Capillary crystalline backwater coating and preparation method thereof

A technology of osmotic crystallization and backwater, applied in the field of construction, can solve the problem that the second impermeability pressure index needs to be improved, and achieve the effect of outstanding performance and simple and easy-to-control process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

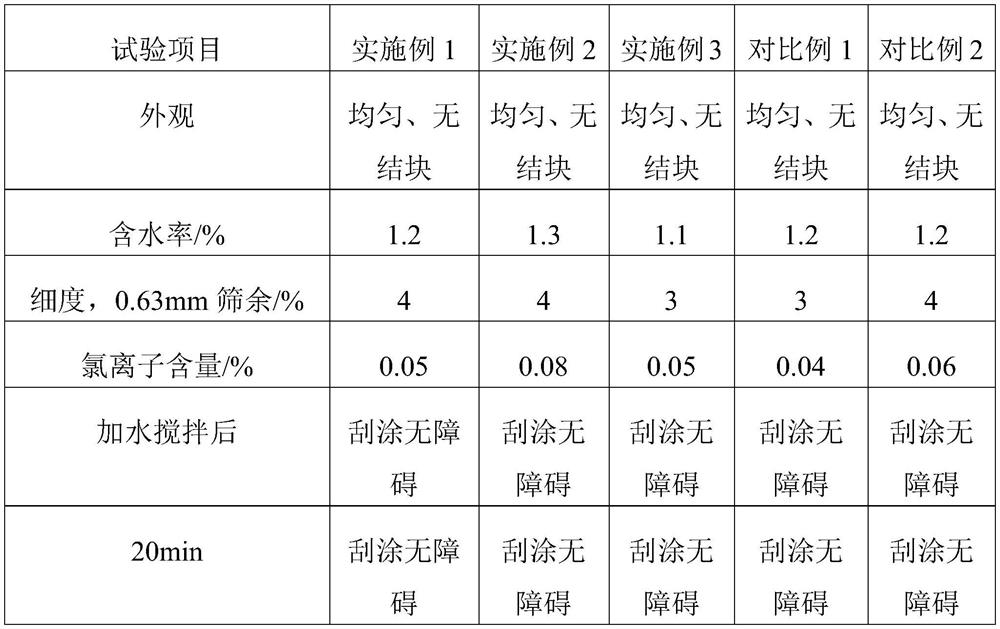

Embodiment 1

[0025] The present embodiment provides a kind of preparation method of osmotic crystalline type backwater paint, comprises the steps:

[0026] (1) Divide 420kg Portland cement into two parts to obtain 315kg Portland cement a and 105kg Portland cement b; divide 390kg quartz sand with a particle size of 80 mesh into two parts to obtain 195kg quartz sand a and 195kg quartz sand b ;

[0027] (2) Mix 315kg of Portland cement a with 195kg of quartz sand a, then add 50kg of latex powder, and stir evenly for 30min under the condition of 30r / min to obtain mixture a;

[0028] (3) Add 8kg sodium silicate, 8kg borax, 1.5kg powder defoamer, 1.5kg hydroxypropyl methylcellulose, 4kg polyvinyl alcohol, 0.8kg water reducer and 0.6kg water-repellent powder in sequence in mixture a, Stir evenly for 50 min under the condition of 50 r / min to obtain mixture b;

[0029] (4) Add 105kg of Portland cement b, 195kg of quartz sand b and 70kg of quartz powder with a particle size of 180 mesh to the mixt...

Embodiment 2

[0031] The present embodiment provides a kind of preparation method of osmotic crystalline type backwater paint, comprises the steps:

[0032] (1) Divide 440kg of Portland cement into two parts to obtain 325kg of Portland cement a and 115kg of Portland cement b; divide 410kg of quartz sand with a particle size of 120 mesh into two parts to obtain 205kg of quartz sand a and 205kg of quartz sand b ;

[0033] (2) Mix 325kg of Portland cement a with 205kg of quartz sand a, then add 70kg of latex powder, and stir evenly for 40min under the condition of 40r / min to obtain mixture a;

[0034] (3) Add 12kg sodium silicate, 12kg borax, 2.5kg powder defoamer, 2.5kg hydroxypropyl methylcellulose, 4.5kg polyvinyl alcohol, 1.2kg water reducing agent and 1kg water-repellent powder to mixture a successively, Stir evenly for 60 minutes under the condition of 60r / min to obtain mixture b;

[0035] (4) Add 115kg of Portland cement b, 205kg of quartz sand b and 90kg of quartz powder with a parti...

Embodiment 3

[0037] The present embodiment provides a kind of preparation method of osmotic crystalline type backwater paint, comprises the steps:

[0038] (1) Divide 430kg of Portland cement into two parts to obtain 310kg of Portland cement a and 120kg of Portland cement b; divide 400kg of quartz sand with a particle size of 100 mesh into two parts to obtain 200kg of quartz sand a and 200kg of quartz sand b ;

[0039] (2) Mix 310kg of Portland cement a with 200kg of quartz sand a, then add 60kg of latex powder, and stir evenly for 35min under the condition of 35r / min to obtain mixture a;

[0040] (3) Add 10kg sodium silicate, 10kg borax, 2kg powder defoamer, 2kg hydroxypropyl methylcellulose, 4.2kg polyvinyl alcohol, 1kg water reducer and 0.8kg hydrophobic powder to the mixture a in sequence, at 55r Stir evenly for 55min under the condition of / min to obtain mixture b;

[0041] (4) Add 120kg of Portland cement b, 200kg of quartz sand b and 80kg of quartz powder with a particle size of 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com