A pyrolysis gasification combustion system and process for highly viscous organic waste

A technology of pyrolysis and gasification of organic waste, applied in the direction of gasification process, combustion type, combustion method, etc., can solve the problem of low-cost and effective disposal of direct combustion or co-combustion, rapid increase of operating pressure above the air chamber, Issues affecting the safe and stable operation of the system, to achieve the effect of ensuring safe and stable operation, universal applicability, and easy promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

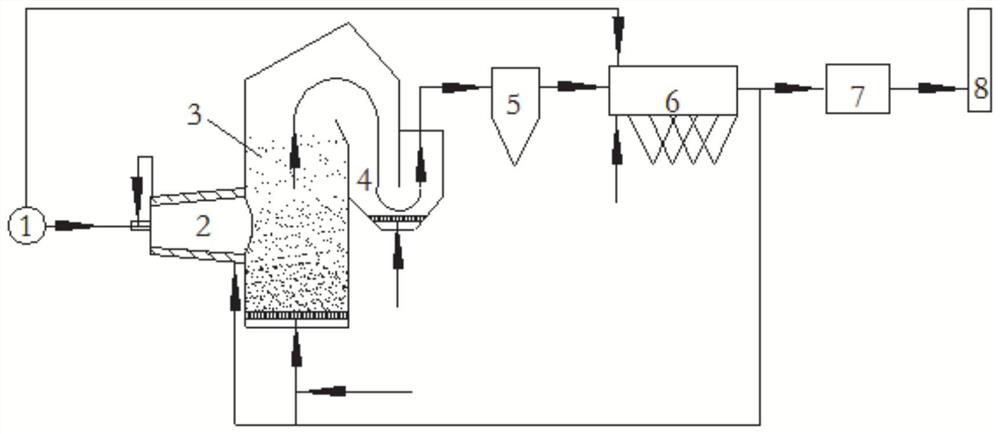

[0063] Such as figure 1 As shown, a pyrolysis gasification combustion system for highly viscous organic waste, including a mixing tank 1, a pyrolysis reactor 2, a gasification reactor 3, an ash combustion chamber 4, a high-temperature cyclone dust collector 5, Gas boiler 6, flue gas purification device 7, chimney 8 and associated pipelines, pumps and fans.

[0064] The highly viscous organic wastes produced in the production process of traditional Chinese medicine such as sediment residue and dry distillation liquid are stirred and mixed evenly in the mixing tank 1, and the mixing tank 1 is equipped with a heating device to reduce the viscosity of the material to meet the requirements of pumping and atomization; the mixing tank 1 The negative pressure is used to collect organic waste gas such as ethanol and other organic waste gases that are mixed and stirred by the materials and volatilized by heating, and passed into the gas boiler 6 for combustion.

[0065] Settled slag an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com