Novel wood-plastic composite material

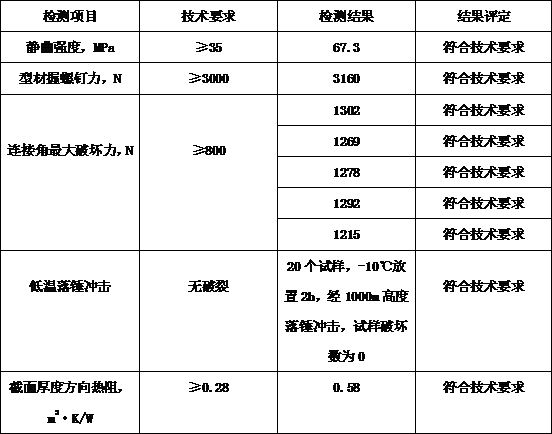

A wood-plastic composite material and a new type of technology, applied in the field of wood-plastic materials, can solve the problems of insufficient bending strength and connection stiffness, and achieve the effect of excellent impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1. In the embodiment of the present invention, a novel wood-plastic composite material includes the following components by weight: 45 parts of type 5 PVC powder, 45 parts of heavy calcium powder, 15.5 parts of talc powder, 18 parts of wood powder, stable 3 parts of modifier, 5 parts of modifier, 2 parts of acrylate, 0.5 part of internal lubricant, and 0.4 part of external lubricant, wherein, the fineness of talcum powder is 500 mesh, and the wood powder is one of wood chips, bamboo chips, straw or A variety of blends are obtained by pulverizing; the stabilizer is a lead salt stabilizer, the modifier is maleic anhydride grafted polypropylene or maleic anhydride grafted polyethylene, and the internal lubricant It is polyethylene wax, and the external lubricant is stearic acid.

Embodiment 2

[0017] Embodiment 2, in the embodiment of the present invention, a new type of wood-plastic composite material, including the following components by weight: 50 parts of type 5 PVC powder, 50 parts of heavy calcium powder, 12.5 parts of talc powder, 12.5 parts of wood powder, stable 2.5 parts of additives, 5 parts of modifiers, 1 part of acrylate, 0.5 parts of internal lubricants, and 0.4 parts of external lubricants. Among them, the fineness of talc powder is 500 mesh, and the wood powder is one of wood chips, bamboo chips, and straw. A variety of blends are obtained by pulverizing; the stabilizer is a lead salt stabilizer, the modifier is maleic anhydride grafted polypropylene or maleic anhydride grafted polyethylene, and the internal lubricant It is polyethylene wax, and the external lubricant is stearic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com