Thermal safety monitoring method for lithium ion battery under dynamic pressure and variable temperature conditions

A lithium-ion battery, safety monitoring technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of inaccurate selection of critical value of characteristic parameters of battery thermal runaway, without considering sensor delay and error, etc., to achieve good transplantation performance, improve efficiency and accuracy, and evenly heat the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

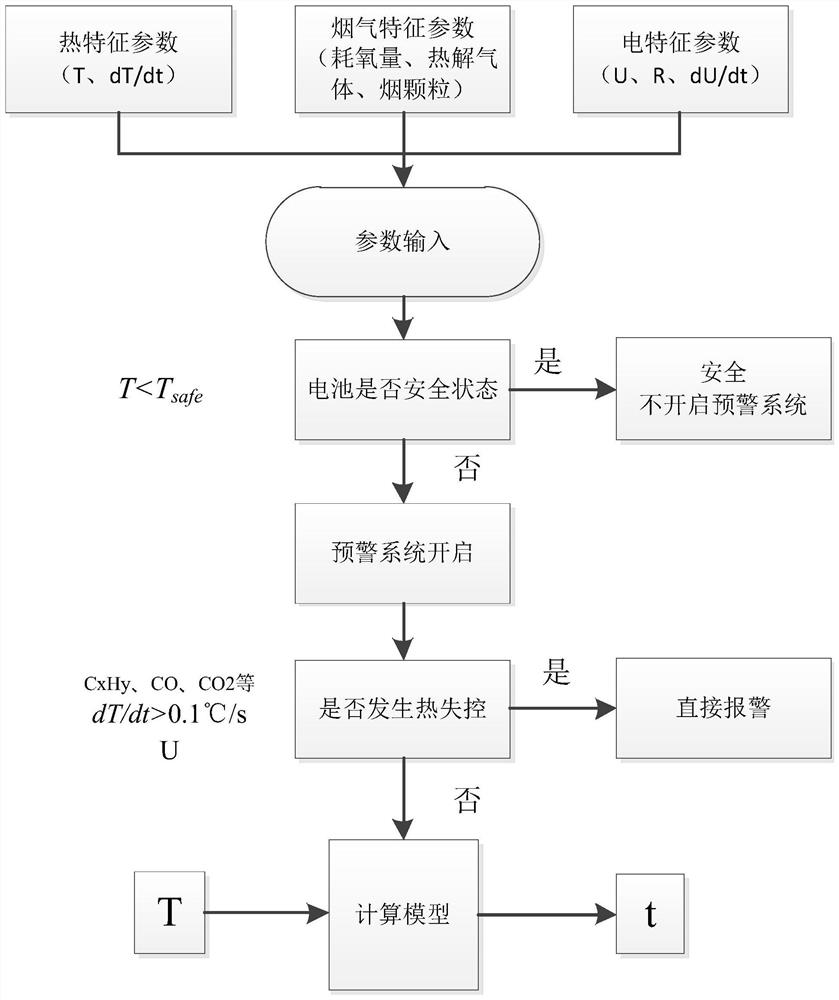

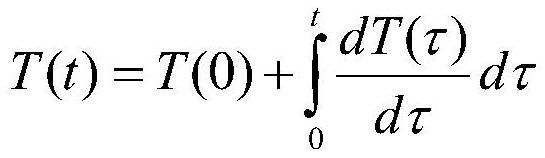

[0053] Such as figure 1 As shown, Embodiment 1 is a thermal safety monitoring method for lithium-ion batteries under the condition of dynamic pressure and variable temperature. Input the data collected by each monitoring sensor into the external data processor in real time to complete the collection and monitoring of multiple parameters of the lithium-ion battery; screen the parameters and input the monitored parameters into the thermal runaway warning system of the lithium-ion power battery, if the battery The temperature exceeds T>T safe , then it is judged that the battery is in danger of thermal runaway, and the monitoring is continued; if it does not exceed, it is judged that the battery is in a safe state, and the system enters standby; further combined with the change of pyrolysis flue gas concentration, open circuit voltage change, and temperature rise rate change to judge the battery Whether thermal runaway occurs, the judgment result is that the battery has thermal ...

Embodiment 2

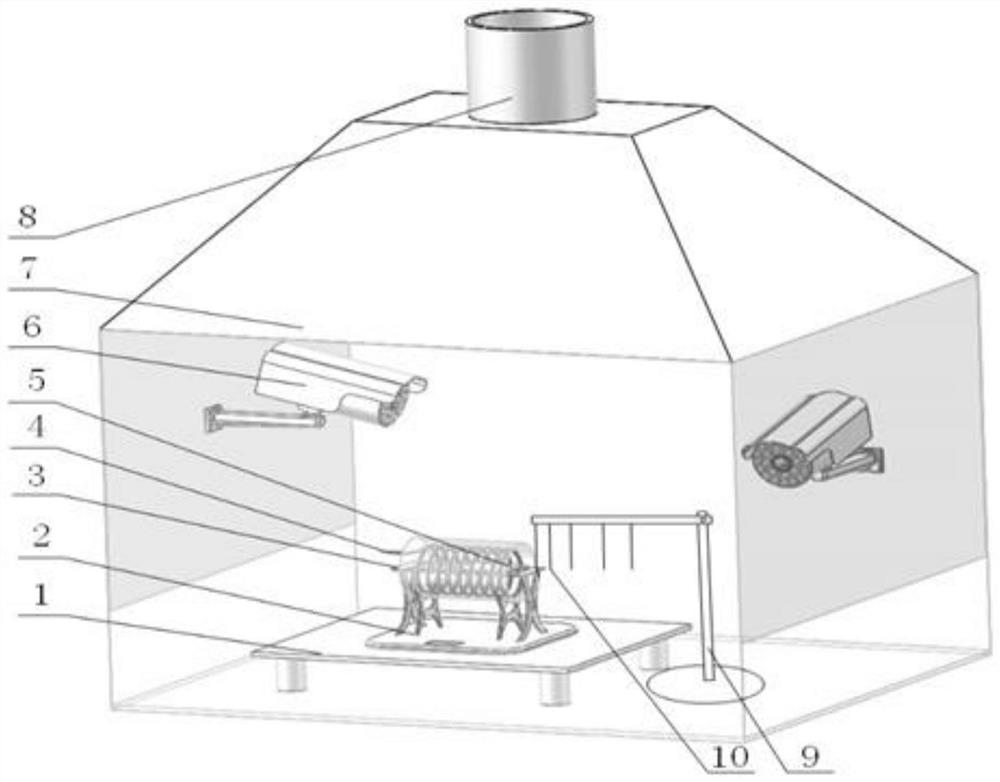

[0055] Such as figure 2 As shown, a lithium-ion battery thermal safety monitoring device using the method of Example 1 under the condition of dynamic pressure and variable temperature. Build the experimental inner cabin, its specification is: 800x600x600mm, the experimental cabin can effectively prevent fire and explosion and prevent the damage of battery spray. An electronic scale 2 is arranged at the bottom of the inner cabin of the experiment to record the quality change of the battery before and after thermal runaway; the battery is fixed by a special clamping frame 3 and the open circuit voltage data is conveniently collected; the radiation heat runner 4 is arranged to simulate a real external heat source, and the lithium The ion battery 5 carries out 360° radiation heating of the ring body, and the temperature and temperature rise rate can be controlled; the thermocouple groups 10 are arranged at equal intervals on the thermocouple bracket 9 and the surface of the lithi...

Embodiment 3

[0098] Embodiment 3 is based on Embodiment 2 and includes the following steps.

[0099] (1) Based on the existing experimental platform: dynamic pressure variable temperature experimental cabin and calorimeter, thermal runaway experiments of lithium-ion batteries of different quantities and scales can be realized, and the flight dynamic pressure variable temperature environment can be fully simulated, and the experiment has been well transplanted Parameters to be measured can be added according to specific needs (such as: voltage, internal resistance, smoke density and smoke composition, etc.);

[0100] (2) Build the inner cabin of the experiment, its specification is: 800*600*600mm, the experiment cabin can effectively prevent fire and explosion and prevent damage from battery spray. Arrange the radiation hot runner to simulate the real external heat source, and control the temperature and temperature rise rate; fix the battery through a special clamping frame and facilitate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com