Novel antibacterial and mildew-proof paint film and preparation method thereof

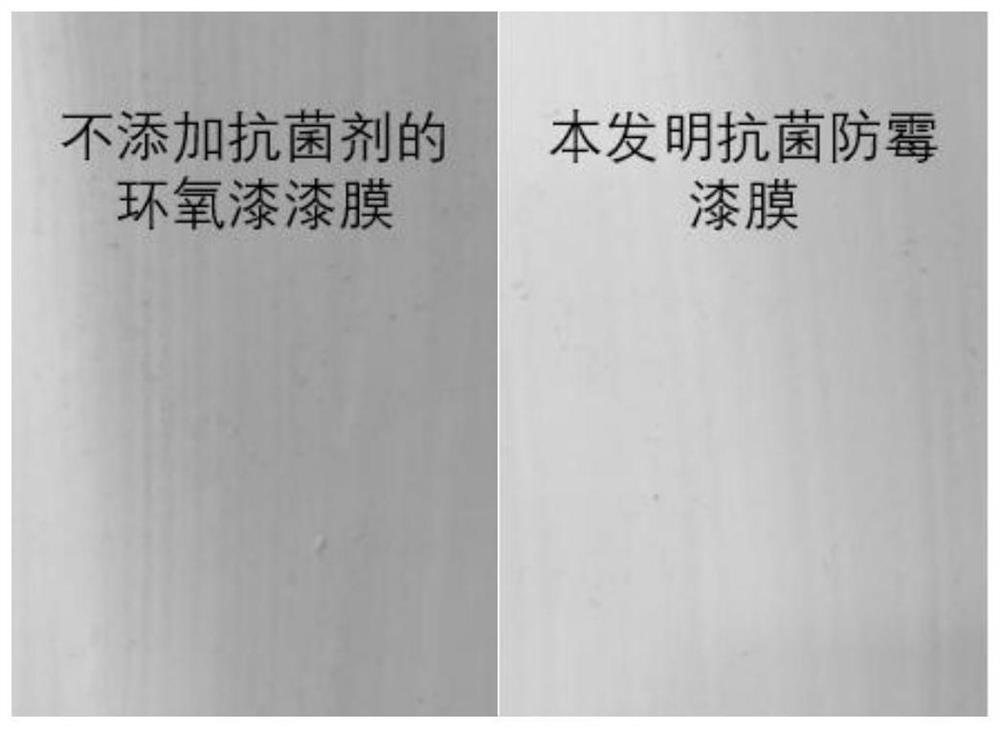

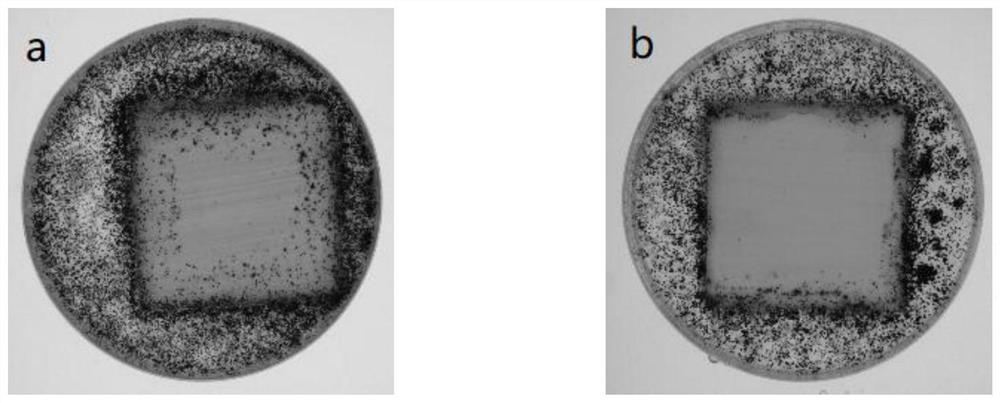

An antibacterial, antifungal, and paint film technology, which is applied to biocide-containing paints, antifouling/underwater coatings, coatings, etc., can solve problems such as environmental pollution and reduced antibacterial performance of paints, and achieve simple preparation methods and antibacterial effects Long lasting, less polluting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh 5g of polyethyleneimine with a molecular weight of 1800 and 15.8g of bromododecane and dissolve them in 19g of isopropanol, respectively, and mix and stir to form a homogeneous solution; the above two solutions are mixed and heated to 50 ° C and react for 48h; The ester is precipitated and dried to obtain a solid antibacterial agent quaternized polyethyleneimine.

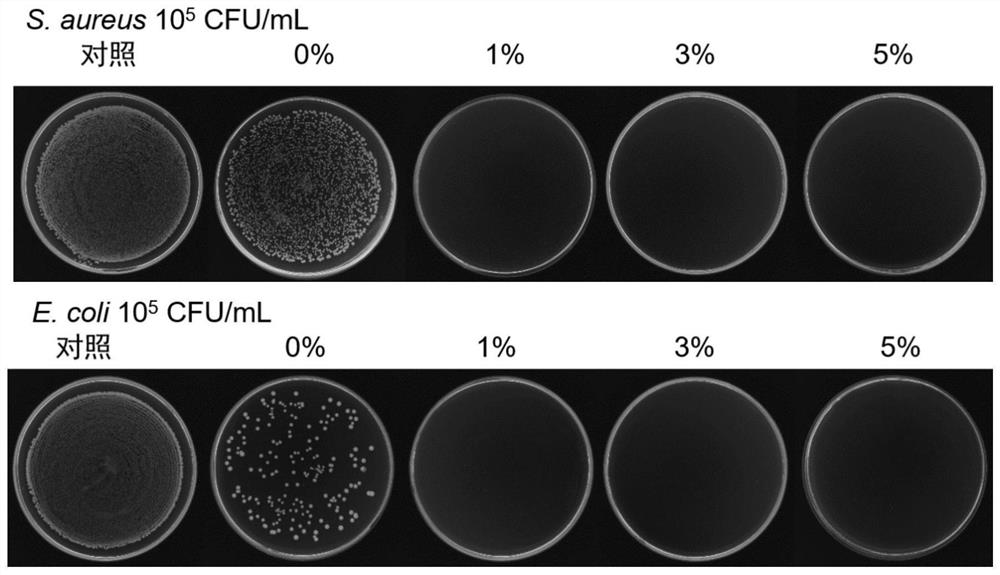

[0031] Weigh 25.7g 601 resin, 23.1g xylene, 5.8g n-butanol, mix and stir, and add 40.4g other fillers (17.7g titanium dioxide, 8g barium sulfate, 3.2g kaolin, 11.2g after 601 resin is completely dissolved) Mica powder, 0.3g organoclay, ground for two hours; 5g of quaternized polyethyleneimine was weighed and dissolved in the xylene solution, added to the above mixture, continued to grind for 5min, and then added 5g of component B (3.1g of T31 curing agent) , 651 curing agent 1.9g), mixed evenly. Brush it on the surface of the metal substrate with a brush, and dry it to obtain an antibacterial and mildew...

Embodiment 2

[0035] Weigh 5g of polyethyleneimine with a molecular weight of 10000 and 15.8g of bromododecane and dissolve them in 19g of isopropanol, respectively, and mix and stir to form a homogeneous solution; mix and heat the above two solutions to 50 ° C, and react for 48h; use ethyl acetate The ester is precipitated and dried to obtain a solid antibacterial agent quaternized polyethyleneimine.

[0036] Weigh 25.7g 601 resin, 23.1g xylene, 5.8g n-butanol, mix and stir, and add 40.4g other fillers (17.7g titanium dioxide, 8g barium sulfate, 3.2g kaolin, 11.2g after 601 resin is completely dissolved) Mica powder, 0.3g organoclay), ground for two hours; 5g of quaternized polyethyleneimine was weighed and dissolved in the xylene solution, added to the above mixture, continued to grind for 5min, and then added 5g of component B (T31 curing agent 3.1 g, 651 curing agent 1.9g), mix well. Apply it on the surface of the metal substrate with a brush and let it dry to obtain an antibacterial a...

Embodiment 3

[0040] Weigh 5g of polyethyleneimine with a molecular weight of 25000 and 15.8g of bromododecane and dissolve them in 19g of isopropanol, respectively, and mix and stir to form a homogeneous solution; mix and heat the above two solutions to 50 ° C, and react for 48h; use ethyl acetate The ester is precipitated and dried to obtain a solid antibacterial agent quaternized polyethyleneimine.

[0041] Weigh 25.7g 601 resin, 23.1g xylene, 5.8g n-butanol, mix and stir, and add 40.4g other fillers (17.7g titanium dioxide, 8g barium sulfate, 3.2g kaolin, 11.2g after 601 resin is completely dissolved) Mica powder, 0.3g organoclay), ground for two hours; 5g of quaternized polyethyleneimine was weighed and dissolved in the xylene solution, added to the above mixture, continued to grind for 5min, and then added 5g of component B (T31 curing agent 3.1 g, 651 curing agent 1.9g), mix well. Apply it on the surface of the metal substrate with a brush and let it dry to obtain an antibacterial a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com