Lead refining and recycling system

A recovery system and furnace body technology, applied in the fields of dispersed particle filtration, gas treatment, membrane technology, etc., can solve the problems of low thermal efficiency of lead refining recovery system and ineffective utilization of flue gas waste heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

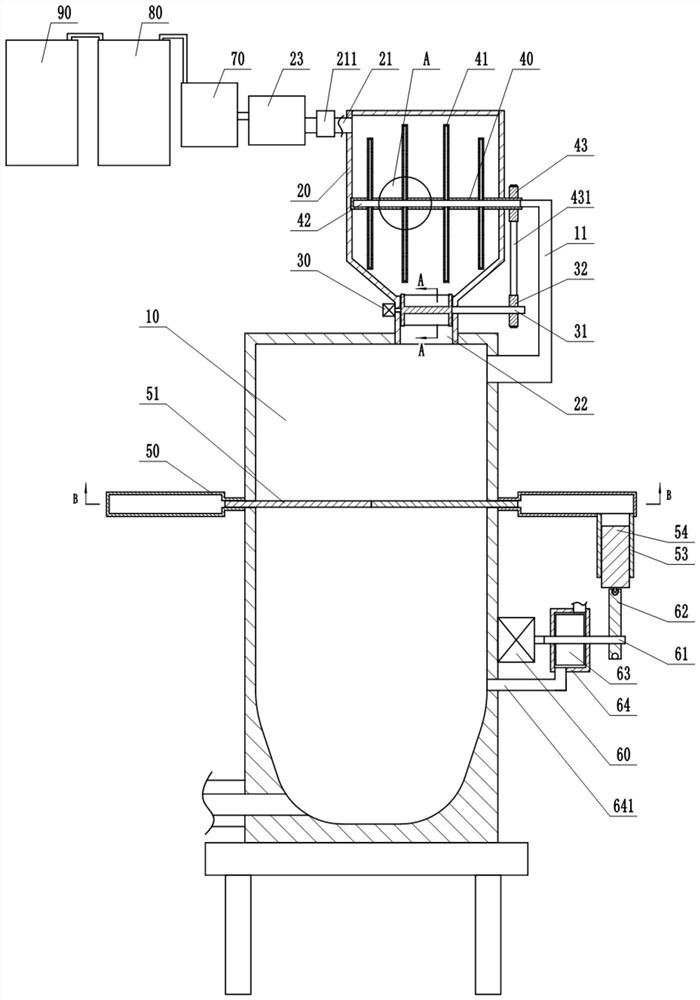

[0034] This embodiment is basically as figure 1 , figure 2 Shown: a lead refining recovery system, including a furnace body 10, a storage bin 20 and a discharge mechanism, the storage bin 20 is fixedly installed above the furnace body 10, the upper part of the storage bin 20 is connected to a recovery channel 21, and the recovery channel 21 is An air extraction mechanism is provided, and in this embodiment, the air extraction mechanism is an air extraction pump 211 . The discharge end of the recovery channel 21 is sequentially connected with a waste heat recovery mechanism, a dust removal mechanism 70 , an alkali removal mechanism and an acid removal mechanism 90 . A discharge channel 22 is connected to the lower part of the storage bin 20 , and the discharge channel 22 communicates with the upper part of the furnace body 10 .

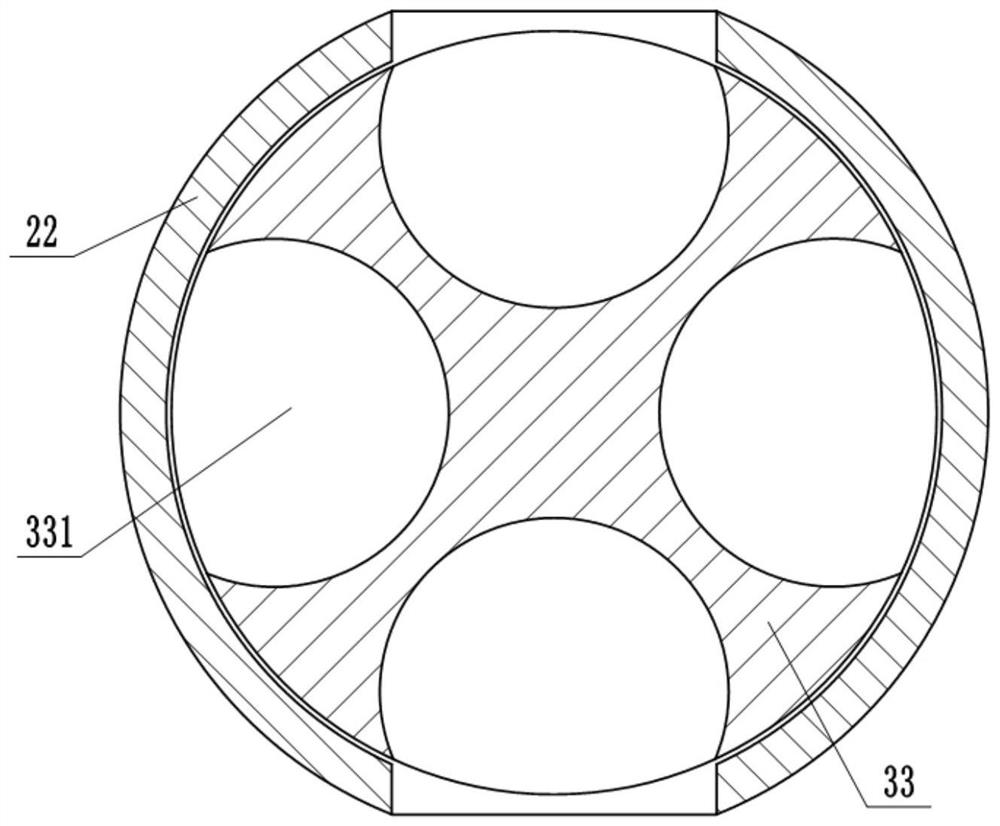

[0035] The discharge mechanism includes a motor 30 fixedly installed on the side wall of the discharge passage 22 and a discharge member rotatably ...

Embodiment 2

[0043] This embodiment limits the specific structures of the waste heat recovery mechanism, the dust removal mechanism 70 , the alkali removal mechanism and the acid removal mechanism 90 in the first embodiment. join Figure 5 As shown, in this embodiment, the waste heat recovery mechanism includes a water tank 23 , and a copper tube 231 is provided in the water tank 23 . One end of the copper tube 231 communicates with the recovery channel 21 and the other end communicates with the dust removal box 71 . After the flue gas passes into the copper tube 231, the heat of the flue gas is transferred to the water in the water tank 23 through the copper tube 231, which can make the temperature of the water rise rapidly.

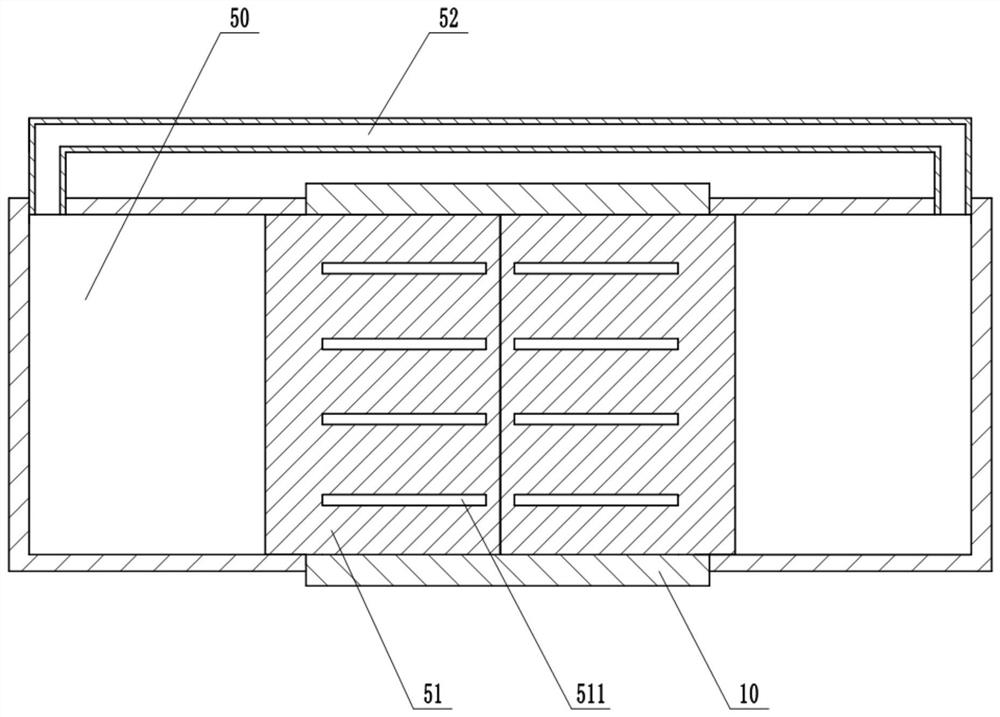

[0044] The dust removal mechanism 70 includes a dust removal box 71 and a filter part arranged in the dust removal box 71 , and the filter part includes a fixed sieve plate 77 , a movable sieve plate 76 and a power component driving the movable sieve plate 76 to rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com