Fatigue-resistant layered elastic body

An elastomer, fatigue-resistant technology, applied in the direction of spring mattresses, mattresses, other seating furniture, etc., can solve the problem of not being able to obtain durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

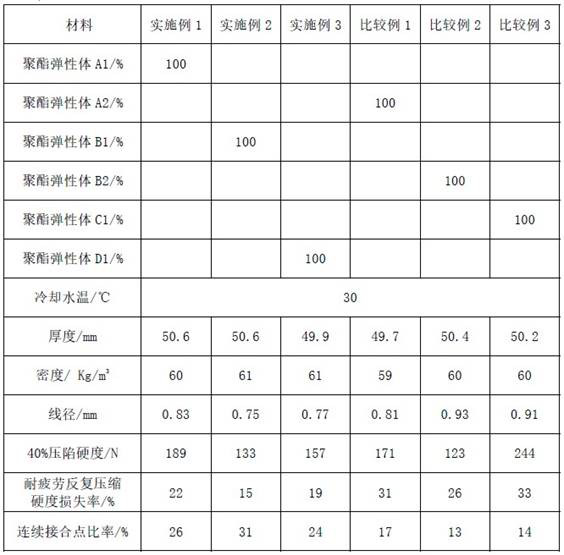

Embodiment 1

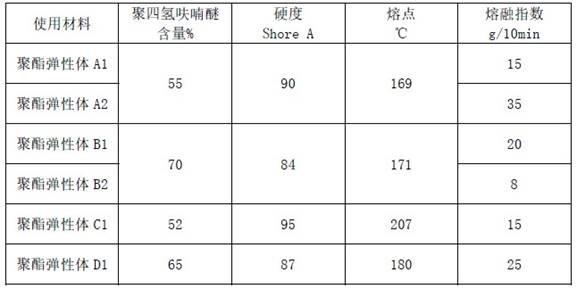

[0034] The raw material of polyester elastomer A1 is fed into the extruder, heated to 225°C in the extruder to a molten state, and transported to the spinneret by a metering pump, and the continuous line fiber is sprayed from the spinneret and falls into the water to bend into a ring , the contact parts between the thread bodies are welded to each other, the traction speed is 0.4 m / min, infrared heat insulation is used between the spinning plate and the lower water tank, and the woven continuous line body fibers are compressed by the mold in warm water at 30°C until both sides are flat Finally, the three-dimensional layered elastomer 3 is obtained by molding. The layered elastomer 3 is tested by the above method, and the physical parameters are shown in Table 2. The network structure density of the layered elastomer 3 is 60kg / m 3 , the obtained layered elastomer 3 has a continuous junction ratio of 26%, a 40% indentation hardness of 189N, and a fatigue-resistant hardness loss r...

Embodiment 2

[0036] The specific implementation method is the same as in Example 1, but the raw material used is changed to polyester elastomer B1, the continuous junction ratio of the obtained layered elastomer 3 is 31%, the 40% indentation hardness is 133N, and the hardness after repeated compression of fatigue resistance The loss rate is 15%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com