Flexible core-shell heterostructure positive electrode material and preparation method and application thereof

A technology of heterostructure, cathode material, applied in nanotechnology for materials and surface science, chemical instruments and methods, hybrid capacitor electrodes, etc., can solve the problems of low specific capacity of supercapacitor electrode materials and achieve large specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] On the other hand, an embodiment of the present invention also provides a method for preparing the above-mentioned flexible electrode material, including the following steps:

[0044] S1, carbon cloth cleaning;

[0045] S2, prepare Co(CO 3 ) 0.35 Cl 0.2 (OH) 1.1 1.74H 2 O / CC: Fill the cleaned carbon cloth into 30mL containing CoCl 2 ·6H 2 O and urea were reacted in a high-pressure reactor with deionized water. After the reactor was naturally cooled to room temperature, the pink product was washed with deionized water and ethanol several times, dried in vacuum at 50°C for 12 hours, and then used after cooling;

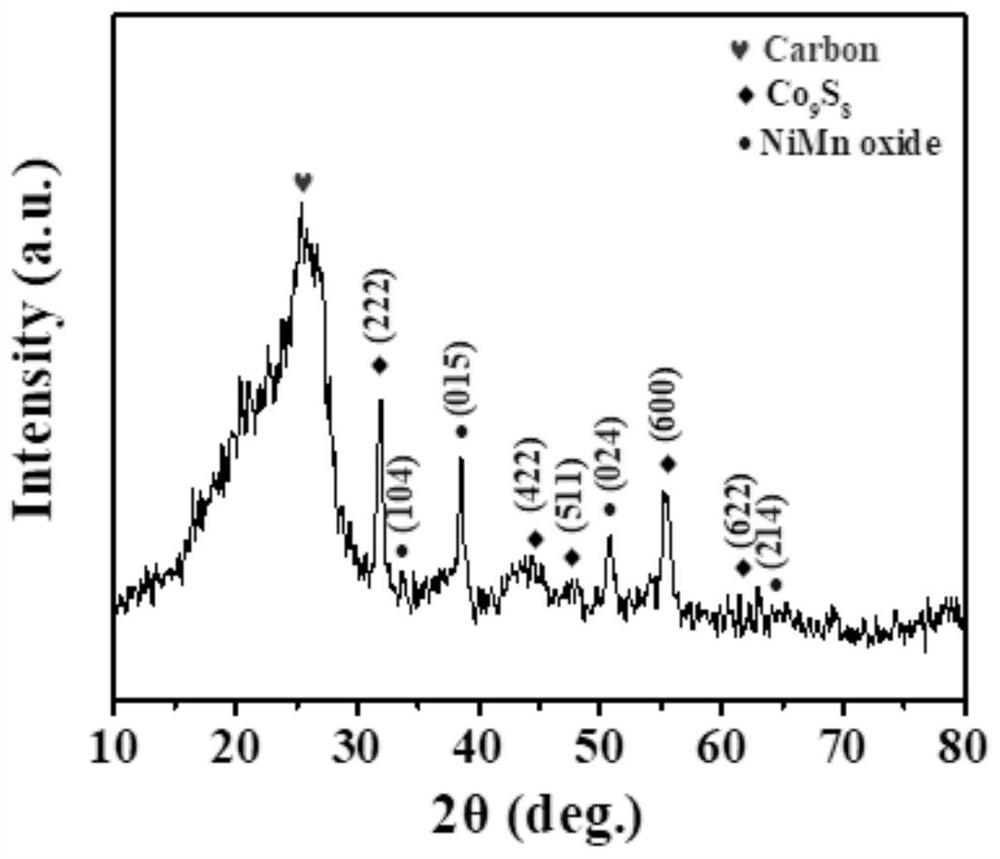

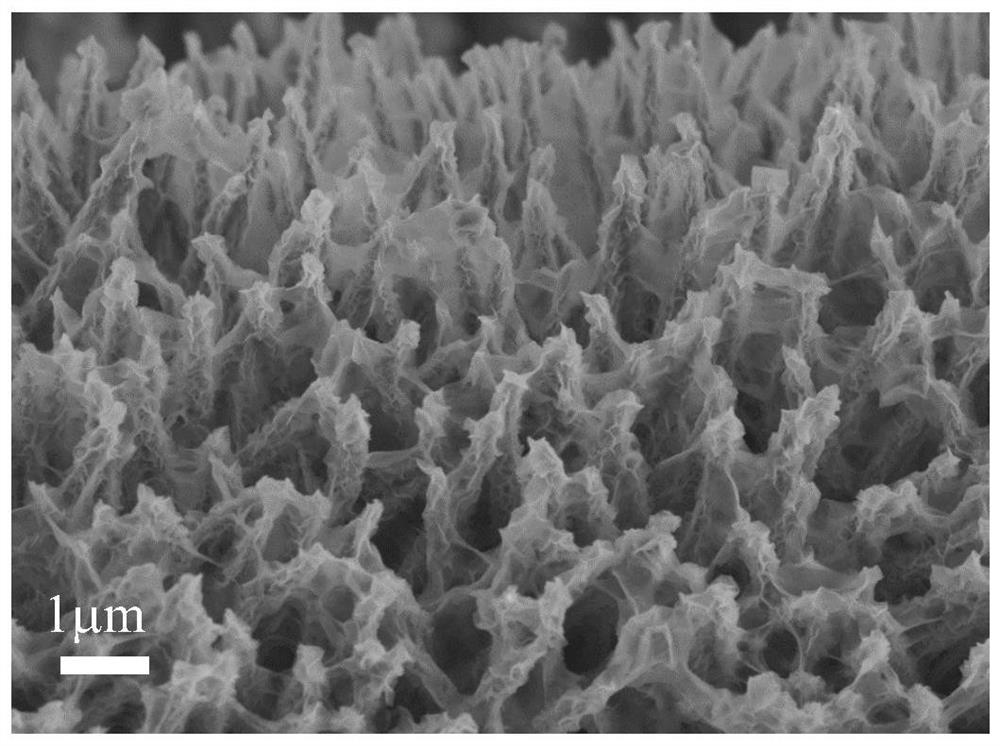

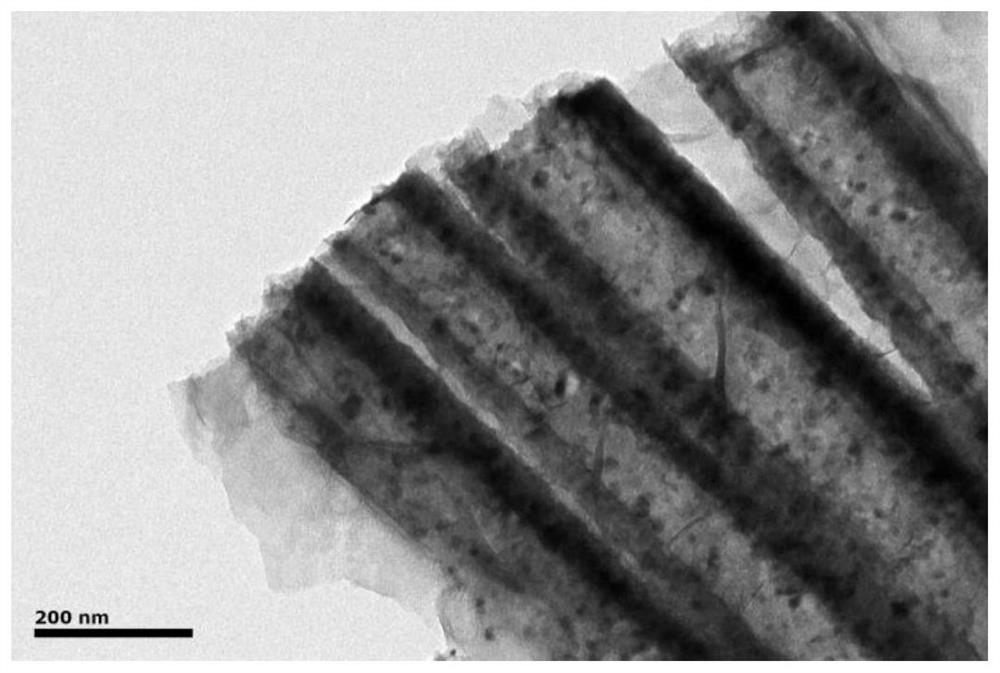

[0046] S3, preparation of Co 9 S 8 / CC: Co(CO 3 ) 0.35 Cl 0.2 (OH) 1.1 1.74H 2 O / CC into 30mL containing Na 2 The reaction was carried out in a high-pressure reactor of the S solution, and after the reactor was naturally cooled to room temperature, the product was washed several times with deionized water and ethanol, dried in vacuum at 50°C for 12 ...

Embodiment 1

[0059] (1)Co(CO 3 ) 0.35 Cl 0.2 (OH) 1.1 1.74H 2 Preparation of O / CC samples: first place the carbon cloth (2cm×3cm) into acetone, hydrochloric acid (3M), absolute ethanol and deionized water, respectively, and sonicate each for 15min in turn. Then put the cleaned carbon cloth into 30mL containing 75mM CoCl 2 ·6H 2 O and 0.5mM urea deionized water in a high-pressure reactor, hydrothermal reaction at 90 ° C for 6 h, after the reactor was naturally cooled to room temperature, the pink product was washed several times with deionized water and ethanol, and vacuum-dried at 50 ° C for 12 h , to be used after cooling;

[0060] (2)Co 9 S 8 / CC sample preparation: Co(CO 3 ) 0.35 Cl 0.2 (OH) 1.1 1.74H 2 O / CC samples were put into 30mL containing 0.5M Na 2 In the high-pressure reaction kettle of S solution, hydrothermal reaction was carried out at 150°C for 10 hours. After the reaction kettle was naturally cooled to room temperature, the product was washed several times wit...

Embodiment 2

[0063] (1)Co(CO 3 ) 0.35 Cl 0.2 (OH) 1.1 1.74H 2 Preparation of O / CC samples: first place the carbon cloth (2cm×3cm) into acetone, hydrochloric acid (3M), absolute ethanol and deionized water, respectively, and sonicate each for 15min in turn. Then put the cleaned carbon cloth into 30mL containing 75mM CoCl 2 ·6H 2 O and 0.5mM urea deionized water in a high-pressure reactor, hydrothermal reaction at 90 ° C for 6 h, after the reactor was naturally cooled to room temperature, the pink product was washed several times with deionized water and ethanol, and vacuum-dried at 50 ° C for 12 h , to be used after cooling;

[0064] (2)Co 9 S 8 / CC sample preparation: Co(CO 3 ) 0.35 Cl 0.2 (OH) 1.1 1.74H 2 O / CC samples were put into 30mL containing 0.5M Na 2 In the high-pressure reaction kettle of S solution, hydrothermal reaction was carried out at 150°C for 10 hours. After the reaction kettle was naturally cooled to room temperature, the product was washed several times wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com