Method for preparing Bi nanosheet by electrochemical stripping process

A nanosheet and exfoliation technology, applied in chemical instruments and methods, catalyst activation/preparation, nanotechnology, etc., can solve the problems of difficult realization of metal Bi and low melting point of metal bismuth, and achieve good industrialization prospects, high purity, and shape. uniform appearance and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040](1) Add 50mL of 0.5mol·L to the cathode and anode electrolytic cells of H-Cell (100mL specification) -1 NaI solution, and pass 20min N into the cathode electrolytic cell 2 ;

[0041] (2) Take the size as 5mm 3 , 99.99% pure metal Bi block is used as cathode, Pt sheet electrode is used as anode, DC regulated power supply provides 15V voltage, and N is continuously passed to the cathode electrolytic cell during power-on. 2 ;

[0042] (3) After energizing for 2 hours, the solution in the cathodic electrolytic cell was vacuum filtered by a vacuum filter, the precipitate was fully washed with ultrapure water, and the product was collected and dried in an electric vacuum oven at 80°C for 4 hours to obtain Bi nanosheets.

[0043] Characterization tests:

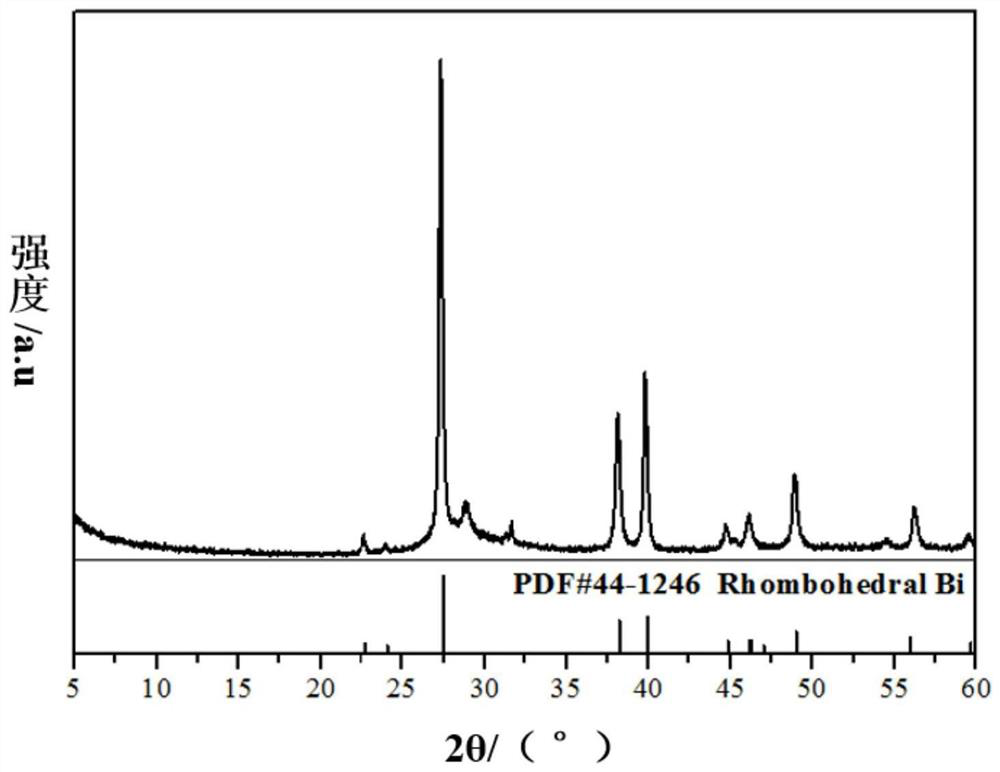

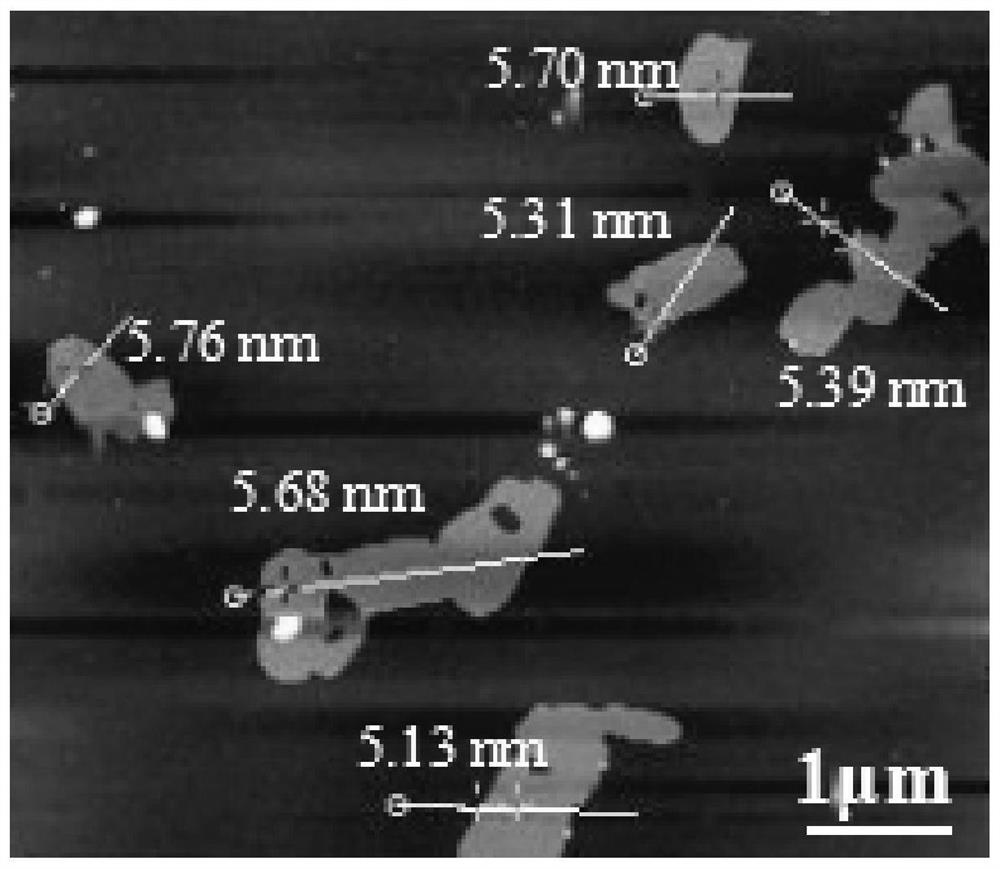

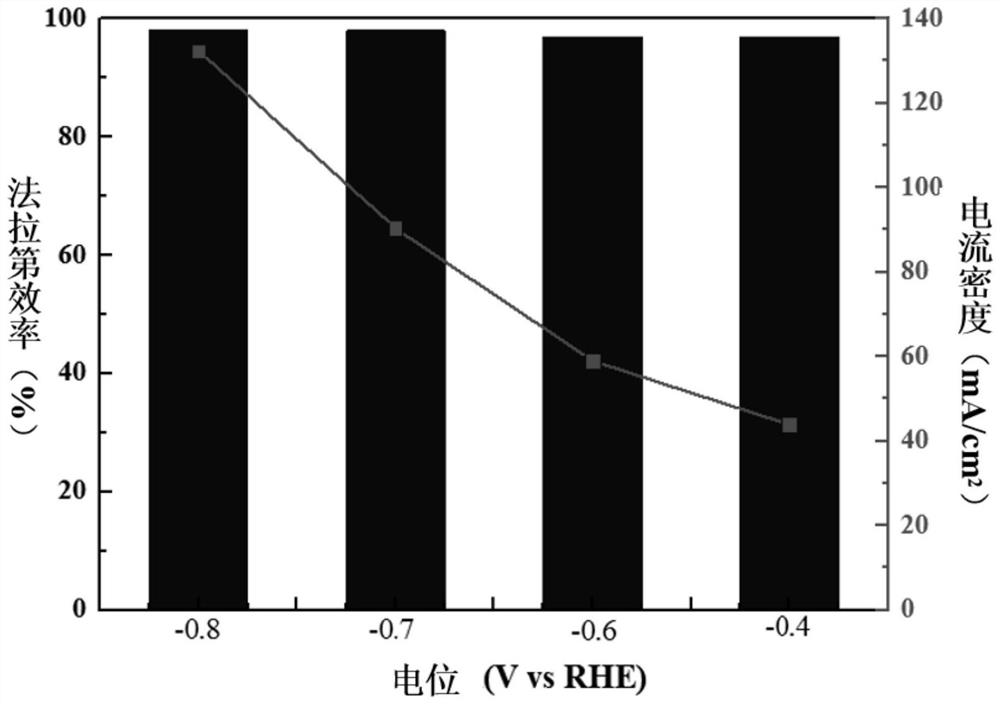

[0044] Carry out XRD test to the Bi nanosheet prepared in this embodiment, figure 1 For the XRD spectrum of the Bi nanosheets prepared in this example, the PDF card comparison proves that the prepared product is Bi. At th...

Embodiment 2

[0047] (1) Add 50mL of 1.0mol L to the cathode and anode electrolytic cells of H-Cell (100mL specification) -1 NaI solution, and pass 20min N into the cathode electrolytic cell 2 ;

[0048] (2) Take the size as 5mm 3 , 99.99% pure metal Bi block is used as cathode, Pt sheet electrode is used as anode, DC regulated power supply provides 30V voltage, and N is continuously passed to cathode electrolytic cell during power-on process 2 ;

[0049] (3) After energizing for 3 hours, the solution in the cathodic electrolytic cell was vacuum filtered by a vacuum filter, the precipitate was fully washed with ultrapure water, and the product was collected and dried in an electric vacuum oven at 60°C for 6 hours to obtain Bi nanosheets.

Embodiment 3

[0051] (1) Add 50mL of 0.7mol·L to the cathode and anode electrolytic cells of H-Cell (100mL specification) -1 NaI solution, and pass 20min N into the cathode electrolytic cell 2 ;

[0052] (2) Take the size as 5mm 3 , 99.99% pure metal Bi block is used as cathode, Pt sheet electrode is used as anode, DC regulated power supply provides 10V voltage, and N is continuously passed to the cathode electrolytic cell during power-on process 2 ;

[0053] (3) After electrifying for 4 hours, the solution in the cathodic electrolytic cell was vacuum filtered by a vacuum filter, the precipitate was fully washed with ultrapure water, and the product was collected and dried in an electric vacuum oven at 70°C for 5 hours to obtain Bi nanosheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com