Method for manufacturing PEEK bone fixation part containing carbon fiber filaments through heat flow die casting

A technology of carbon fiber filaments and bone fixation, which is applied in fixers, fastening devices, internal bone synthesis, etc., can solve the problems of inability to obtain mechanical effects, difficult quality assurance, and complicated processes, so as to avoid step effect and improve mechanical properties. , the effect of dense material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

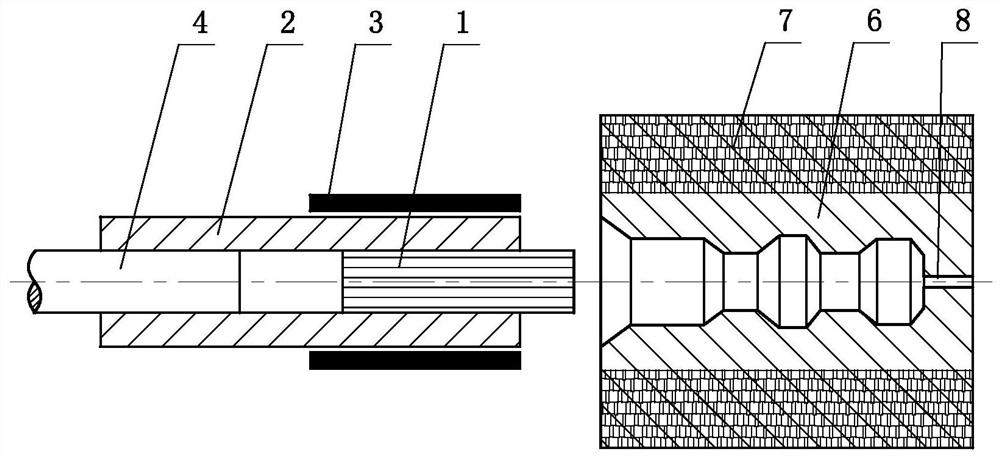

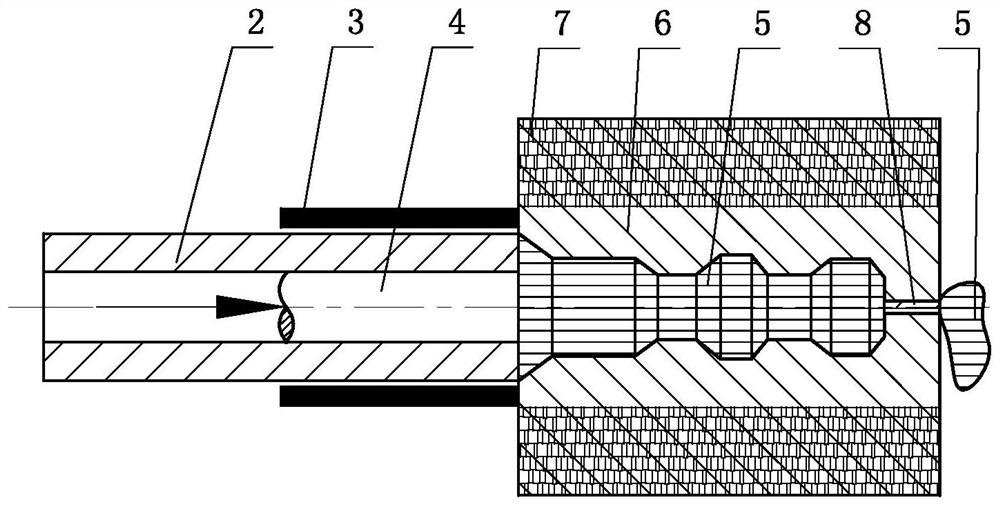

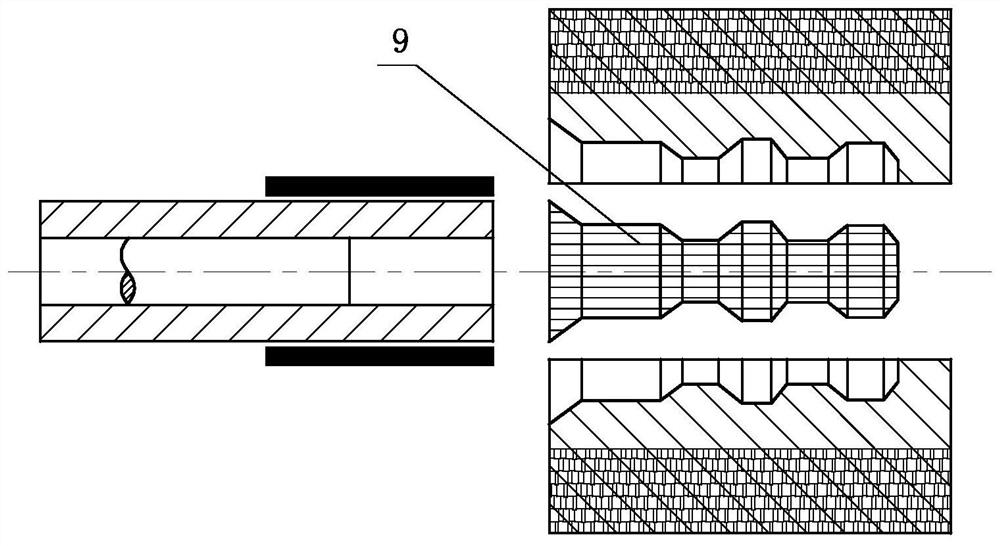

[0056] The implantable bone screw is a columnar structure with a large size in the main load-bearing direction, a certain central symmetry in the outline, and holes, threads, steps and other features in the details. Such as Figure 4 shown. In the axial direction of the bone screw, the carbon fiber filaments in the PEEK material are distributed along the axial direction of the bone screw, which can maximize the axial strength and stiffness. In the tangential direction of the bone screw, especially in the thread direction, the carbon fiber filaments in the PEEK material are wound on the screw spindle along the thread direction (tangential direction). This filament winding method can enhance the resistance of the screw (especially in the thread area). torsional stability and thread strength. In the transition region, the carbon fiber filaments in the PEEK material are distributed in a gradual transition manner, showing a continuous transition of mechanical properties. Such as...

Embodiment 2

[0058] The implant-grade bone plate is a long plate-like structure with a large size in the main load-bearing direction, a certain degree of curvature in the length direction, and a small size outside the main load-bearing direction, with holes, chamfers, and steps and other features. Such as Figure 6 , Figure 7 shown. The implant-grade bone plate is manufactured by hot flow molding process. In the length direction of the bone plate, the carbon fiber filaments in the PEEK material are continuously distributed along the length direction, which can maximize the axial strength and stiffness. At the opening of the bone plate, the carbon fiber filaments in the PEEK material are squeezed by the heat flow of the material during the molding process, and the carbon fiber filaments are formed at the opening to gather along the shape of the opening (the fibers are distributed along the hole), ensuring that the carbon fiber While the filaments are continuous, the distribution directi...

Embodiment 3

[0060] The intervertebral fusion cage has a block structure with a relatively complex internal space structure, and features such as holes, threads, waves, steps, and convex point arrays. Such as Figure 9 shown. The intervertebral fusion cage is manufactured by the heat flow molding process. At the steps and threads of the intervertebral fusion cage, the carbon fiber filaments in the PEEK material are distributed along the steps and thread directions to enhance the torsional stability and stability of the steps and thread areas. area strength. At the opening of the intervertebral fusion device, the carbon fiber filaments are squeezed apart by the heat flow of the material during the molding process, and the carbon fiber filaments are formed at the opening to gather along the shape of the opening (the fibers are distributed along the hole), ensuring that the carbon fiber length While maintaining the continuity of the filaments, the distribution direction of the carbon fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com