Oil gas recovery comprehensive tester for gas station

A comprehensive tester and gas station technology, which is applied to the analysis of gas mixtures, instruments, measuring devices, etc., can solve the problems of inportability and slow detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

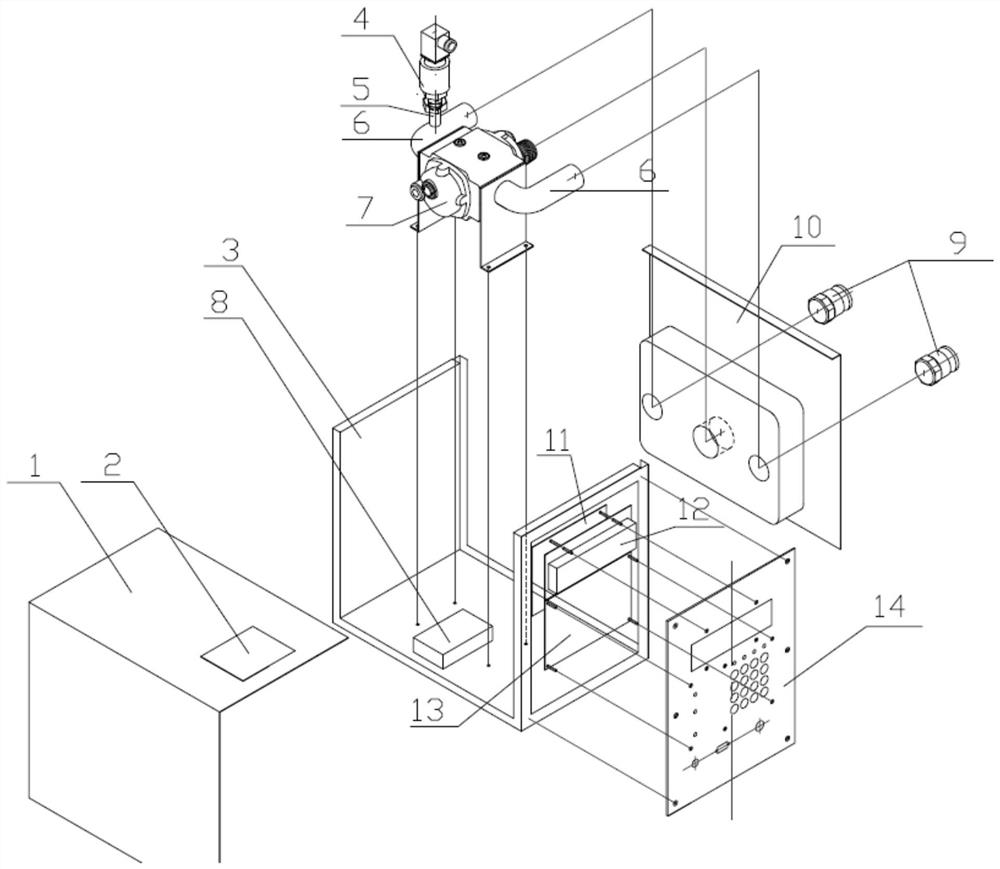

[0020] A gas station oil gas recovery comprehensive tester, such as figure 1 As shown, including the chassis base, front panel, battery pack, keyboard circuit board, main control board, LCD display, pressure sensor, flow sensor, the pressure sensor is connected to the gas pipeline of the flow meter sensor interface through the pressure sensor interface, and the flow rate The sensors are connected in series into the gas pipeline of the flowmeter sensor interface, and the connected gas pipeline is seated on the bottom plate of the battery pack of the instrument through the bracket; the instrument circuit board, instrument display circuit board, and instrument key circuit board are installed on the front panel of the chassis frame Paste the nameplate of the instrument on the upper cover, pass the air outlet of the air pipeline of the flowmeter sensor interface through the reserved opening on the right cover, and install the gas outlet at the air outlet of the air pipeline of the f...

Embodiment 2

[0037] (1) Airtightness and liquid resistance detection

[0038] Let's take the detected data of Jiujiang Yunshan gas station as an example:

[0039] Stop before the start of the test, all gasoline tankers are not allowed to refuel, and the diesel engine can work normally.

[0040] Close the return air pipeline valves under all gasoline dispensers, select the dispenser farthest from the oil tank line as the leak detection dispenser, and connect the pipeline with copper adapters to the detection port under the dispenser to ensure that the upper Tight airtight, the other end of the pipeline is connected to the outlet port of the oil vapor recovery tester.

[0041] Then connect the static grounding wire of the steel cylinder, and connect the other end of the copper braided static grounding wire to the static electricity removal sheet of the fuel dispenser to eliminate static electricity.

[0042] Connect the nitrogen pipeline, and connect the other end of the nitrogen pipeline ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap