Back surface structure of IGBT device, preparation method of back surface structure, and IGBT device

A backside structure and device technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of current concentration and turn-off failure at the main junction at the edge of the active region, and achieve excellent breakdown characteristics and small Effects of leakage current and high breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

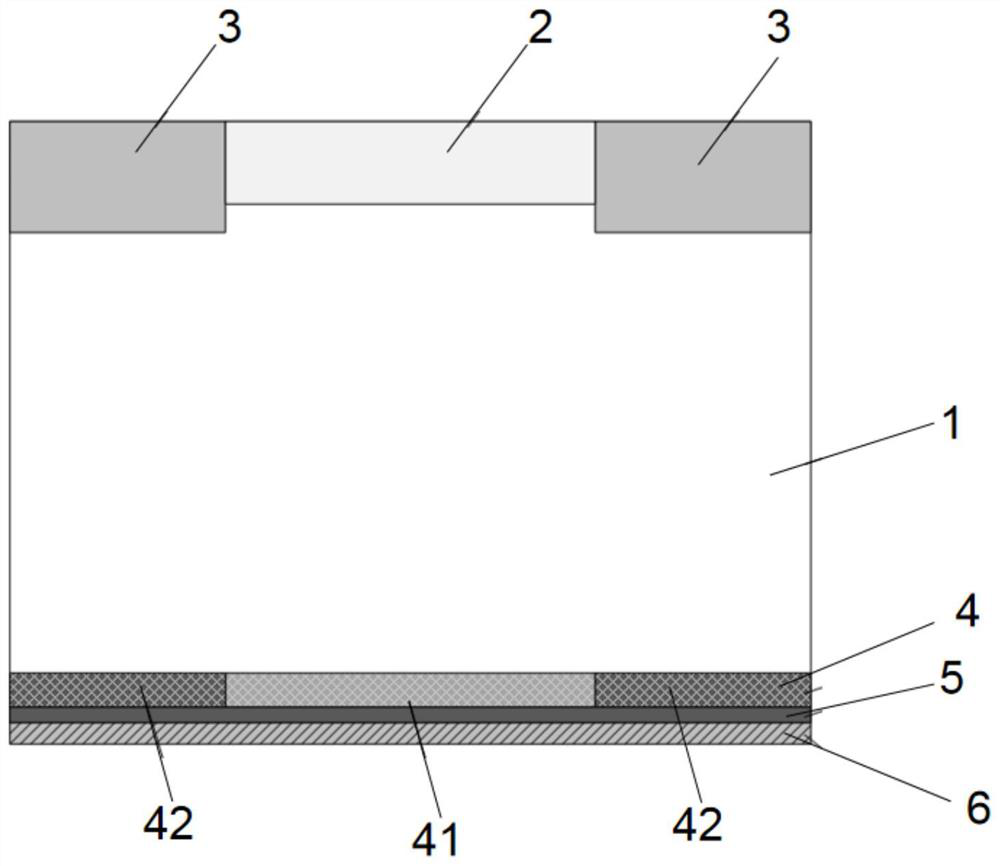

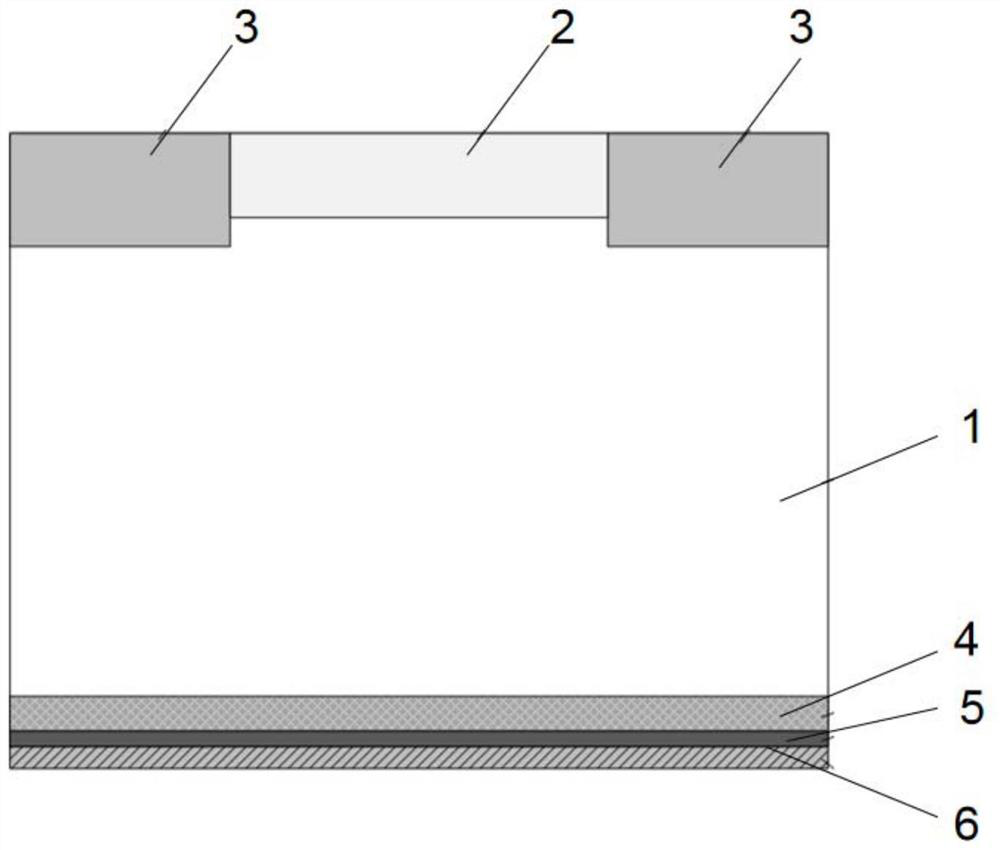

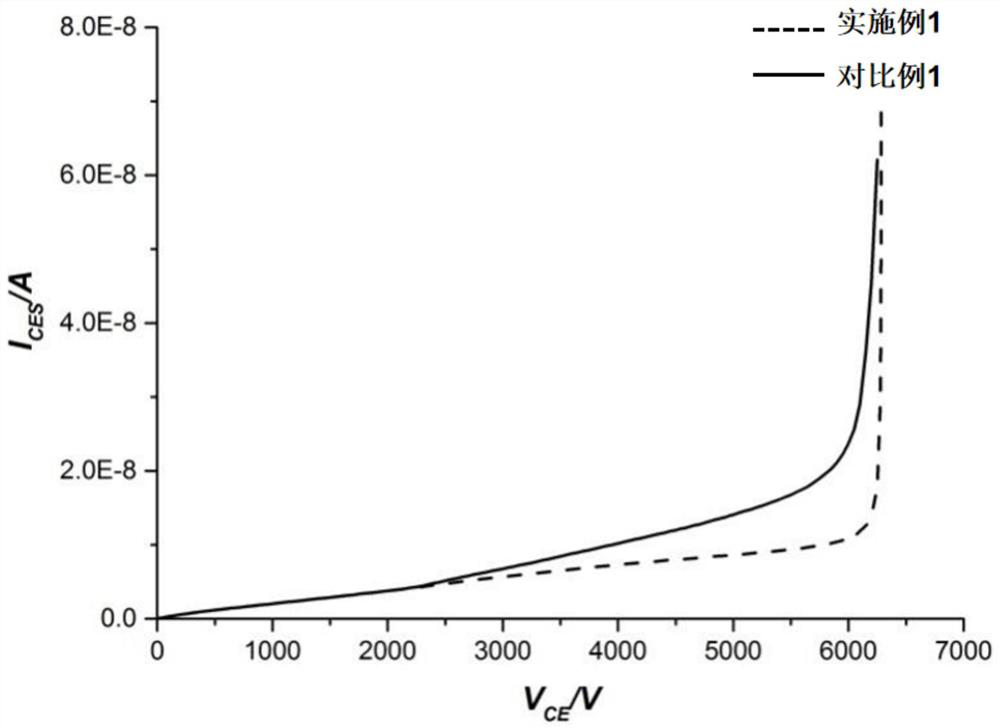

[0036] Such as figure 1 As shown, the present embodiment provides a backside structure of an IGBT device, including a buffer layer 4, and the buffer layer 4 includes a first activation efficiency buffer 41 corresponding to the active region 2 of the IGBT device and a first activation efficiency buffer region 41 corresponding to the terminal region 3 of the IGBT device. The second activation efficiency buffer 42, wherein the activation rate of the first activation efficiency buffer 41 is smaller than the activation efficiency of the second activation efficiency buffer 42.

[0037] Due to the effective doping concentration (N DSPT ) and the current gain of the parasitic transistor PNP of the IGBT device (β PNP ) is inversely proportional to the hole injection efficiency of the terminal region 3 of the IGBT device as the current gain (β PNP ) increases, that is, as the effective doping concentration (N DSPT ) increases, the hole injection efficiency gradually decreases. By se...

Embodiment 2

[0042] This embodiment provides a method for preparing the back structure of an IGBT device, and the IGBT device provided in Embodiment 1 can be obtained, which specifically includes the following steps:

[0043] (1) After completing the preparation of the front structure of the IGBT device, the first ion implantation is carried out to the back side of the wafer to form a buffer layer;

[0044] (2) Carry out the first laser annealing to the buffer layer, wherein, the region corresponding to the active region of the IGBT device in the buffer layer forms the first activation efficiency buffer zone, and the region corresponding to the terminal region of the IGBT device in the buffer layer forms the second Activate efficiency buffer. Specifically, the dose of the first ion implantation is 5E13cm -2 -1E14cm -2 , the implanted element is phosphorus; the formation condition of the first activation efficiency buffer zone is that the laser wavelength is 510-550nm, and the laser energ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com