Processing method of high-proportion total-nutrient purple sweet potato whole flour coarse cereal steamed buns

A purple sweet potato powder and processing method technology, applied in the field of food processing, can solve the problems of poor dough performance, difficult shaping, hard steamed bread, etc., achieve attractive color and sweet flavor, improve elasticity and cohesiveness, and satisfy nutrition quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] A method for processing high-proportion full-nutrition purple sweet potato whole flour miscellaneous grain steamed buns is specifically prepared according to the following steps:

[0076] 1. Weigh raw materials: Weigh 400g of purple sweet potato powder, 1000g of wheat flour, 60g of gluten powder, 80g of glutinous rice flour, 60g of millet flour, 50g of highland barley flour, and 50g of buckwheat flour in sequence, and mix them evenly to obtain a composite grain powder;

[0077] 2. Activate yeast: Weigh 6-8g of high-activity dry yeast powder, add 20 times the amount of warm water at 30-32°C, stir it into a uniform suspension, and activate it at 30-32°C for 20 minutes for later use;

[0078] 3. Mixing of raw materials: Take 80% of the above compound powder and slowly pour it into the dough mixer, add the activated yeast suspension, and then add 500-600g of warm water at 30-32°C;

[0079] 4. Add oil: Weigh 40g of lard and add it to the dough mixer, stir the mixture at a me...

Embodiment 2

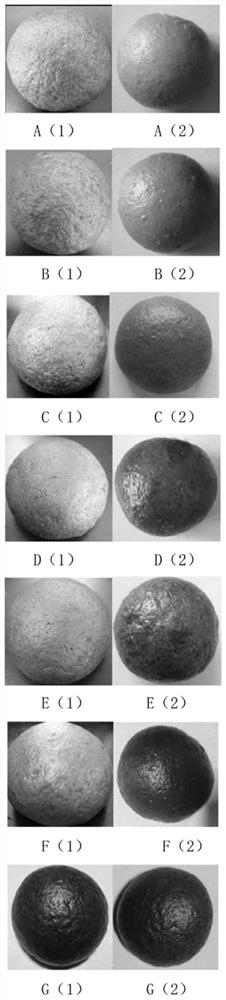

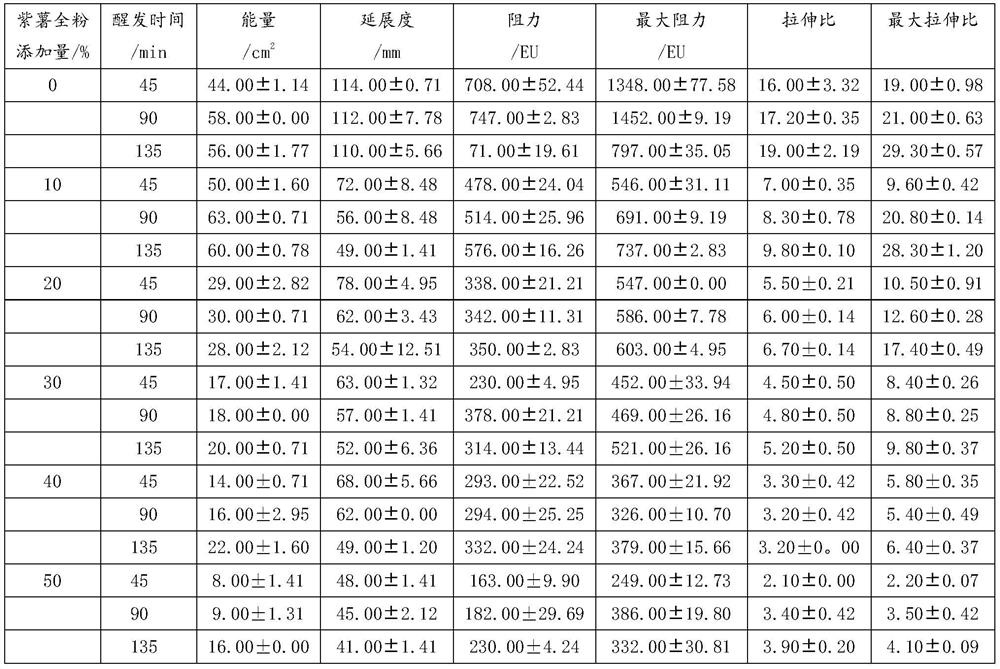

[0087]In terms of technology, the method in Example 1 is still used for the processing of steamed buns. In terms of formula, two systems are used as the basis. One system uses only purple sweet potato powder and wheat flour as raw materials, and the other system uses purple potato whole powder, Wheat flour, gluten flour, glutinous rice flour, millet flour, highland barley flour and buckwheat flour are used as raw materials. In the above two systems, the addition of purple potato powder is 20%, 25 %, 30%, 35%, 40%, 45% and 50% were adjusted, and then the processed steamed buns were compared with the surface and internal porosity respectively. For specific comparison results, see figure 1 , figure 2 , figure 1 and figure 2 (1) corresponds to using only purple sweet potato powder and wheat flour as raw materials; (2) corresponds to using miscellaneous grain compound powder as raw materials, and A, B, C, D, E, F, G correspond to purple sweet potato respectively The adding amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com