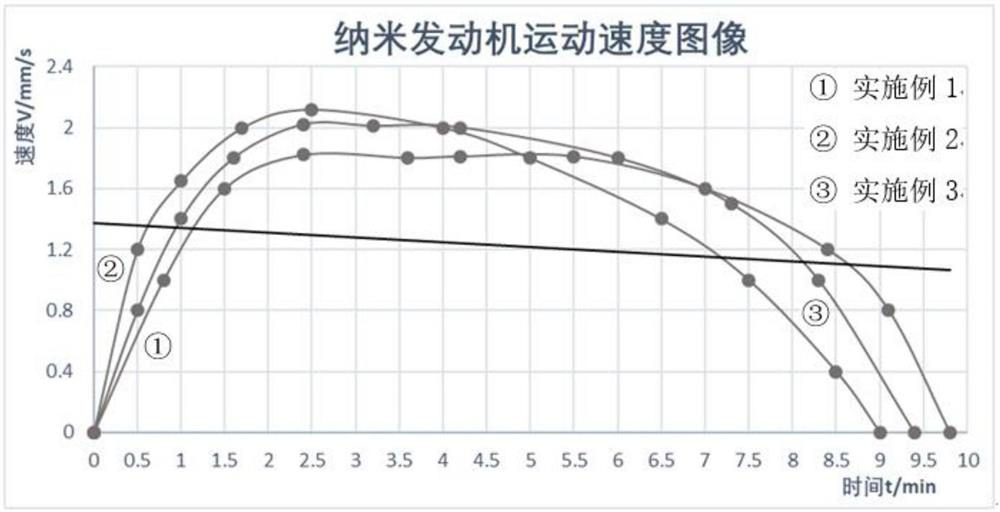

Embodiment 1

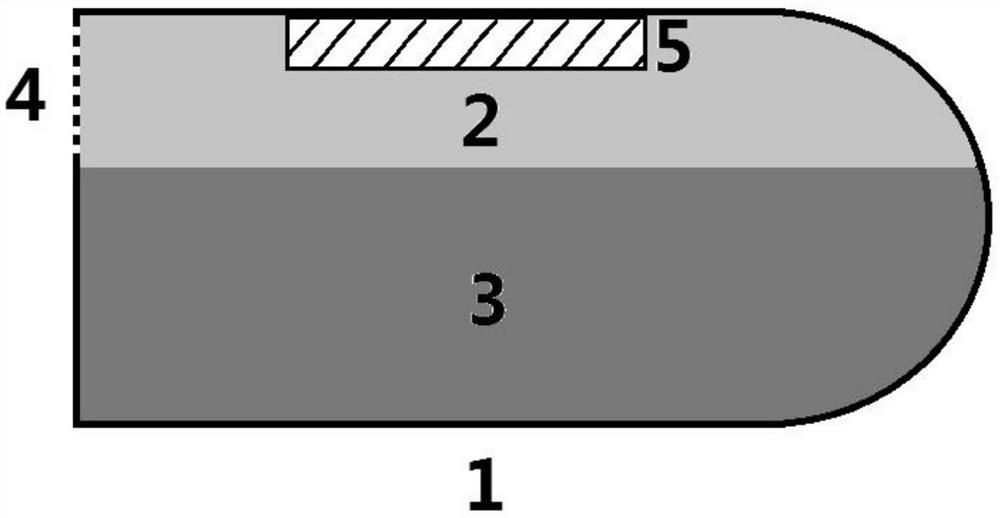

[0052] 1) The structure of the nanoengine:

[0053] a kind of like figure 1 The nano-engine with the structure shown includes: a housing 1, the material of the housing 1 is titanium dioxide, and the thickness is 120nm; one end of the housing 1 along the horizontal direction is hemispherical, and the housing part connected to the hemispherical shape is a cylinder The inner diameter of the hemispherical part and the cylindrical part of the shell 1 is 480nm, and the axial length of the cylindrical part is 820nm; the lower part of the shell 1 is a water layer 3, and the height of the water layer 3 is 340nm, filled with distilled water; the shell 1 The inner upper part is the oil layer 2, the height of the oil layer 2 is 140nm, filled with ρ=0.8g / cm 3 kerosene; the upper half of the opposite end of the shell 1 (with the interface between the oil layer 2 and the water layer 3) is the opening 4 of the shell 1, and the opening 4 is covered with a cellulose semipermeable membrane , t...

Embodiment 2

[0068] 1) The structure of the nanoengine:

[0069] a kind of like figure 1 The nano-engine with the structure shown includes: a housing 1, the material of the housing 1 is titanium dioxide, and the thickness is 120nm; one end of the housing 1 along the horizontal direction is hemispherical, and the housing part connected to the hemispherical shape is a cylinder The inner diameter of the hemispherical part and the cylindrical part of the shell 1 is 480nm, and the axial length of the cylindrical part is 820nm; the lower part of the shell 1 is a water layer 3, and the height of the water layer 3 is 340nm, filled with distilled water; the shell 1 The inner upper part is the oil layer 2, the height of the oil layer 2 is 140nm, filled with ρ=0.8g / cm 3kerosene; the upper half of the opposite end of the shell 1 (with the interface between the oil layer 2 and the water layer 3) is the opening 4 of the shell 1, and the opening 4 is covered with a cellulose semipermeable membrane , th...

Embodiment 3

[0084] 1) The structure of the nanoengine:

[0085] a kind of like figure 1 The nano-engine with the structure shown includes: a housing 1, the material of the housing 1 is titanium dioxide, and the thickness is 120nm; one end of the housing 1 along the horizontal direction is hemispherical, and the housing part connected to the hemispherical shape is a cylinder The inner diameter of the hemispherical part and the cylindrical part of the shell 1 is 480nm, and the axial length of the cylindrical part is 820nm; the lower part of the shell 1 is a water layer 3, and the height of the water layer 3 is 340nm, filled with distilled water; the shell 1 The inner upper part is the oil layer 2, the height of the oil layer 2 is 140nm, filled with ρ=0.8g / cm 3 kerosene; the upper half of the opposite end of the shell 1 (with the interface between the oil layer 2 and the water layer 3) is the opening 4 of the shell 1, and the opening 4 is covered with a cellulose semipermeable membrane , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com