Cylinder structure of large modular mill

A modular, cylinder technology, applied in the direction of grain processing, etc., can solve the problems of high ball loading rate, incapable of dry grinding, high energy consumption, etc., to achieve convenient processing, manufacturing and transportation, dry grinding and wet grinding universal , the effect of high ball loading rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

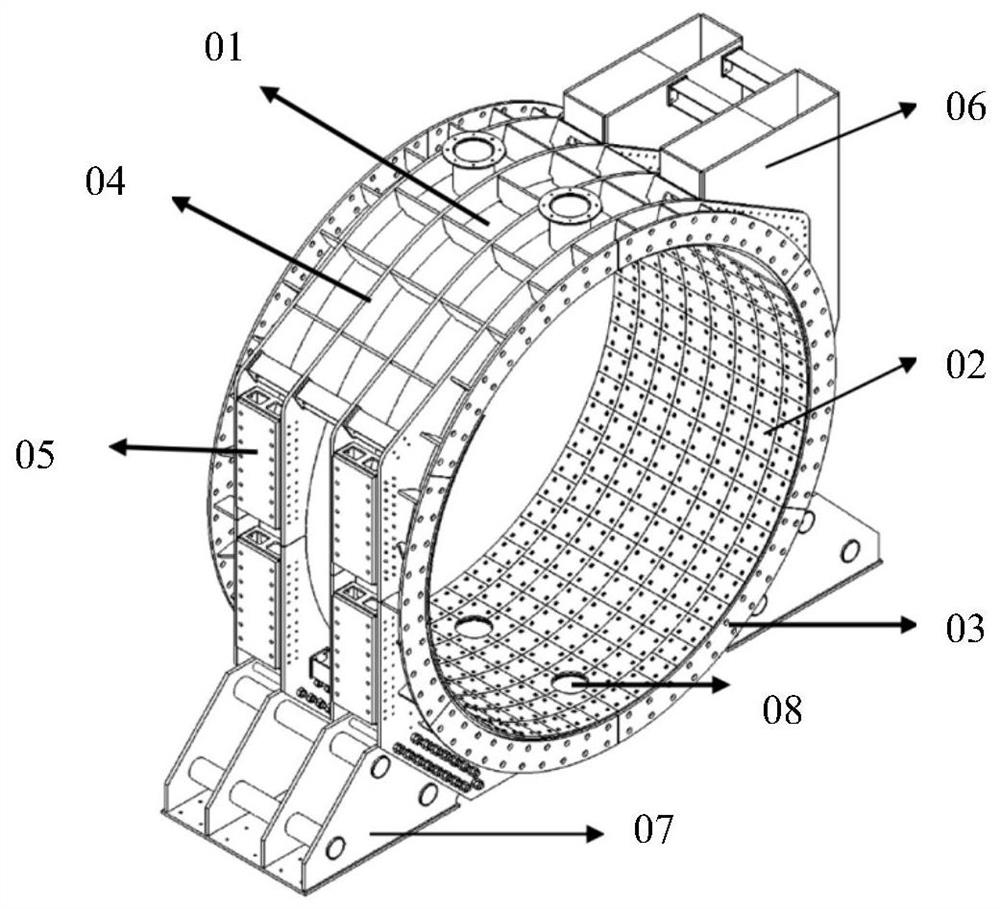

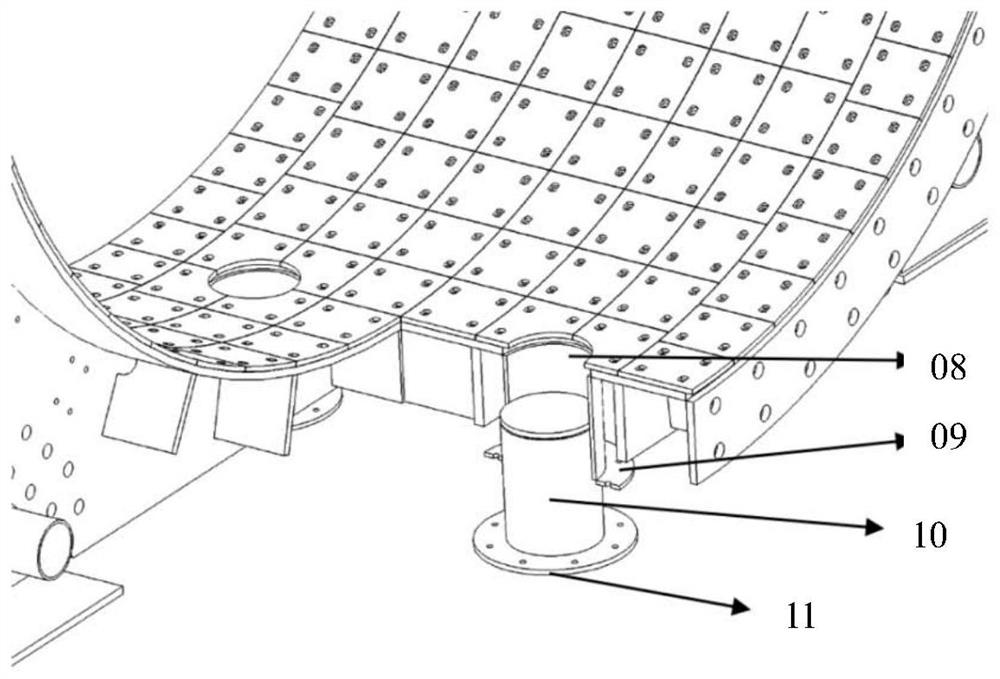

[0022] Embodiment 1, a cylinder structure of a large modular mill, including several interconnected cylinders 01 . Such as figure 1 As shown, a wear-resistant liner 02 is laid inside the cylinder 01, and the cylinder 01 is a cylindrical structure with both ends penetrating. End flanges 03 are respectively welded at both ends of the cylinder body 01 , and two adjacent cylinder bodies 01 are connected through the end flanges 03 respectively. At least one annular flange 04 is sheathed on the outer surface of the cylinder 01 , and one side of the cylinder is connected to an excitation device installation base 05 through at least one annular flange 04 , and the excitation device installation base 05 is connected to a vibrator. The other side of the cylinder 01 is connected with a counterweight 06 through at least one annular flange 04, and the counterweight 06 is used to adjust the weight of both sides of the cylinder 01; the lower ends of both sides of the cylinder 01 are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com