Method for preparing dust-settling and dust-absorbing material from non-metallic minerals and cement plant production raw materials

A non-metallic mineral, cement plant technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

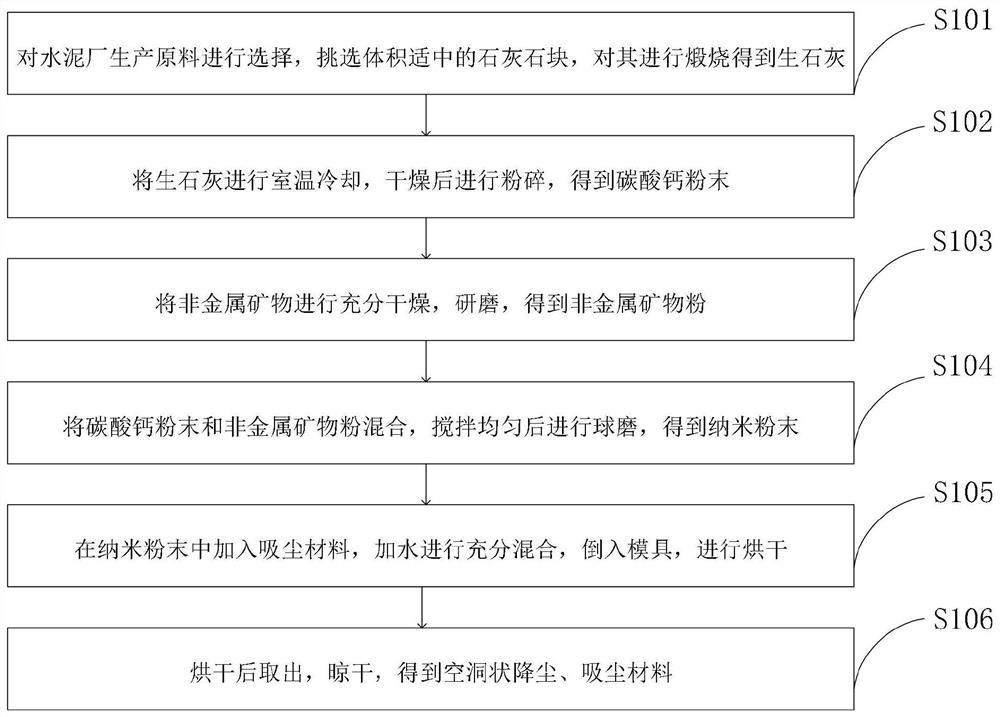

Method used

Image

Examples

Embodiment 1

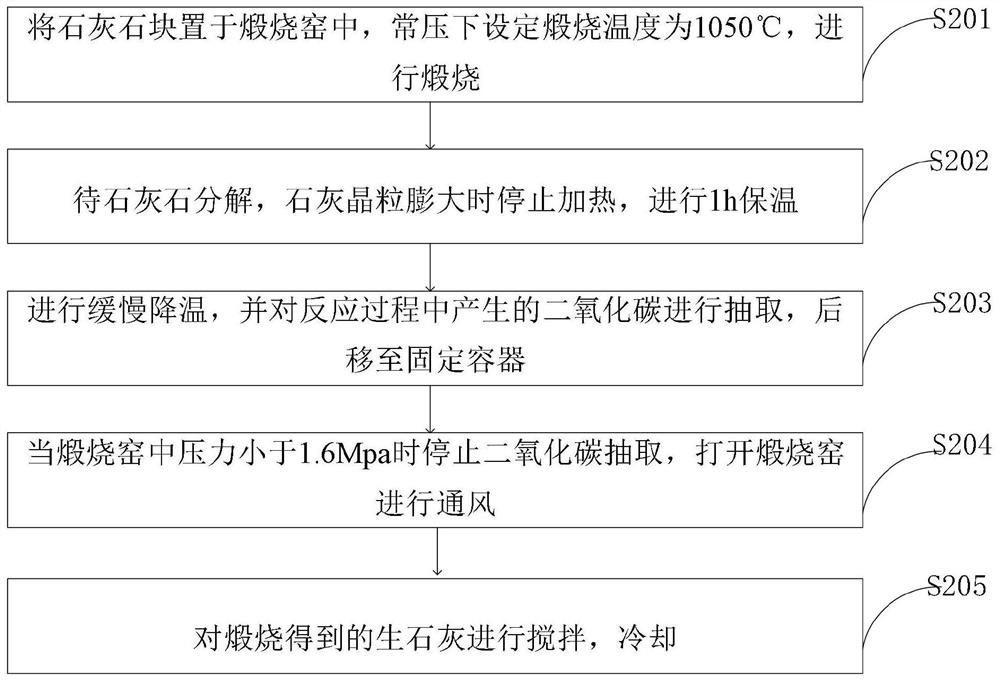

[0074] Select limestone blocks with a moderate volume in the cement plant, about 10cm×10cm×20cm in size, and calcinate them to obtain quicklime;

[0075] cooling the calcined quicklime to room temperature, drying and pulverizing to obtain calcium carbonate powder;

[0076] Fully drying and grinding the granite to obtain granite powder;

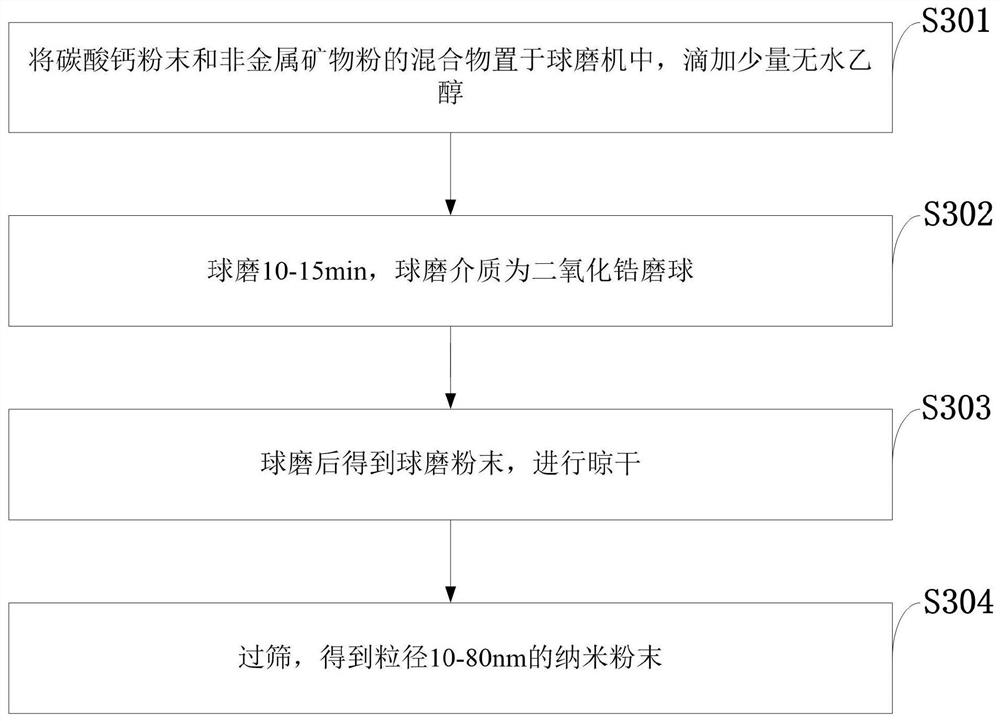

[0077] Mix calcium carbonate powder and granite powder, stir evenly, and then ball mill to obtain nano powder with a particle size of 10-80nm;

[0078] Add dust-absorbing materials to the nano-powder, add water to mix thoroughly, pour into the mold, and dry;

[0079] After drying, take it out and dry it to obtain a hollow-shaped dust-suppressing and dust-absorbing material.

Embodiment 2

[0081] The detection of adsorption force is carried out on the cavity-shaped dust-falling and dust-absorbing materials prepared in Example 1.

[0082] The main parameters that characterize the porous structure are porosity, average pore size, maximum pore size, pore size distribution, pore shape and specific surface area. In addition to the material, the porous structure parameters of the material have a decisive impact on the mechanical properties and various performances of the material. Since the pores are formed by the accumulation, compaction and sintering of powder particles, the physical and chemical properties of the raw material powder, especially the size, distribution and shape of the powder particles, are the main factors that determine the porous structure and even the final use performance.

[0083] In the embodiment of the present invention, the detection of the adsorption force of hollow dust-falling and dust-absorbing materials includes particle size, porosity,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com