Pig bone concentrated soup stock and preparation method thereof

A technology for concentrating broth and pork bones, which is applied in the field of food seasonings, can solve the problems of inconvenient production and long production time, and achieve the effects of simple preparation, improved milky sensory feeling and rich flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

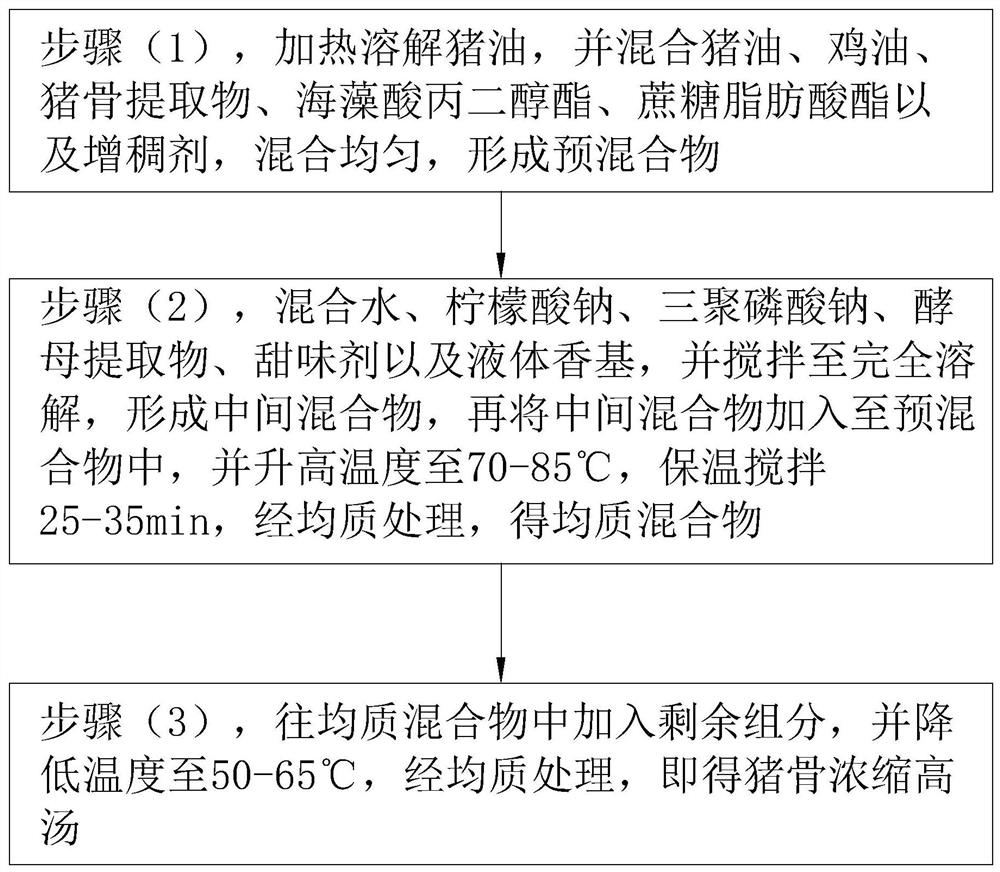

[0076] refer to figure 1 , the preparation method of pork bone concentrated broth comprises the following steps:

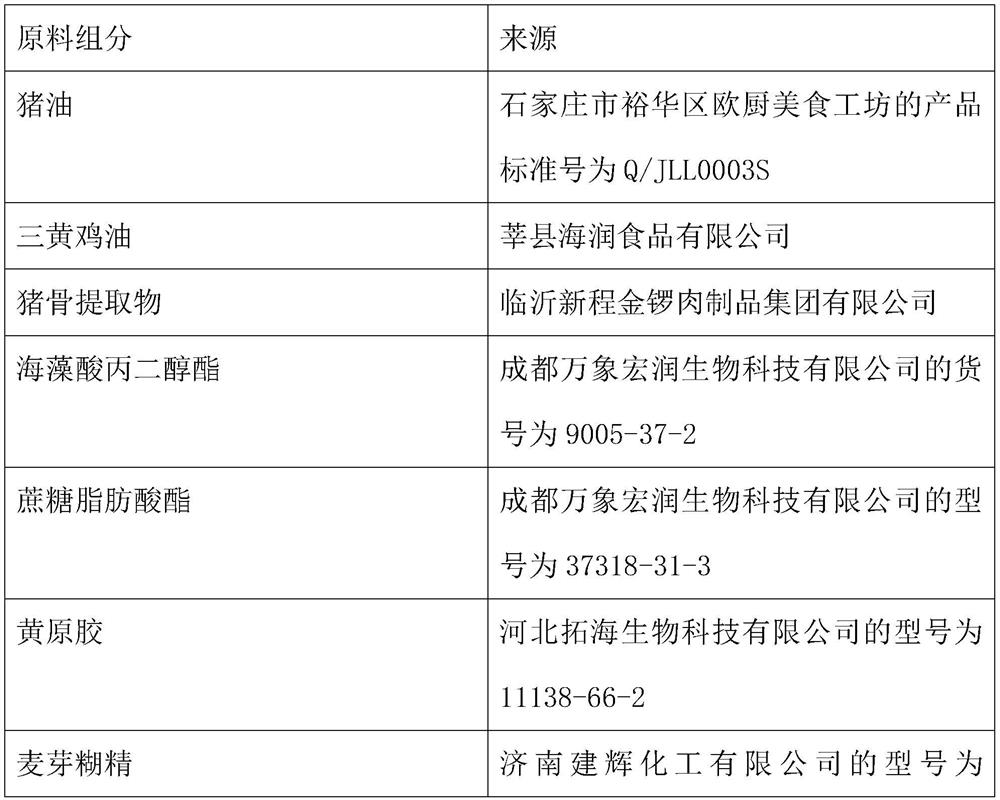

[0077] Step (1), add lard to the reaction kettle and heat it to 40°C to dissolve the lard, then add chicken oil, pig bone extract, propylene glycol alginate, and sucrose fatty acid ester to the dissolved lard and the thickener, and stir to combine to form a premix.

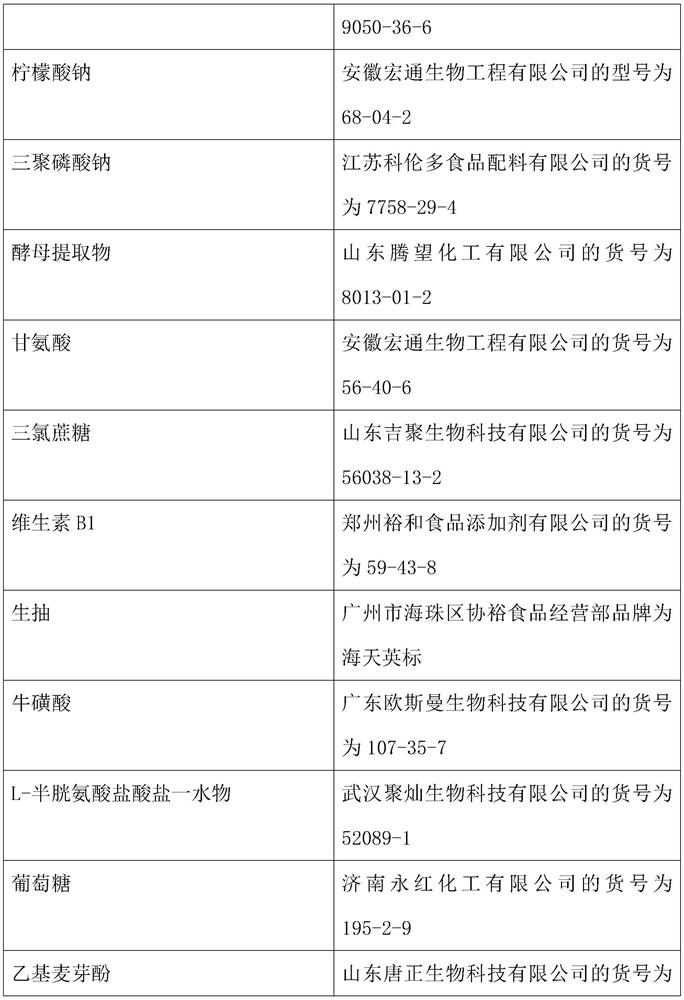

[0078] Step (2), add vitamin B1, light soy sauce, taurine, L-cysteine hydrochloride monohydrate, glucose and ethyl maltol into the second reaction kettle, raise the temperature to 95°C, and keep warm 3h, that is, the liquid fragrance base.

[0079] Add water, sodium citrate, sodium tripolyphosphate, yeast extract, sweetener and the liquid fragrance base prepared above into the third reaction kettle, and stir until completely dissolved to form an intermediate mixture, and then add the intermediate mixture to In the pre-mixture, raise the temperature to 70°C, keep it warm for 35min, and perform hom...

Embodiment 2

[0084] The difference with embodiment 1 is:

[0085] When preparing the liquid fragrance base in step (2), after mixing the raw material components of the liquid fragrance base, raise the temperature to 98°C and keep it warm for 2.7h; High temperature to 77.5 ℃, and keep warm for 30 minutes;

[0086] In step (3), reduce the temperature to 57.5°C.

[0087] Among them, the raw material components and contents of the liquid fragrance base are shown in Table 1; the raw material components and contents of the pork bone concentrated broth are shown in Table 2.

Embodiment 3

[0089] The difference with embodiment 1 is:

[0090] When preparing the liquid fragrance base in step (2), after mixing the raw material components of the liquid fragrance base, raise the temperature to 100° C. and keep it warm for 2.5 hours; High temperature to 85 ℃, and keep warm for 25 minutes;

[0091] In step (3), reduce the temperature to 65°C.

[0092] Among them, the raw material components and contents of the liquid fragrance base are shown in Table 1; the raw material components and contents of the pork bone concentrated broth are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com