Green brick discharging process for sintered bricks

A technology of sintered bricks and adobes, which is applied in the field of building materials, can solve the problems of high labor intensity, low efficiency of adobe discharge, and easy fatigue of operators, and achieve the effect of reducing labor intensity and improving discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0043] A brick adobe 5 discharging process for sintered bricks disclosed by the present invention comprises;

[0044] S1: the adobe 5 is conveyed, and the adobe 5 cut by the automatic strip cutting machine is conveyed and discharged through the first conveyor belt 1;

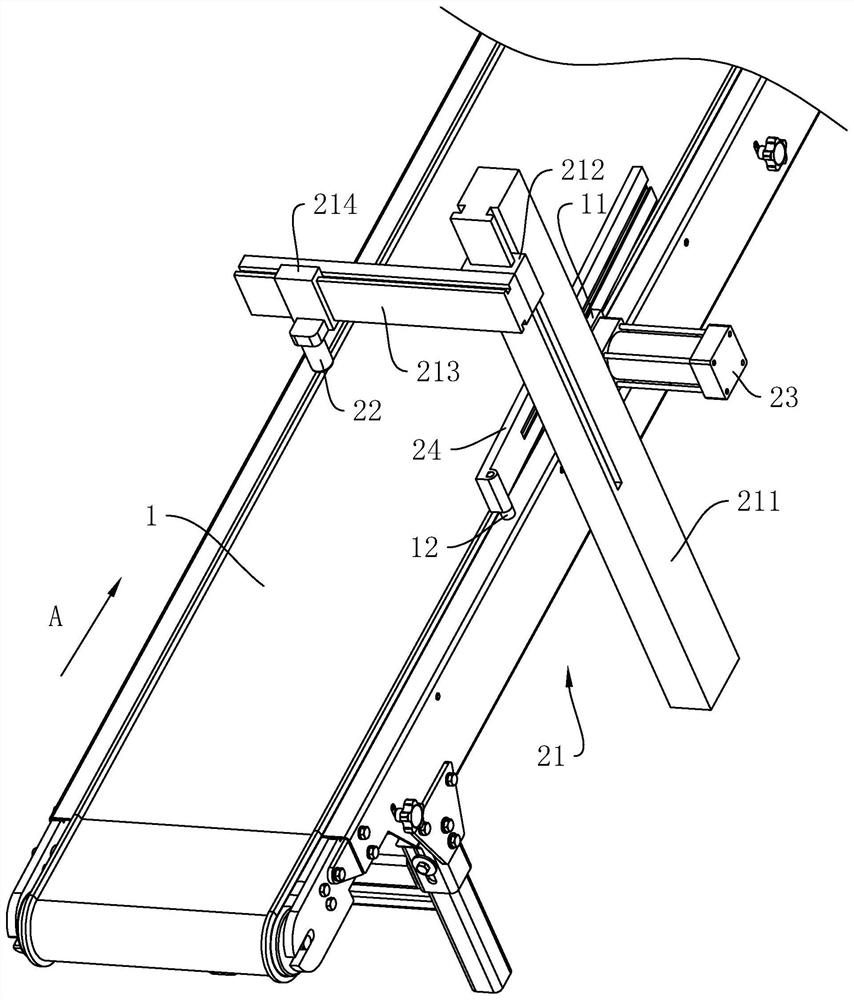

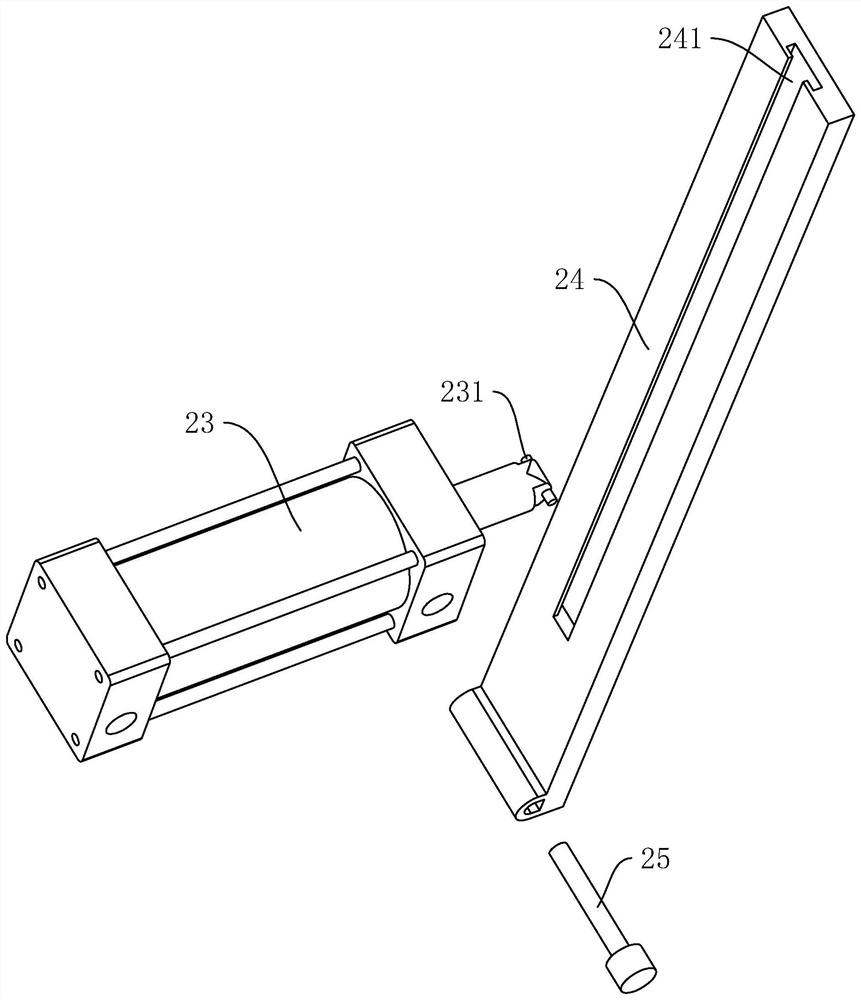

[0045] S2: Rejecting the waste blanks, the waste blanks on the first conveyor belt 1 are removed by the waste blank removing mechanism 2, and the recovery conveyor belt 4 picks up the waste blanks and transports the waste blanks to the raw material place for recycling;

[0046] S3: Clamp the adobe 5 and stack it. The adobe 5 is picked up by the palletizing mechanism 3 and the adobe 5 is removed from the first conveyor belt 1 for stacking.

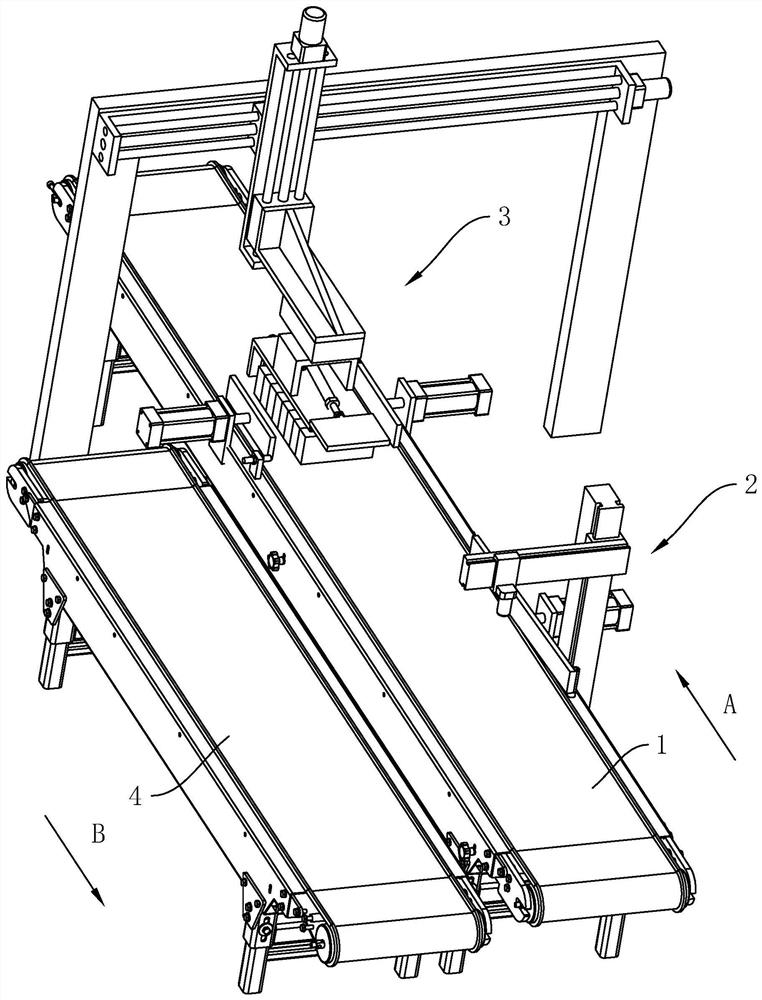

[0047] refer to figure 1 , the first conveyor belt 1 transports adobes 5 along the direction of the arrow A, and the adobes 5 pass through the waste adobe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap