Odorless water-based coating produced from slag micro-powder, and preparation method thereof

A water-based paint and micropowder technology, applied in antifouling/underwater paints, biocide-containing paints, coatings, etc., can solve problems such as hazards and dust pollution, achieve extremely low VOC, reduce VOC emissions, and improve environmental protection performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

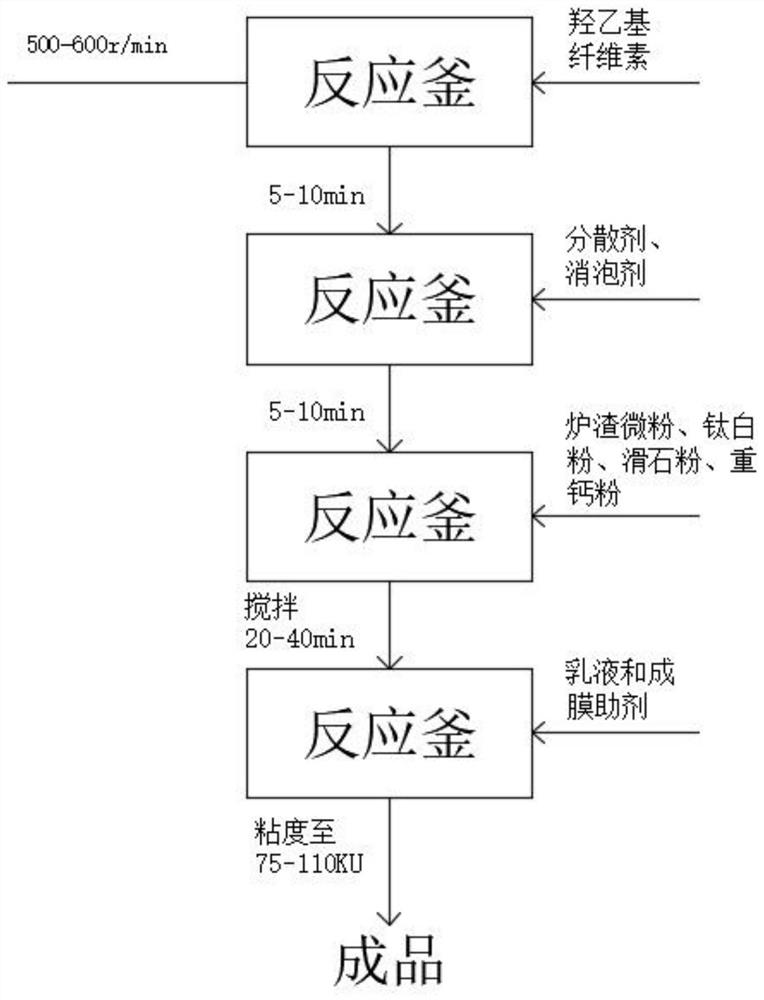

[0037]A preparation equipment for clean-odor water-based paint produced by slag micropowder, including a reaction kettle, adding water into the reaction kettle, adjusting the rotation speed of the reaction kettle to 500-600r / min, slowly adding hydroxyethyl cellulose to disperse for 5-10 minutes while stirring After 5-10 minutes, add additives such as dispersant and defoamer, stir for 5-10 minutes, then add slag powder, titanium dioxide, talcum powder, heavy calcium powder, etc. into the solution, stir After 20-40 minutes, the fineness of the paint will drop below 50 μm. If the fineness is too high, it needs to be ground to below 50 μm before proceeding to the next step. Reduce the speed to 500 rpm, add emulsion, defoamer, etc., and pass through the odor-cleaning emulsion Add a certain amount of pigment to adjust the system to the required color, and use alkali swelling or polyurethane thickener to adjust the viscosity of the system to 75-110KU.

[0038] Slag micropowder is a n...

Embodiment 2

[0050] A method for preparing a deodorizing water-based paint produced by using slag micropowder, the components and weight percentages of each raw material: 20-30% of water, 10-30% of slag micropowder, 0-10% of titanium dioxide, 0-20% of heavy calcium powder, Kaolin 0-15%, heavy calcium powder 0-15%, talcum powder 0-5%, emulsion 10-50%, additives 3-8%.

[0051] Proceed as follows:

[0052] S1. According to the above ratio, weigh each raw material component, each weight percentage is: water 20-30%, slag fine powder 10-30%, titanium dioxide 0-10%, heavy calcium powder 0-20%, kaolin 0- 15%, heavy calcium powder 0-15%, talc powder 0-5%, emulsion 10-50%, additives 3-8%;

[0053] S2. Add the powder thickener hydroxyethyl cellulose into water, and stir for 10 minutes until a uniform solution A is obtained;

[0054] S3, adding a dispersant and an antifoaming agent to the obtained solution A, and stirring for 10 minutes to obtain a solution B evenly;

[0055] S4. In the solution B ...

Embodiment 3

[0059] A pure odor interior wall paint, the weight of each raw material is: water slag superfine powder is 200kg, rutile titanium dioxide is 100kg, rutile titanium dioxide is 25kg, kaolin is 100kg, talcum powder is 50kg, hydroxyethyl cellulose is 2kg, 4kg of defoamer, 8kg of dispersant, 16kg of film-forming aid, 10kg of freeze-thaw stabilizer, 200kg of emulsion, 5kg of dispersant, 280kg of deionized water, 5kg of alkali swelling thickener, the total mass is about 1t.

[0060] (1) according to above-mentioned proportioning, take each raw material component;

[0061] (2) Add the powder thickener into water, stir for 10 minutes to obtain solution A evenly;

[0062] (3) Add dispersant and defoamer to the obtained solution A, and stir to obtain solution B;

[0063] (4) Slowly add solid powder such as slag micropowder, titanium dioxide, talc powder, mica powder, etc. to the obtained solution B under stirring to avoid agglomeration. If the particle size is greater than 50 μm, grindi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com