Acid electrogalvanizing method of neodymium-iron-boron magnet

A technology of neodymium-iron-boron electroplating and galvanizing, applied in liquid cleaning methods, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of non-electroplating, low current efficiency of alkaline galvanizing, etc., and achieve strong conductivity , Improve the efficiency of electroplating, the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

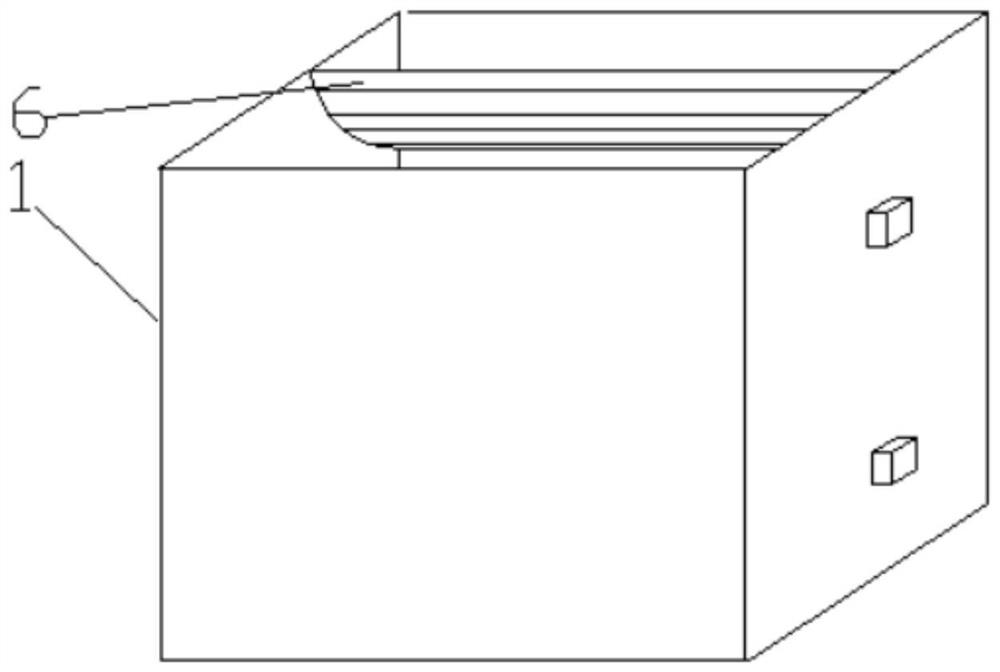

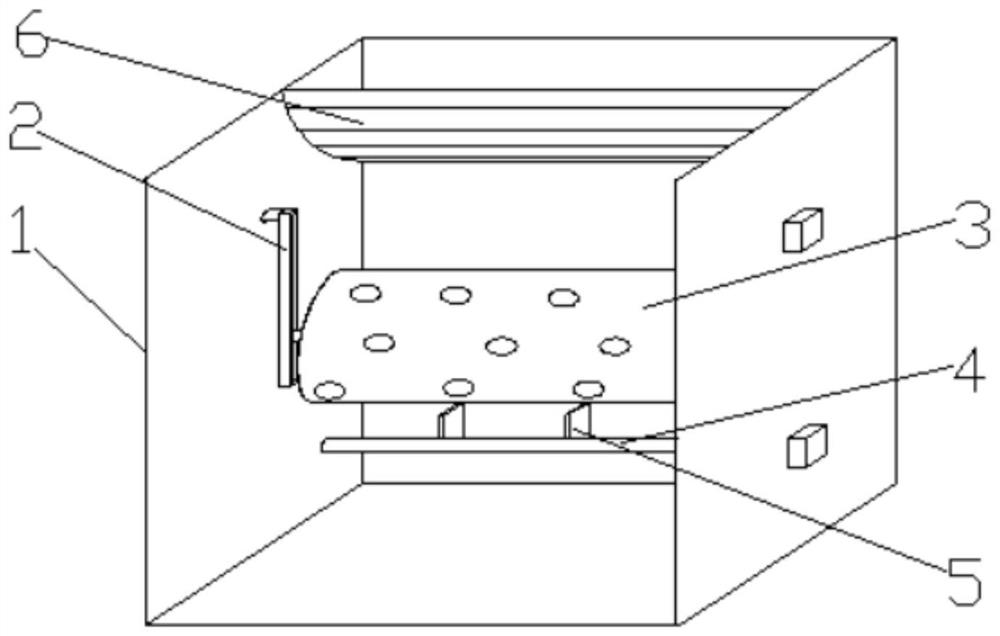

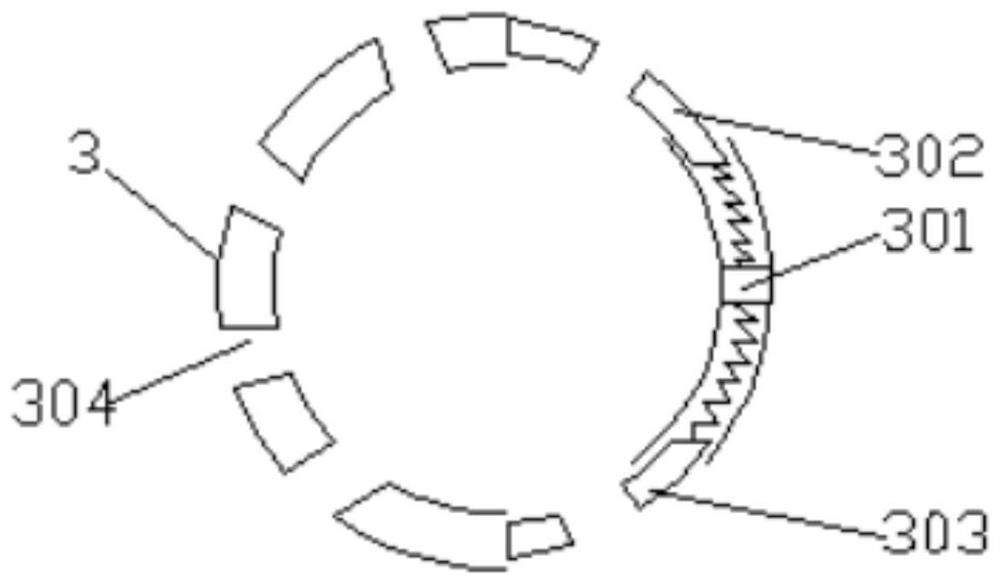

[0039] The invention provides a method for acid electrogalvanizing of neodymium-iron-boron magnets, which is characterized in that it comprises the following steps:

[0040] S1, using silicon carbide abrasives to remove the burrs on the surface of the NdFeB magnet raw material, and grinding the right angle at the corner of the NdFeB magnet raw material into an R angle to obtain an abrasive;

[0041] S2. Put the grinding material in a water-based metal cleaning agent solution with a mass fraction of 2%, and place it in a 20KHz ultrasonic wave at 40°C for 90s to obtain the first cleaning material, and then put the first cleaning material Placed in HNO with a mass fraction of 3% 3 solution at 10°C for 90s to obtain the second cleaning material, and then place the second cleaning material at 10°C in 20kHz ultrasonic treatment for 30s to obtain the preparatory material, wherein 1L of the metal cleaning agent includes chlorine Sodium chloride 150g, tartaric acid 2g, sodium lauryl s...

Embodiment 2

[0046] The invention provides a method for acid electrogalvanizing of neodymium-iron-boron magnets, which is characterized in that it comprises the following steps:

[0047] S1, using silicon carbide abrasives to remove the burrs on the surface of the NdFeB magnet raw material, and grinding the right angle at the corner of the NdFeB magnet raw material into an R angle to obtain an abrasive;

[0048] S2. Put the grinding material in a water-based metal cleaning agent solution with a mass fraction of 6%, and place it in an 80KHz ultrasonic wave at 60°C for 150s to obtain the first cleaning material, and then put the first cleaning material Placed in HNO with a mass fraction of 10% 3 solution at 35°C for 120s to obtain the second cleaning material, and then place the second cleaning material at 60°C in 80kHz ultrasonic wave for 90s to obtain the preparatory material, wherein 1L of the metal cleaning agent includes chlorine Sodium chloride 200g, tartaric acid 5g, sodium lauryl su...

Embodiment 3

[0053] The invention provides a method for acid electrogalvanizing of neodymium-iron-boron magnets, which is characterized in that it comprises the following steps:

[0054] S1, using silicon carbide abrasives to remove the burrs on the surface of the NdFeB magnet raw material, and grinding the right angle at the corner of the NdFeB magnet raw material into an R angle to obtain an abrasive;

[0055] S2. Put the grinding material in a water-based metal cleaning agent solution with a mass fraction of 4%, and place it in a 50KHz ultrasonic wave at 50°C for 120s to obtain the first cleaning material, and then put the first cleaning material Placed in HNO with a mass fraction of 6% 3 solution, treated at 20°C for 105s to obtain the second cleaning material, and then placed the second cleaning material in 50kHz ultrasonic wave at 35°C for 60s to obtain the preparatory material, wherein 1L of the metal cleaning agent included chlorine Sodium chloride 175g, tartaric acid 4g, sodium l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com