3,3',4,4'-biphenyl tetraformyl tetraoctylamine, and preparation method and application thereof

A technology of biphenyl tetracarboxyl tetraoctylamine and biphenyl tetracarboxylic acid, which is applied in the field of 3,3′,4,4′-biphenyltetracarboxyl tetraoctylamine and its preparation, can solve the problem of unfriendly environment, Poor viscosity-increasing performance, large amount of addition, etc., to achieve the effect of ensuring purity and yield, low production cost, and strong viscosity-increasing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

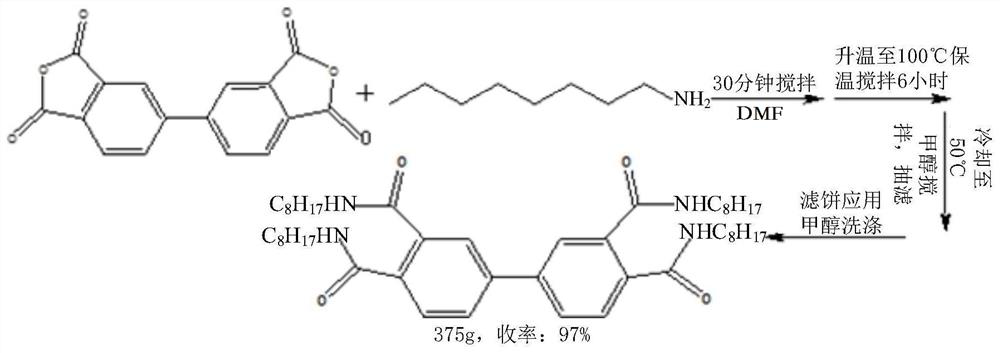

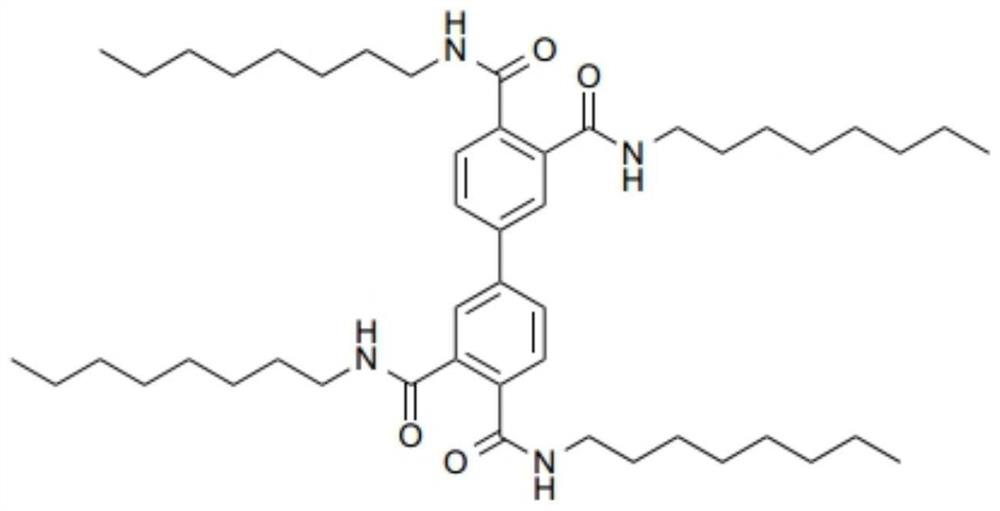

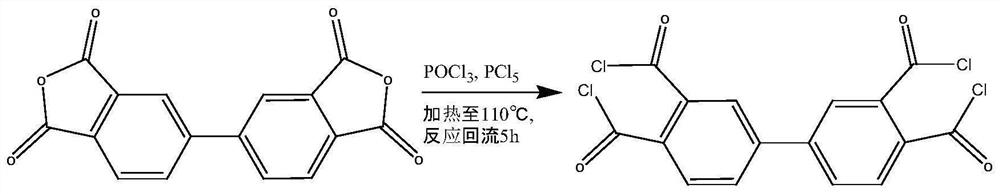

[0053]A specific embodiment discloses the preparation method of 3,3',4,4'-biphenyltetraformyltetraoctylamine (hereinafter referred to as method one), such as figure 2 shown, including the following steps:

[0054] Step 11: adding solvent and n-octylamine to the reaction vessel;

[0055] Step 12: Add 3,3′,4,4′-biphenyltetracarboxylic dianhydride to react, the reaction temperature is 80-150°C, and the reaction time is 5-15h; the reaction process is shown in 2;

[0056] Step 13: cooling to 30-50°C, adding a precipitation agent to precipitate the product;

[0057] Step 14: Cool to 20-40° C., and filter with suction to obtain 3,3′,4,4′-biphenyltetracarboxyltetraoctylamide.

[0058] In the invention, by optimizing the reaction conditions, the purity of the prepared product is greater than 98%, the yield is as high as 95.6%, and the viscosity-increasing performance is good, and the product quality is stable. Compared with the existing thickener phosphoric acid ester, the viscosit...

Embodiment 1

[0082] In this example, 3,3′,4,4′-biphenyltetracarboxyltetraoctylamide was prepared by method one.

[0083] Put 400 grams of DMF and 250 grams of n-octylamine into a 2-liter four-neck glass flask. Slowly add 60 grams of 3,3',4,4'-biphenyltetracarboxylic dianhydride with stirring, stir at 120°C for 8 hours after the addition, cool to 50°C, add 600 grams of methanol dropwise, and a large amount of solids precipitate out. Cool to 30°C, filter with suction, wash the filter cake with 100 mL of methanol, and dry to obtain 155 grams of solid, with a product purity of 99% and a yield of 95.6%.

Embodiment 2

[0085] In this example, 3,3′,4,4′-biphenyltetracarboxyltetraoctylamide was prepared by method one.

[0086] 350 grams of DMF and 207 grams of n-octylamine were put into a 2-liter four-neck glass flask. Slowly add 60 grams of 3,3',4,4'-biphenyltetracarboxylic dianhydride with stirring, stir at 150°C for 5 hours after the addition, cool to 30°C, add 400 grams of methanol dropwise, and a large amount of solids precipitate out. Cool to 30°C, filter with suction, wash the filter cake with 100mL of methanol, and dry to obtain 150g of solid with a product purity of 98% and a yield of 92.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com