Carbon-doped yarn and production method

A production method and yarn technology, applied in the field of carbon-doped yarn and its production, can solve the problems of low strength of acrylic-doped carbon fiber and difficulty in spinning acrylic-doped carbon fiber, and achieve high anti-toxicity and resistance flammability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

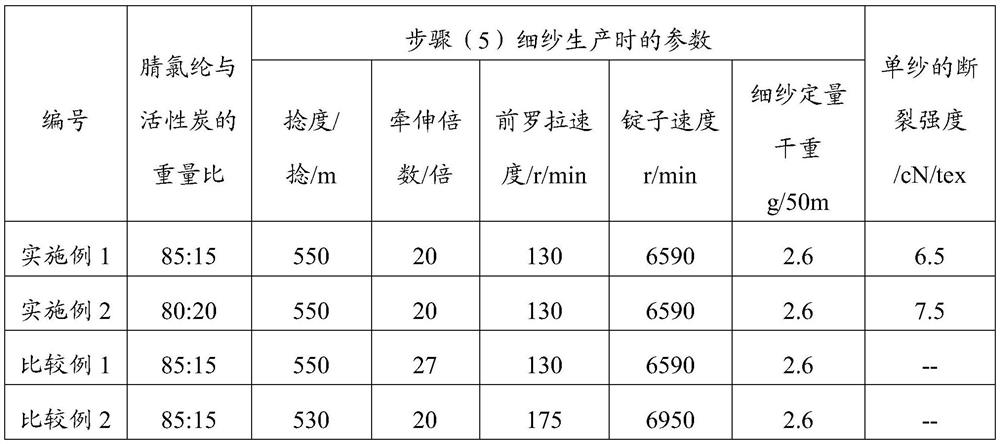

Embodiment 1

[0071] (1) Cleaning and carding: the selected acrylic-chlorinated fiber mixed with carbon fiber raw material is mixed, opened and cleaned by a cotton cleaning machine; the acrylic-chlorinated fiber-doped carbon fiber after cleaning is fed into the carding machine, Further remove impurities and non-spinnable fibers, and obtain raw sliver; wherein, in the acrylic fiber mixed with carbon fiber, the weight ratio of acrylic fiber and activated carbon is 85:15; the linear density of acrylic fiber mixed with carbon fiber is 3.6dtex, the linear density The density deviation is 9%, the breaking strength is 1.6cN / dtex, and the breaking elongation is 25%;

[0072] (2) Sliver making: the raw sliver is made into a uniform yarn line using a pressure roller and a coiling device, wherein the front roller speed is 112r / min;

[0073](3) Drawing: the yarn line is sent into the drawing frame, and through the merging-drawing-mixing-striping process, the cooked strips are obtained; wherein, the coo...

Embodiment 2

[0079] The only difference from Example 1 is that, in the carbon-doped acrylic fiber, the weight ratio of acrylic fiber to activated carbon is 80:20.

[0080] The linear density of the carbon-doped yarn (single yarn) obtained in this embodiment is 28.5tex, and the linear density deviation is 2.5%, and the breaking strength of yarn is 7.5cN / tex, and the breaking strength CV value is 16%, and the amount of benzene absorption is 5.1%. Two single yarns are twisted to obtain two strands, the linear density of the strands is 59tex, the deviation of the linear density is 2.5%, the breaking strength of the yarn is 9.0cN / tex, and the CV value of the breaking strength is 12%. The twist is 450 twists / m, and the twist unevenness is 6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com