Automatic and efficient corn stalk crusher

A corn stalk and pulverizer technology, which is applied to agricultural machinery and implements, cutting equipment, applications, etc., can solve the problems of unsatisfactory stalk pulverization, increase farmers' work intensity, and low feeding effect, so as to improve resource utilization and improve The effect of labor productivity, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

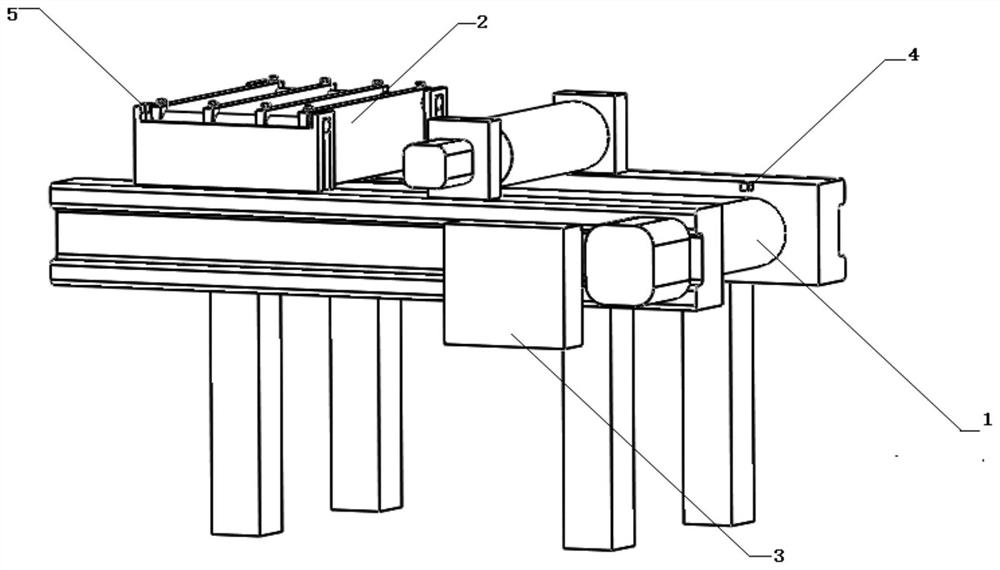

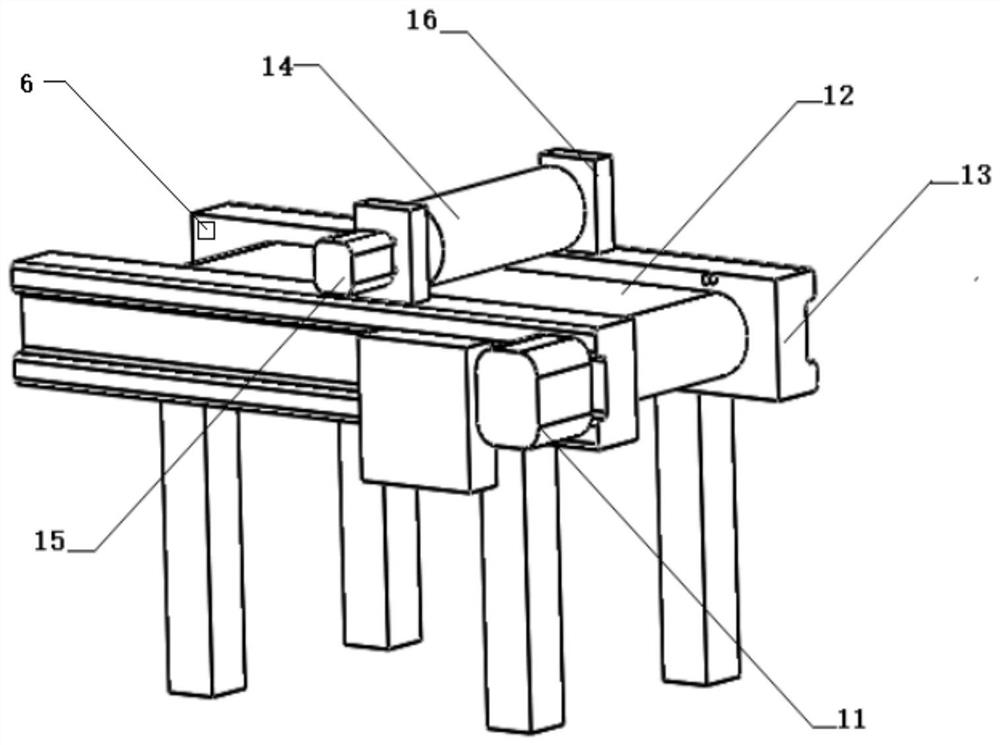

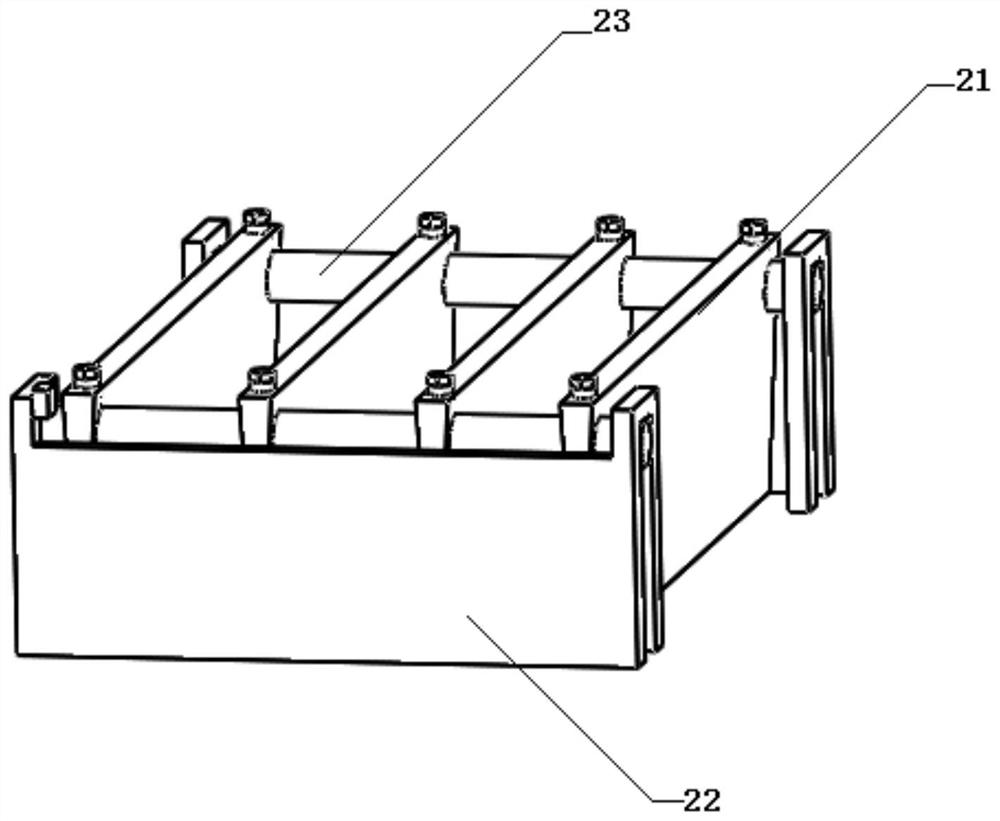

[0020] When performing straw crushing operations, when the straw is placed on the conveyor belt (12), a signal is sent to the controller through the detection of the photoelectric sensor 1 (4), and the controller drives the stepper motor (11) and the motor (15) after receiving the signal Rotate, the stepper motor (11) rotates forward to transport the straw, and the motor (15) drives the roller (14) to rotate and compress the straw on the conveyor belt (12); when the straw reaches the designated position, the photoelectric sensor 2 (6) can The straw is detected and a signal is sent to the controller, the stepping motor (11) and the motor (15) stop rotating, at the same time, the controller drives the hydraulic actuator to move to drive the guillotine (21) to cut the straw, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com