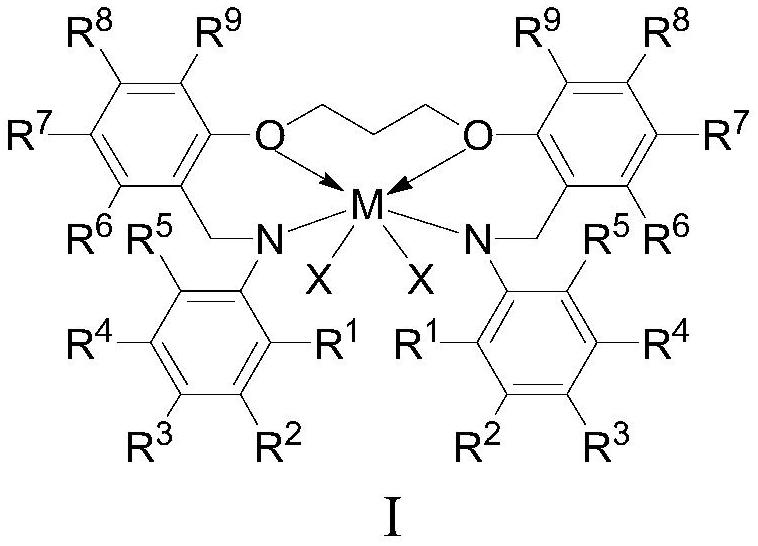

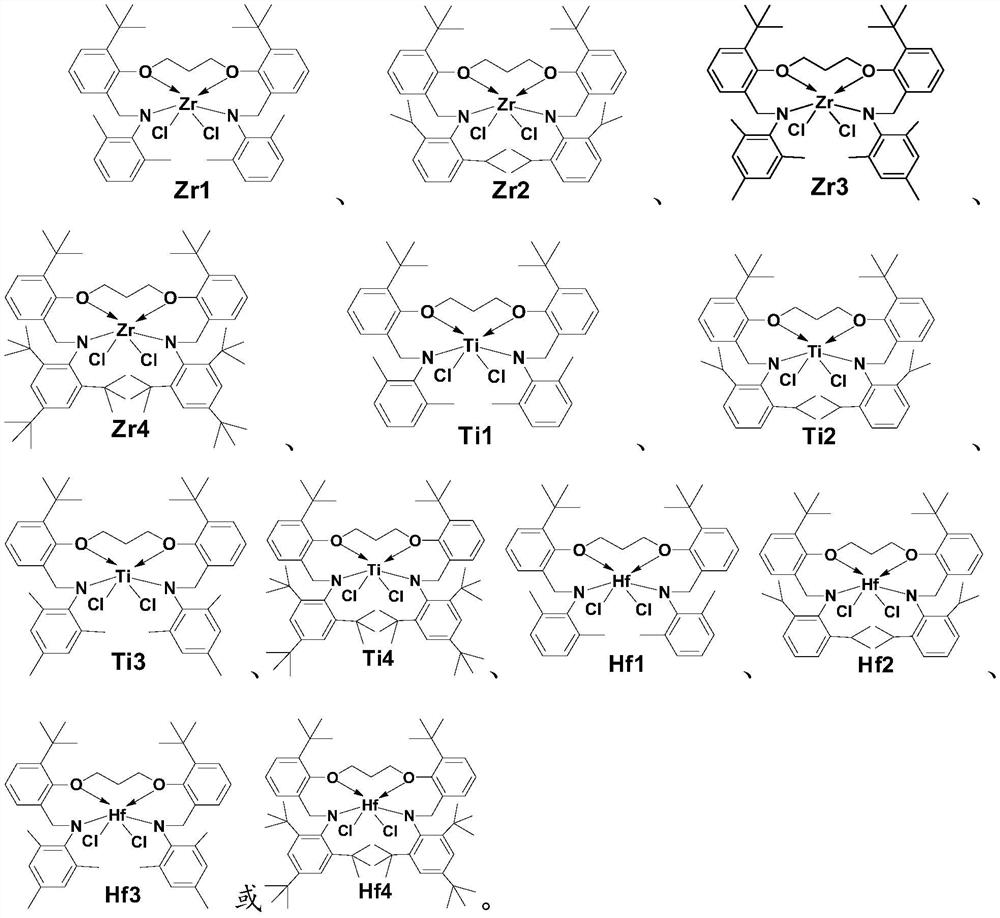

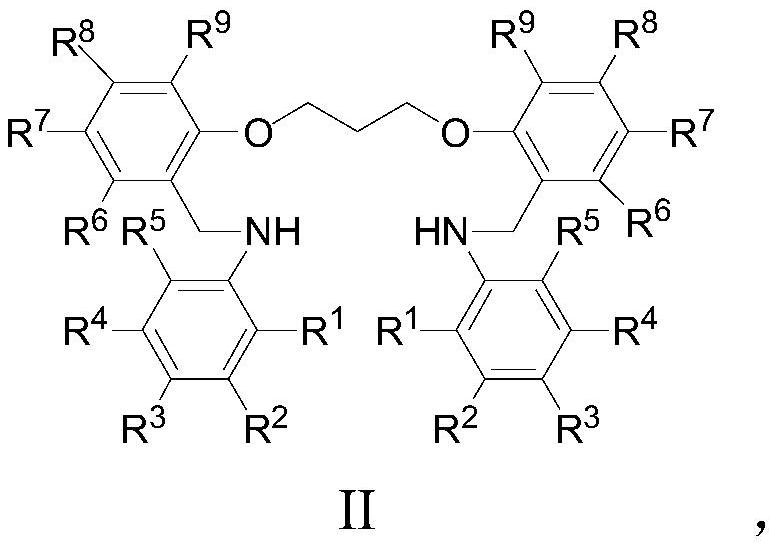

Arylamino ether metal complex as well as preparation method and application thereof

A technology of metal complexes and arylamino ethers, which is applied in the application field of ethylene homopolymerization or ethylene and α-olefin copolymerization, can solve the problems of high cost and complex synthesis route, and achieves high α-olefin insertion rate, high The effect of catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] Compound shown in the preparation formula A1 (R 1 = R 5 = Me; R 2 = R 3 = R 4 =H)

[0095] 3-tert-butyl salicylaldehyde (3.56g, 20mmol) and 2,6-dimethylaniline (2.43g, 20mmol) were added to a 100mL round-bottomed flask, respectively, and 50mL of anhydrous methanol and 0.10mL of formic acid were added, Heated to reflux for 6 hours, concentrated the reaction solution, and subjected to basic alumina column chromatography (petroleum ether: ethyl acetate = 50:1 (v / v)) to obtain 4.82 g of the product with a yield of 85.6%. 1 H NMR (CDCl 3 ,400MHz,TMS):δ8.78(s,1H,-CH=N-),7.35(d,J=8.0Hz,1H),7.16–7.14(m,4H),6.88(t,J=8.0Hz ,1H),5.74(s,1H,-OH),2.25(s,6H),1.40(s,9H). 13 C NMR (CDCl 3 ,100MHz,TMS):δ159.0,155.8,152.2,137.1,129.9,129.1,128.0,127.3,126.0,120.0,117.1,34.1,31.6,18.6.Anal.Calcd for C 19 h 23 NO (281.40): C, 81.10; H, 8.24; N, 4.98. Found: C, 80.83; H, 8.61; N, 4.74.

Embodiment 2

[0097] Compound shown in preparation formula A2 (R 1 = R 5 = i Pr; R 2=R 3 =R 4 =H)

[0098] The experimental procedure is the same as in Example 1. 3-tert-butyl salicylaldehyde (3.56g, 20mmol) was reacted with 2,6-diisopropylaniline (3.55g, 20mmol) to obtain 5.66g of product with a yield of 83.8%. 1 H NMR (CDCl 3 ,400MHz,TMS):δ8.78(s,1H,-CH=N-),7.38–7.35(m,2H),7.15–7.12(m,3H),6.88(t,J=8.0Hz,1H) ,5.74(s,1H,-OH),2.78–2.75(m,2H),1.40(s,9H),1.18(d,J=8.0Hz,12H). 13 C NMR (CDCl 3 ,100MHz,TMS):δ159.0,155.8,146.4,137.1,135.7,129.9,128.0,122.3,121.3,120.0,117.1,34.1,31.6,28.9,23.3.Anal.Calcd for C 23 h 31 NO (337.51): C, 81.85; H, 9.26; N, 4.15. Found: C, 81.53; H, 9.55; N, 4.01.

Embodiment 3

[0100] Compound shown in preparation formula A3 (R 1 =R 3 =R 5 = Me; R 2 =R 4 =H)

[0101] The experimental procedure is the same as that in Example 1, 3-tert-butyl salicylaldehyde (3.56g, 20mmol) reacted with 2,4,6-trimethylaniline (2.71g, 20mmol) to obtain 4.85g of product with a yield of 82.1% . 1 H NMR (CDCl 3 ,400MHz,TMS):δ8.78(s,1H,-CH=N-),7.35(d,J=8.0Hz,1H),7.15(d,J=8.0Hz,1H),6.98–6.96(m ,3H),5.74(s,1H,-OH),2.34(s,6H),2.18(s,3H),1.40(s,9H). 13 C NMR (CDCl 3 ,100MHz,TMS):δ159.0,155.8,149.2,137.1,129.9,128.2,128.0,125.4,120.0,117.1,34.1,31.6,21.9,18.9.Anal.Calcd for C 20 h 25 NO (295.43): C, 81.31; H, 8.53; N, 4.74. Found: C, 81.00; H, 8.82; N, 4.51.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com