Driving device of UV lamp tube and driving method thereof

A driving device and lamp technology, applied in the direction of electrical components, etc., can solve problems such as difficult lamp frequency and lamp current control, increase product scrap rate and detection matching process test cycle, affect lamp brightness, etc., to prevent dimming or even failure in the later stage Brightness, avoid battery voltage drop, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

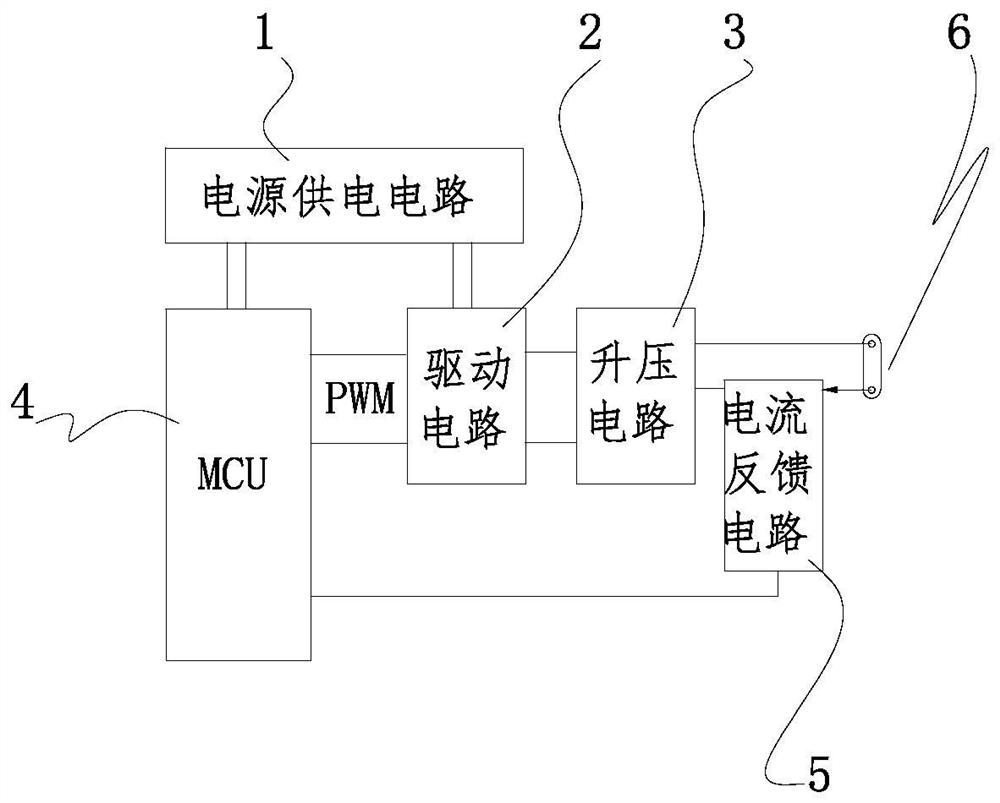

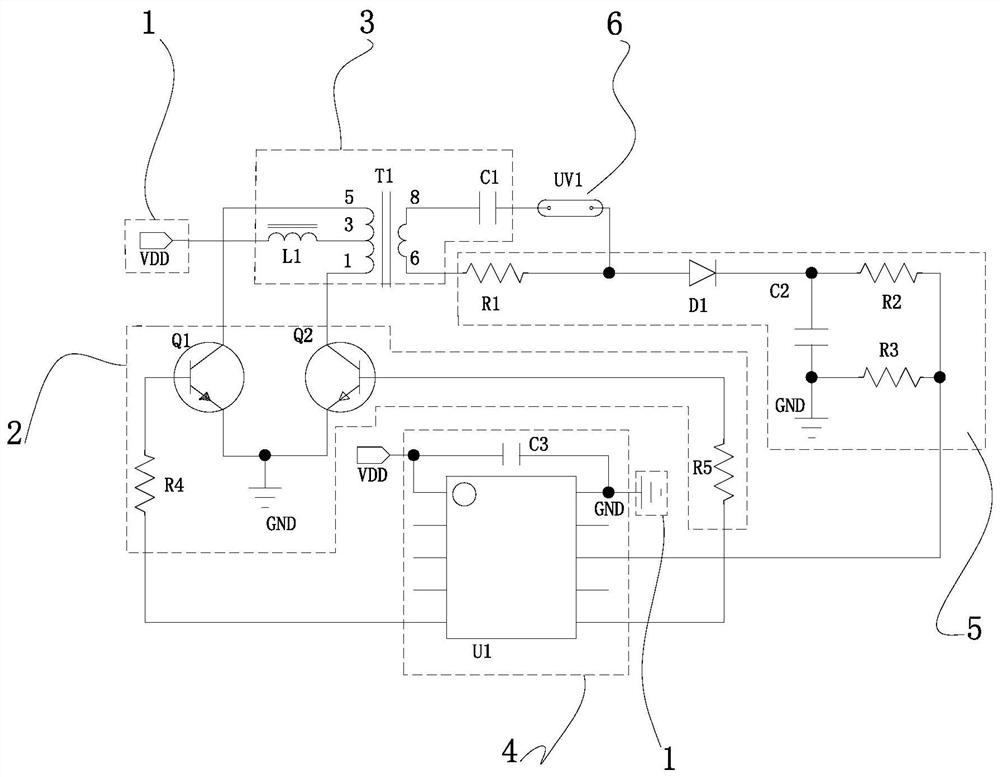

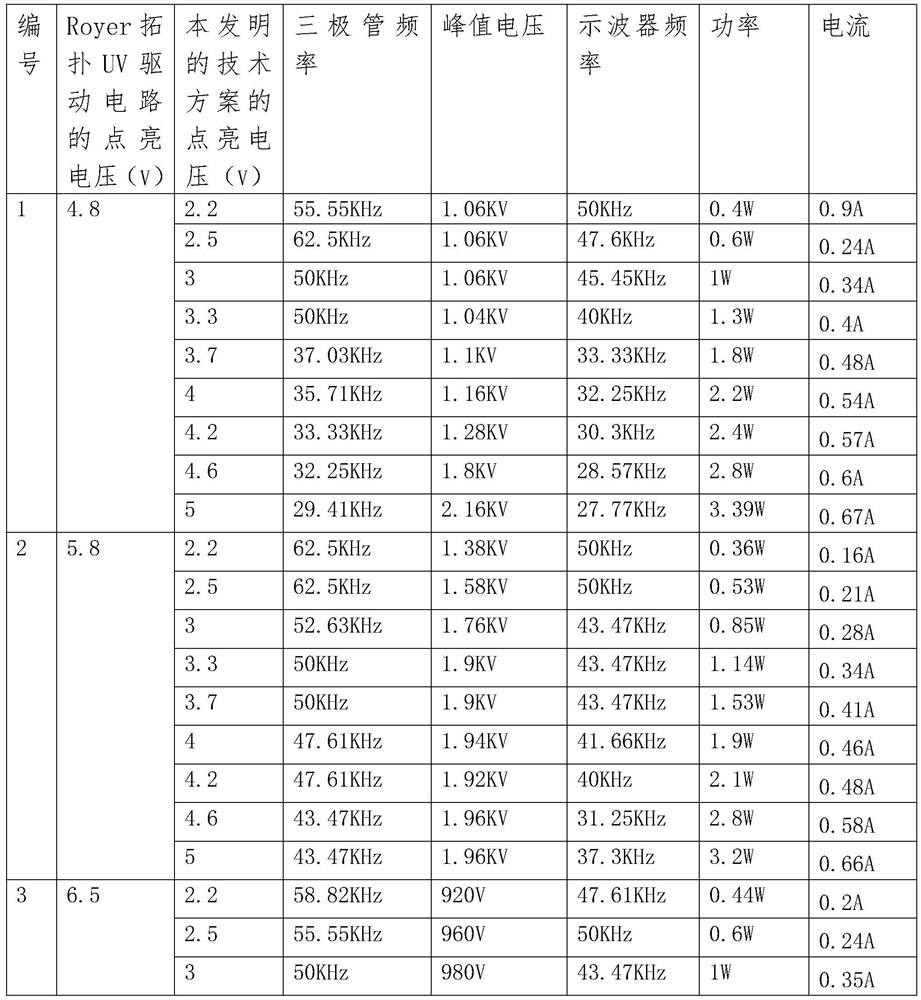

[0023] see Figure 1-Figure 2 , the driving device of the UV lamp includes a power supply circuit 1, a drive circuit 2, a boost circuit 3 and a UV lamp 6, and also includes a current feedback circuit 5 and an MCU single-chip microcomputer 4, wherein the power supply circuit 1 is connected to the MCU main The control circuit 4 is electrically connected with the drive circuit 2, and the MCU single-chip microcomputer 4, the drive circuit 2, and the booster circuit 3 are electrically connected in turn and connected with one end of the UV lamp 6, and the other end of the UV lamp 6 is connected to the booster through the current feedback circuit 5. The piezoelectric circuit 3 is electrically connected.

[0024] In this embodiment, the power supply circuit 1 is a battery-powered power supply circuit.

[0025] The battery is a primary battery or a secondary b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com