A method of recovering olefins in a solution polymerisation process

A solution and polymer technology, applied in separation methods, chemical instruments and methods, chemical liquid solidification, etc., can solve problems such as difficult control of polymer density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

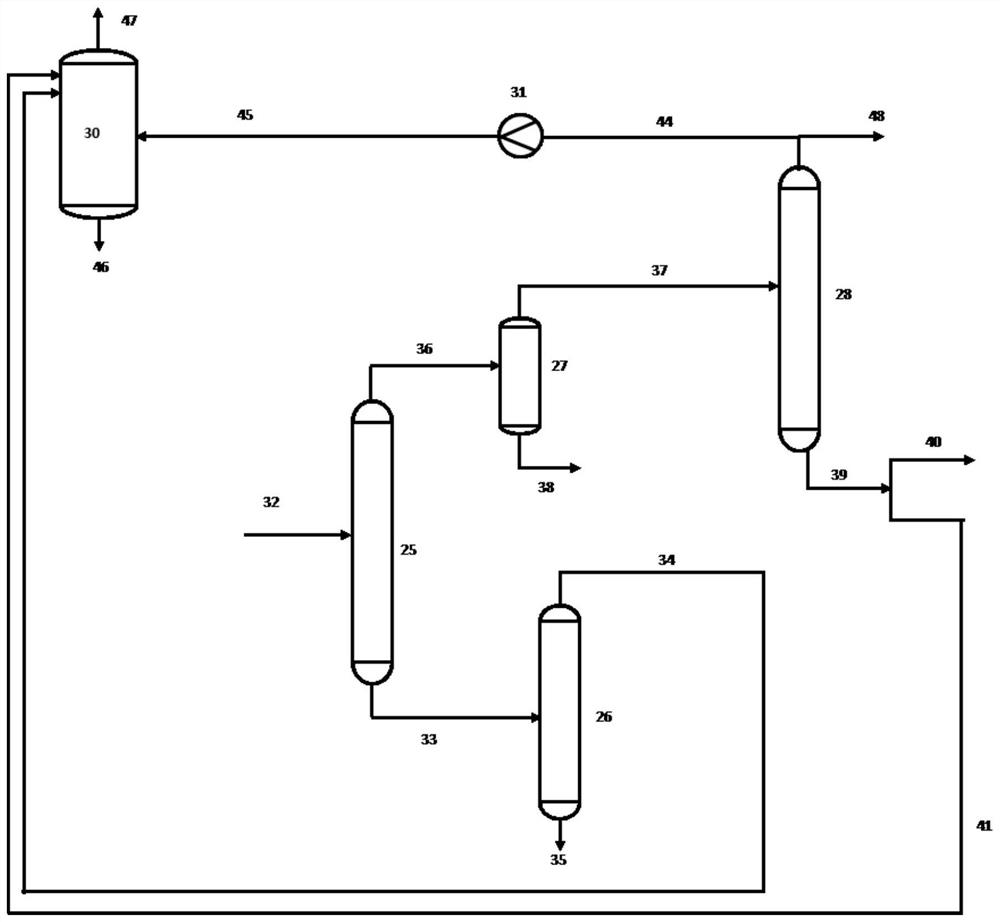

[0066] Computer simulations were performed using Aspen 8.8 computer software. In the simulation, ethylene and 1-hexene were polymerized in n-octane in a polymerization reactor. A product stream is withdrawn from the polymerization reactor. The product stream undergoes three subsequent flash steps. A portion of the vapor stream from each flash step is directed to the first fractionator. The overhead stream from the first fractionator is sent to the second fractionator. The overhead stream from the second fractionator is sent to the third fractionator. In an embodiment of the invention, a portion of the bottoms stream from the third fractionator is recovered as a sweep stream from line 40 . In the comparative example, a portion of the overhead stream from the first fractionator was recovered as a sweep stream from line 36 . Table 1 compares the purge flow at different locations.

[0067] Table 1

[0068] purge flow CE IE Total mass flow(kg / h) 176.8 17...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com