10-gigabit Ethernet cable and preparation method thereof

A technology of Ethernet and wire cores, applied in the field of Ethernet cables, can solve the problems of overweight cables, insufficient transmission speed of aerospace data bus, insufficient bandwidth, etc., and achieve the effects of low loss, excellent shielding performance, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention also provides a preparation method of the above-mentioned 10 Gigabit Ethernet cable, the preparation method comprising:

[0030] 1) Twisting silver-plated copper wires to form a core wire unit 1, wrapping polytetrafluoroethylene on the outside of the wire core to obtain a wire core, and twisting multiple wire cores into a multi-core star-stranded wire;

[0031] 2) Wrap the polyimide composite aluminum strip around the outside of the multi-core star-stranded wire to form the first shielding layer 3;

[0032] 3) braiding silver-plated copper wires outside the first shielding layer 3 to form a second shielding layer 4;

[0033] 4) Wrap the cross-linked ethylene-tetrafluoroethylene copolymer on the outside of the second shielding layer 4 to form a sheath 5 .

[0034] In the above preparation method, the coating conditions in step 1) can be selected in a wide range. In order to further improve the signal transmission capability and transmission quality...

Embodiment 1

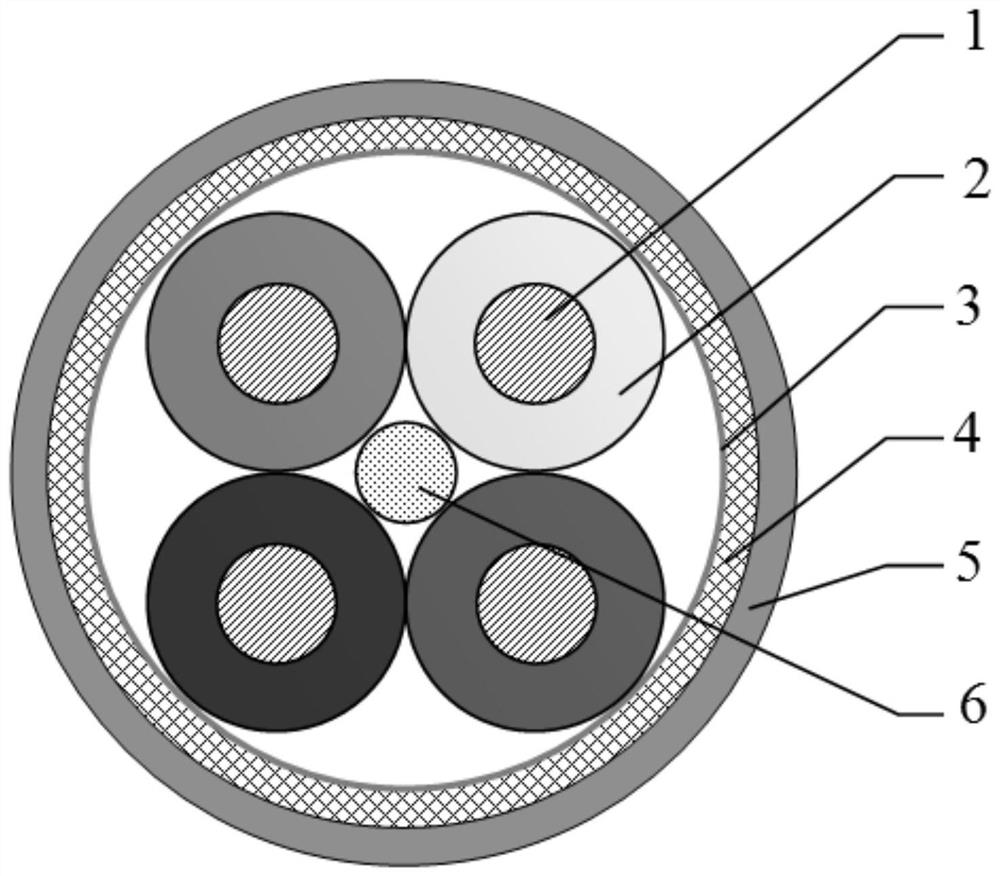

[0039] 1) Twisted 19 strands of silver-plated copper wires with a diameter of 0.102mm to form the core wire unit 1, extruded polytetrafluoroethylene on the outside of the core wire, and then sintered (at a temperature of 250°C and a vacuum degree of 110KPa, the traction speed is 80m / min) to form an insulating layer 2 (thickness is 0.15mm) to obtain the wire core, and 4 said wire cores are star-stranded in a high-speed star twisting machine (the traction speed is 6m / min, and the cabling The pitch is 37mm) to obtain a multi-core star stranded wire;

[0040] 2) Wrap the polyimide composite aluminum strip around the multi-core star stranded wire and a polytetrafluoroethylene filled core 6 to form the first shielding layer 3 (thickness is 0.15mm);

[0041] 3) braiding silver-plated copper wires on the outside of the first shielding layer 3 to form a second shielding layer 4 (thickness is 0.40mm);

[0042] 4) Extrude the cross-linked ethylene-tetrafluoroethylene copolymer on the ou...

Embodiment 2

[0044] 1) Twisting 19 strands of silver-plated copper wires with a diameter of 0.102mm to form a core wire unit 1, extruding polytetrafluoroethylene on the outside of the core wire, and then sintering (at a temperature of 230°C and a vacuum degree of 130KPa, the traction speed is 60m / min) to form an insulating layer 2 (thickness is 0.18mm) to obtain the wire core, and 6 said wire cores are star-stranded in a high-speed star twisting machine (the traction speed is 3m / min, and the cabling The pitch is 32mm) to obtain a multi-core star stranded wire;

[0045] 2) Wrap the polyimide composite aluminum strip around the multi-core star stranded wire and a polytetrafluoroethylene filled core 6 to form a first shielding layer 3 (thickness is 0.16mm);

[0046] 3) braiding silver-plated copper wires on the outside of the first shielding layer 3 to form a second shielding layer 4 (thickness is 0.45mm);

[0047] 4) Extrude the cross-linked ethylene-tetrafluoroethylene copolymer on the outsi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com