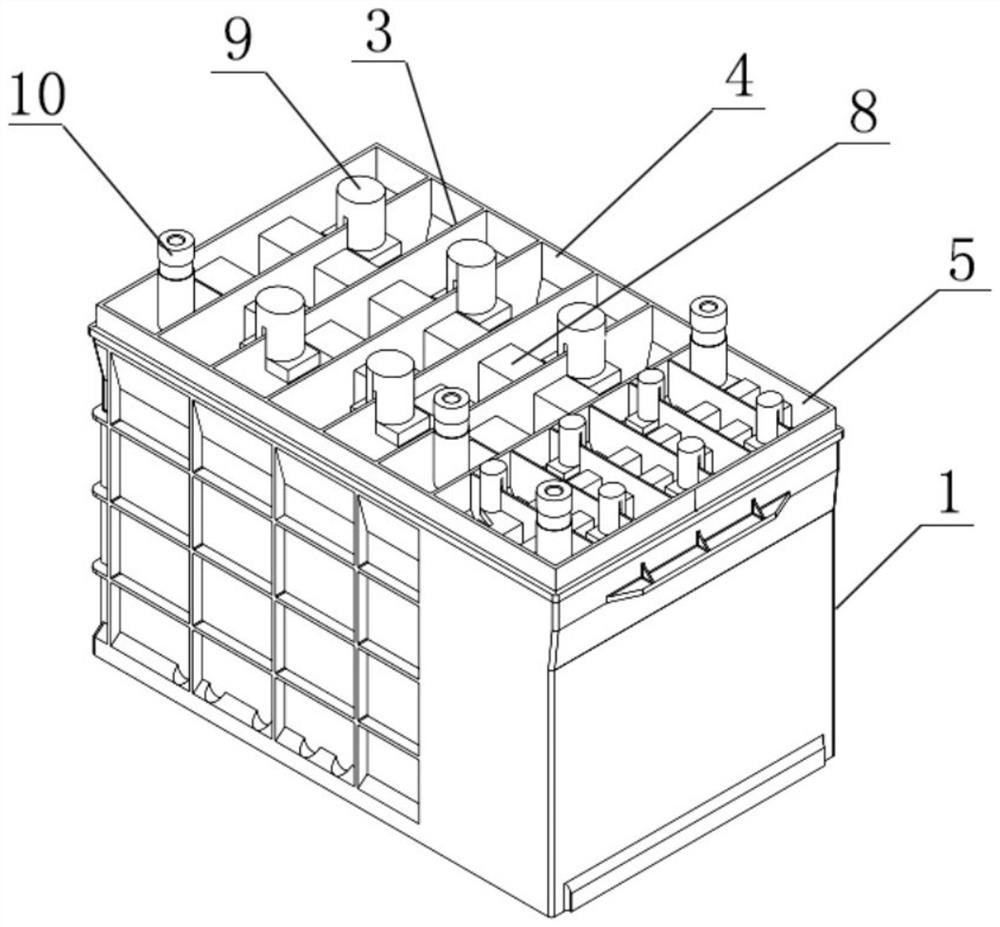

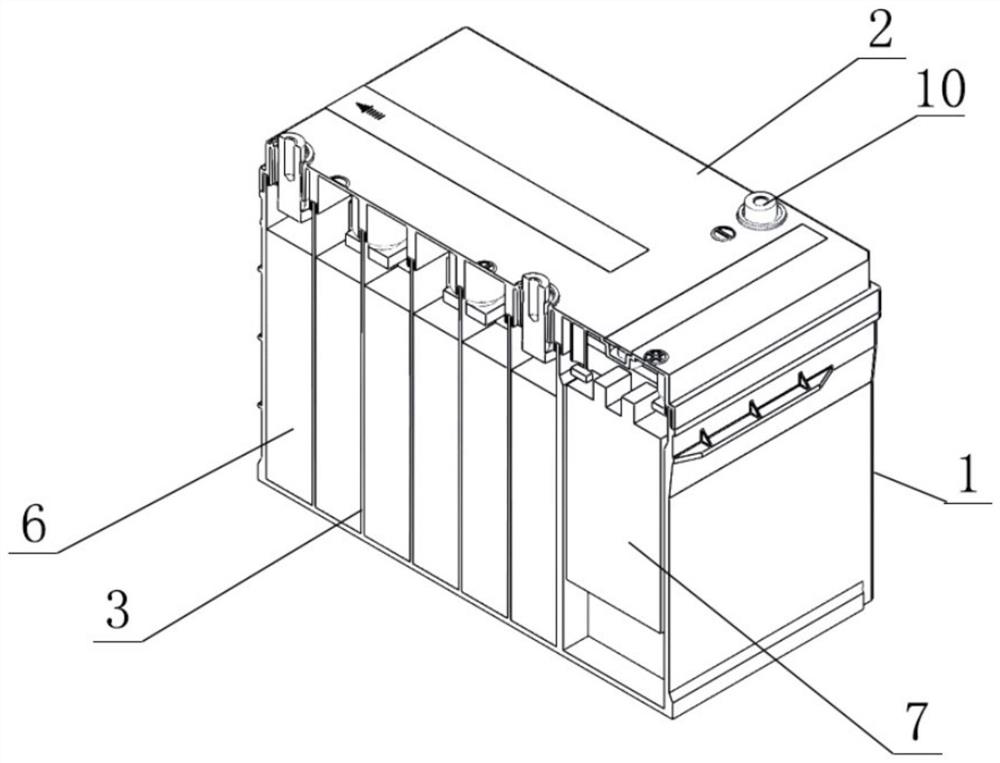

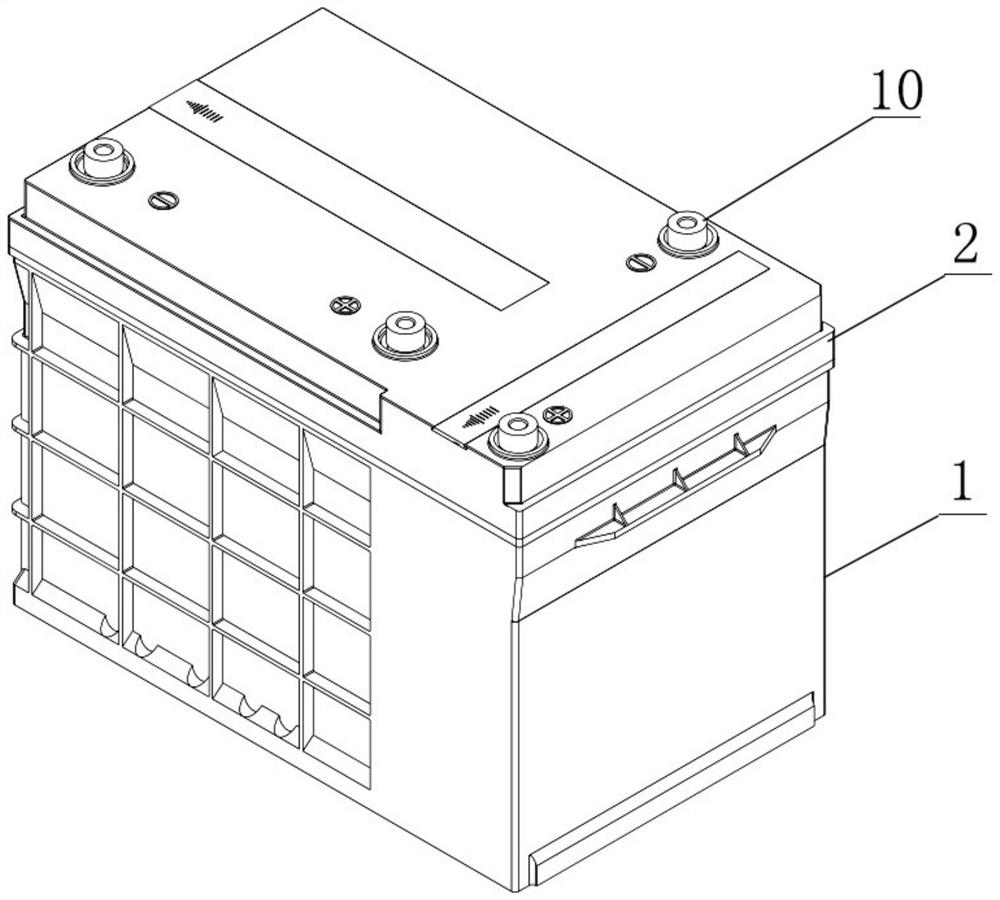

New energy automobile start-stop starting battery

A new energy vehicle and start-up battery technology, which is applied to batteries, electric vehicles, lead-acid batteries, etc., can solve the problems of short life of start-stop batteries, and achieve the effects of fast discharge response, strong current capacity, and guaranteed life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In this case, monomer B is matched with 10%, 20%, and 30% of the battery capacity of monomer A respectively. Using the blue electric test machine, Shengli VC189 plus PC terminal collects the current distribution, the recording point is 1s, and the recording time is 300s. The parallel matching of batteries occupies the percentage of current distribution respectively, see 10% matching Figure 5 , The monomer group B battery bears 100% to 38% of the current, and the monomer group A battery bears 0% to 62%. See you with 20% off Figure 6 , The monomer group B battery bears 100% to 57% of the current, and the monomer group A battery bears 0% to 43%. See you with 30% off Figure 7 , The battery group B of the single battery bears 100% to 72% of the current, and the battery group A of the single battery bears 0% to 28%. This shows that the discharge response speed of the single group B battery is fast and the current capacity is strong. It can play a role in short-term pow...

Embodiment 2

[0043] Cell B is the 10% life test of cell A capacity --- HRPSoC, the battery enters the test at 50% SoC, 2C current cycle charge and discharge, until the cut-off voltage cycle is completed, fully charged and then 50% SoC enters the test, such as Figure 8 . The pure battery group A of the single cell cannot be tested after a total of 8177 times in the 10th cycle, and the super start-stop starter battery of the battery group A in parallel with the battery group B of the single cell can still run, and the test is not continued until the 35th cycle after a total of 14979 times. Figure 9 . The principle is that when discharging for a short time, group B of the monomers, such as case 1, bears a large current. When it is left on hold for 10s, the balanced voltage of group A of the monomers will supply power to group B of the monomers. The two are voltage balanced again. From this experiment, it can be seen that the life of the monomer group B is significantly increased by 1 times...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com