Laser wafer lift-off device and laser wafer lift-off method

A laser lift-off and wafer technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of low work efficiency, reduce the controllability of the processing process, and increase the processing cost, so as to improve quality and efficiency, Eliminate laser processing defects and achieve the effect of secondary processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

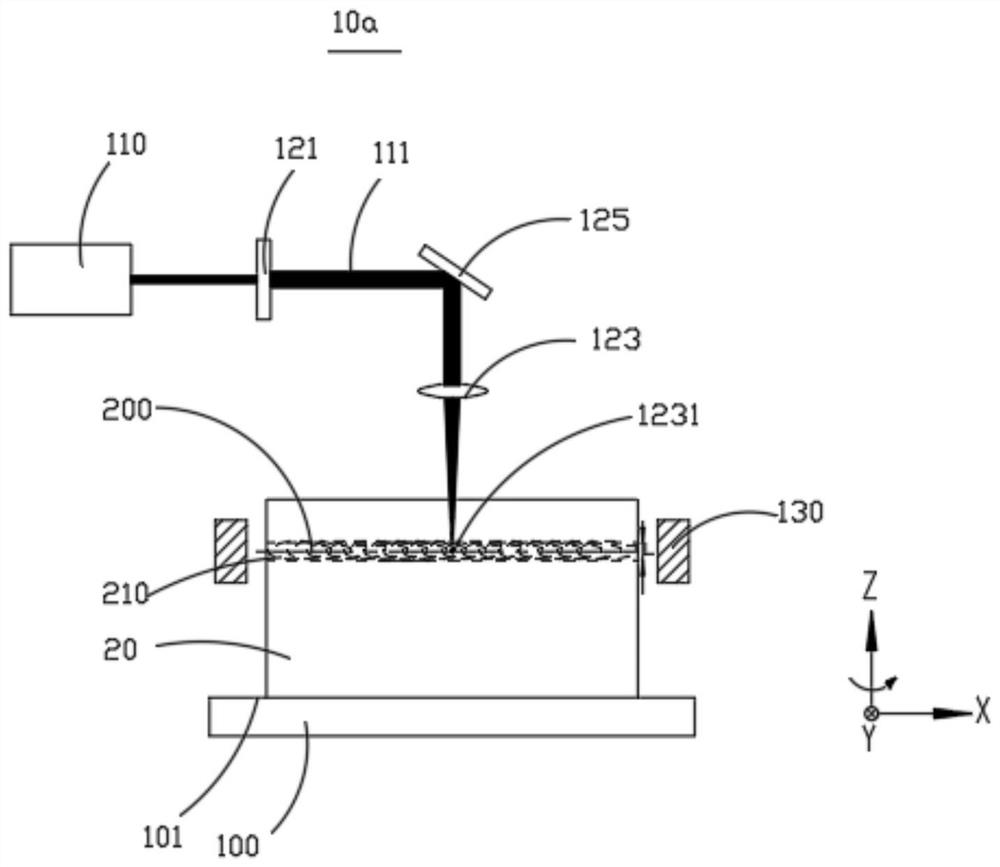

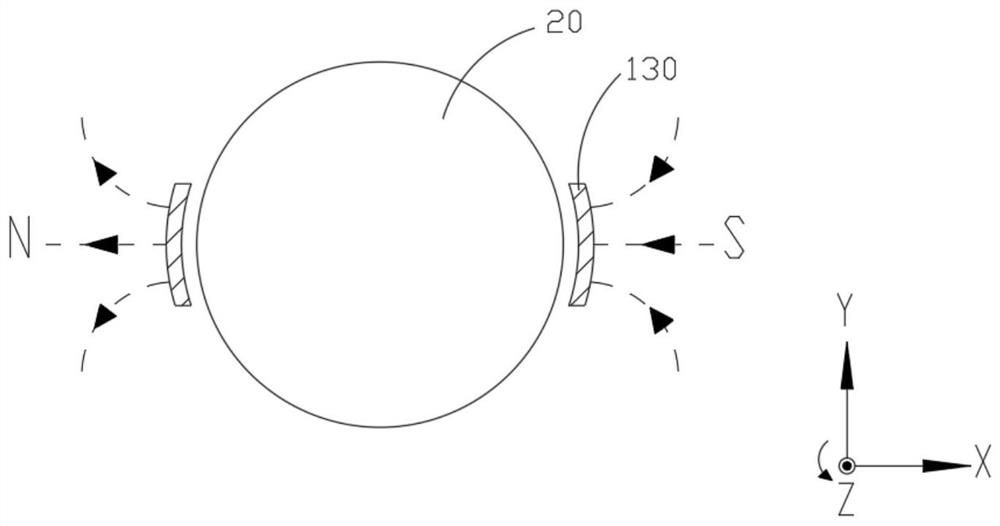

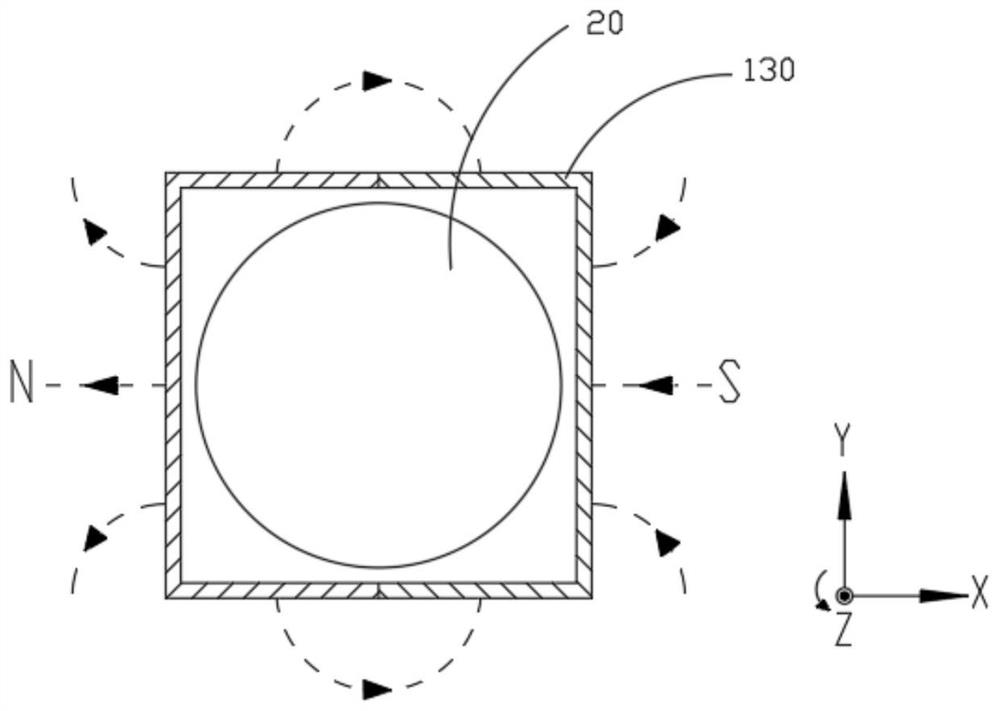

[0043] see figure 1 , a laser lift-off wafer apparatus 10a, which includes: an installation platform 100, a laser emitter 110, a condenser lens assembly, a magnet, and a control system (not shown).

[0044] The installation platform 100 has a bearing surface 101 parallel to the horizontal plane. The bearing surface 101 is used to install and fix the crystal ingot 20 to ensure the stability of the crystal ingot 20 during cutting.

[0045] The laser emitter 110 is used to emit a laser beam, and the laser emitter 110 is specifically, for example, a femtosecond laser, etc., which is not limited herein.

[0046] The focusing lens assembly is used to receive the laser beam 111 emitted by the laser emitter 110 and focus the received laser beam 111 in the crystal ingot 20 to induce the crystal ingot 20 to generate plasma.

[0047] Wherein, the condenser lens assembly includes a beam expander 121 and a focus lens 123, the beam expander 121 receives the laser beam 111 sent by the laser t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com