Flame-retardant antistatic PVC wire and cable material and preparation method thereof

A wire and cable material and anti-static technology, which is applied in the field of flame-retardant and anti-static PVC cable material and its preparation, can solve the problems of increasing the amount of flame retardant added, high production cost, and decreasing oxygen barrier index, so as to improve the flame retardant, Reduce production cost, good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0032] 1. Mixture:

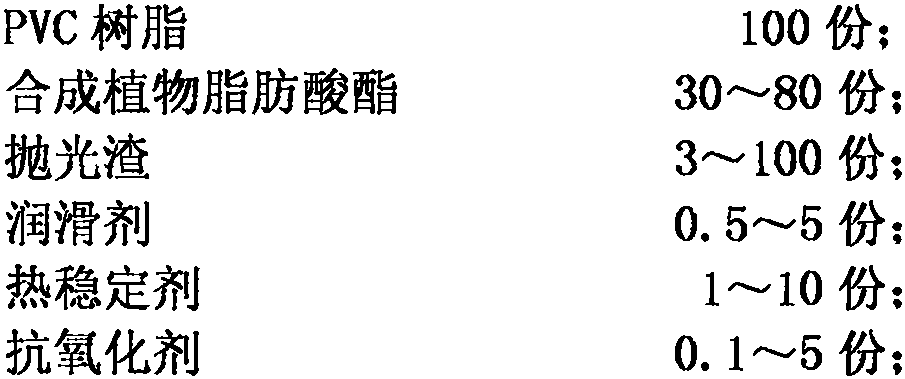

[0033] The various raw material formulations that make up the flame-retardant and anti-static PVC wire and cable material are weighed according to the following mass fractions respectively, and set aside.

[0034]

[0035] Put the PVC resin powder into the high-speed mixer, stir at high speed for 7 minutes to dry the water; then add synthetic vegetable fatty acid ester, stir at high speed for 5-10 minutes; then add the rest of the raw materials, stir at low speed for 3 minutes; In the mixer, stir for another 10 minutes, discharge the material after cooling, and prepare the flame-retardant and anti-static PVC wire and cable compound.

[0036] 2. Extrusion:

[0037] Put the mixture into the twin-screw extruder, and extrude it into a round rubber strip through the head die of the extruder. The temperature of each zone of the extruder is: zone 1 / 145°C, zone 2 / 160°C, zone 3 / 170°C , zone 4 / 175°C, handpiece / 180°C.

[0038] 3. Pelletizing:

[0039] The rubber...

Embodiment approach 2

[0042] 1. Mixture:

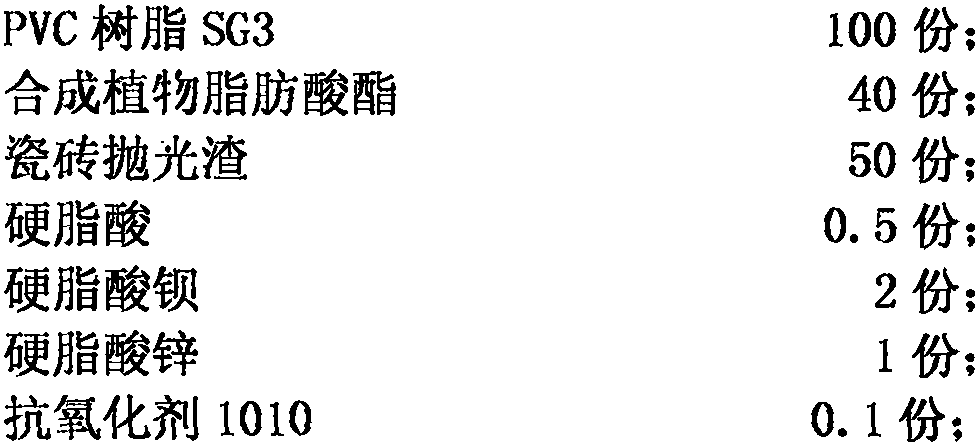

[0043] The various raw material formulations that make up the flame-retardant and anti-static PVC wire and cable material are weighed according to the following mass fractions respectively, and set aside.

[0044]

[0045] Put the PVC resin powder into the high-speed mixer, stir at high speed for 7 minutes to dry the water; then add synthetic vegetable fatty acid ester, stir at high speed for 5-10 minutes; then add the rest of the raw materials, stir at low speed for 3 minutes; In the mixer, stir for another 10 minutes, discharge the material after cooling, and prepare the flame-retardant and anti-static PVC wire and cable compound.

[0046] 2. Extrusion:

[0047] Put the mixture into the single-screw extruder, and extrude it into a round rubber strip through the head die of the extruder. The temperature of each zone of the extruder is: zone 1 / 140°C, zone 2 / 155°C, zone 3 / 165°C , Head / 175°C.

[0048] 3. Pelletizing:

[0049] The rubber strip extruded...

Embodiment approach 3

[0052] 1. Mixture:

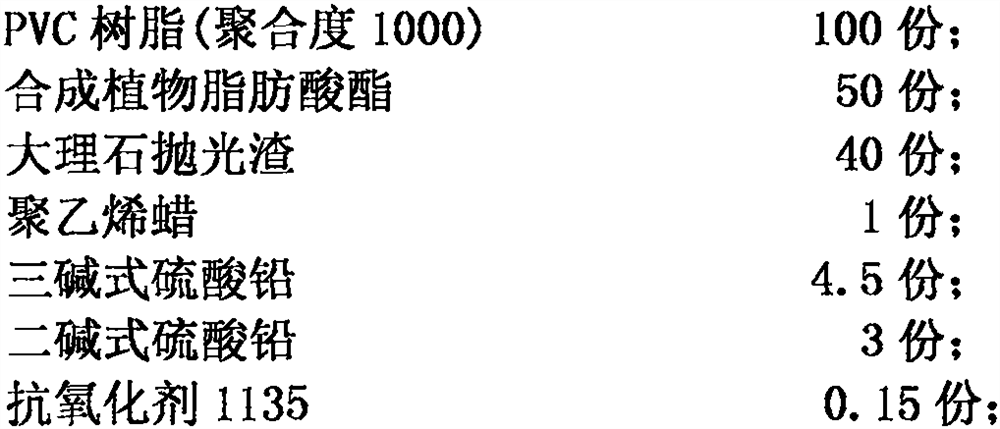

[0053] The various raw material formulas that make up the flame-retardant and antistatic PVC cable material are weighed according to the following mass fractions respectively, and set aside.

[0054]

[0055] Put the PVC resin powder into the high-speed mixer, stir at high speed for 7 minutes to dry the water; then add synthetic vegetable fatty acid ester, stir at high speed for 5-10 minutes; then add the rest of the raw materials, stir at low speed for 3 minutes; In the mixer, stir for another 10 minutes, discharge the material after cooling, and prepare the flame-retardant and anti-static PVC wire and cable compound.

[0056] 2. Extrusion:

[0057] Put the mixture into the single-screw extruder, and extrude it into a round rubber strip through the head die of the extruder. The temperature of each zone of the extruder is: zone 1 / 140°C, zone 2 / 155°C, zone 3 / 165°C , Head / 175°C.

[0058] 3. Pelletizing:

[0059] The rubber strips extruded by the extru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com