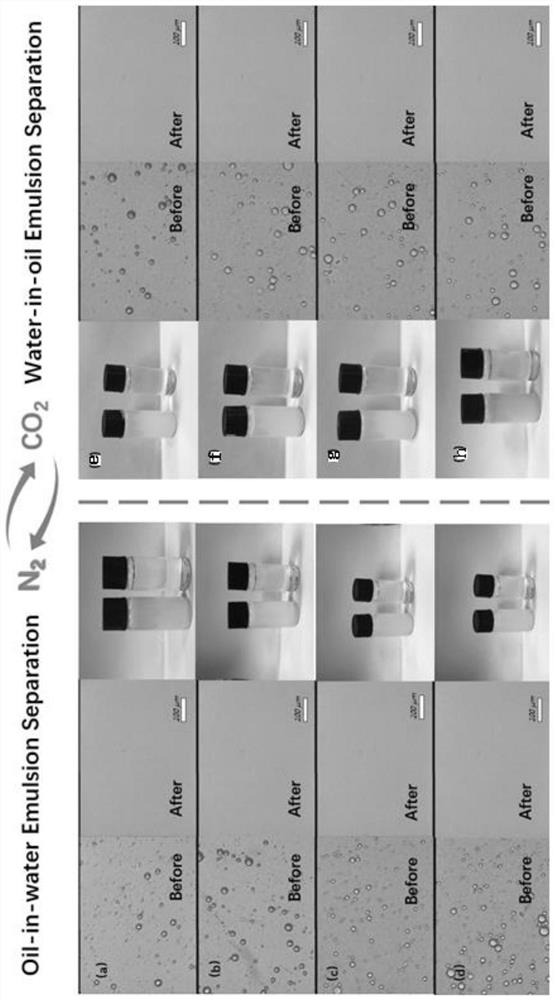

Magnetic nano material with CO2 responsiveness as well as preparation method and application thereof

A magnetic nano, responsive technology, applied in nanotechnology, separation methods, nanotechnology and other directions for materials and surface science, can solve the problems of low separation efficiency, difficult to control polymerization process, low selectivity of response materials, etc. The reaction process is simple, mature and stable, and the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Preparation of magnetic halloysite: add 3g of halloysite and disperse evenly in 60ml of ethanol by ultrasonic. Then 2g of ferric nitrate nonahydrate was added, ultrasonicated, stirred at room temperature, and vacuum-dried at 90°C to obtain an orange powder. The obtained solid powder was impregnated with ethylene glycol, and then placed in a tube furnace with N 2 Calcined at a high temperature of 400°C for 4h. The product obtained by calcining at high temperature is fully washed with ethanol and dried;

[0038] (2) Preparation of magnetic halloysite@dopamine: add 0.0909 g (0.75 mmol) of trishydroxyaminomethane to 150 ml of deionized water. After it is completely dissolved, adjust the pH to 8.5 with dilute hydrochloric acid to obtain a buffer solution. Subsequently, 3 g of magnetic halloysite powder, 5 ml of ethanol and 0.15 g of dopamine were added to the buffer solution, stirred at room temperature and suction filtered. The obtained powder was washed 3 times wit...

Embodiment 2

[0043] (1) Preparation of magnetic halloysite: add 3.0 g of halloysite, and disperse evenly in 60 ml of ethanol by ultrasonic. Then add 2.0 g of ferric nitrate nonahydrate and ultrasonicate. Then it was stirred at room temperature, and dried under vacuum at 90°C to obtain an orange powder. The obtained solid powder was impregnated with ethylene glycol, and then placed in a tube furnace with N 2 Calcined at a high temperature of 400°C for 4h. The product obtained by calcining at high temperature is fully washed with ethanol and dried;

[0044] (2) Preparation of magnetic halloysite@dopamine: add 0.0909 g (0.75 mmol) of trishydroxyaminomethane to 150 ml of deionized water. After it is completely dissolved, adjust the pH to 8.5 with dilute hydrochloric acid to obtain a buffer solution. Subsequently, 3.0 g of magnetic halloysite powder, 5 ml of ethanol and 0.15 g of dopamine were added to the buffer solution, stirred at room temperature and suction filtered. The obtained powd...

Embodiment 3

[0049] (1) Preparation of magnetic halloysite: add 3.0 g of halloysite, and disperse evenly in 60 ml of ethanol by ultrasonic. Then add 2.0 g of ferric nitrate nonahydrate and ultrasonicate. Stir at room temperature and vacuum-dry at 90°C to obtain an orange powder. The obtained solid powder was impregnated with ethylene glycol, and then placed in a tube furnace with N 2 Calcined at 400°C for 4h. The product obtained by calcining at high temperature is fully washed with ethanol and dried;

[0050] (2) Preparation of magnetic halloysite@dopamine: add 0.0909 g (0.75 mmol) of trishydroxyaminomethane to 150 ml of deionized water. After it is completely dissolved, adjust the pH to 8.5 with dilute hydrochloric acid to obtain a buffer solution. Subsequently, 3.0 g of magnetic halloysite powder, 5 ml of ethanol and 0.15 g of dopamine were added to the buffer solution, stirred at room temperature and suction filtered. The obtained powder was washed 3 times with deionized water, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com