Layered polymer injection distributor, polymer intelligent layered injection system and application

A technology of injectors and polymers, which is applied in wellbore/well components, production fluid, earthwork drilling and production, etc., can solve the problems of inability to ensure long-term injection pass rate, low test efficiency, large choke core formation, etc. Achieve the effect of realizing unmanned operation at the wellhead, ensuring the qualified rate of dispensing, and reducing viscosity loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

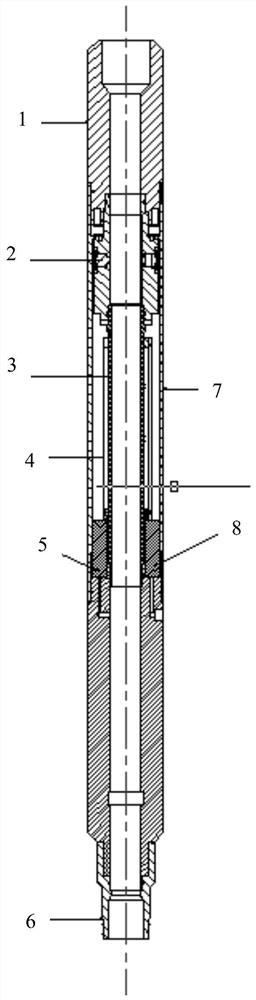

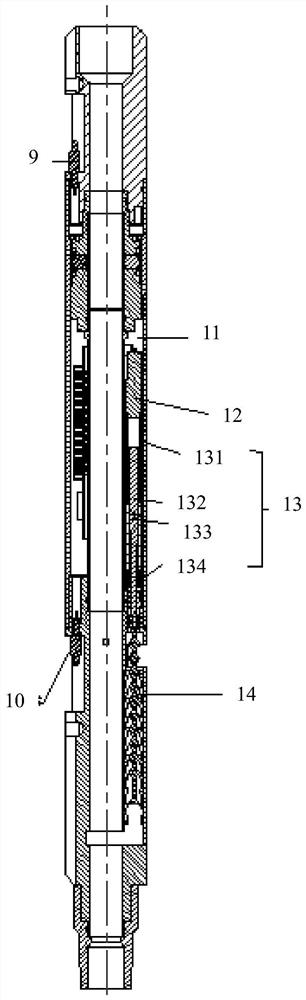

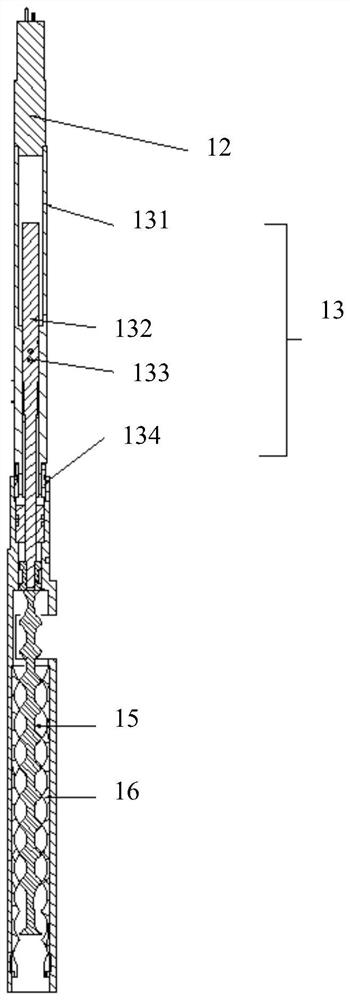

[0094] This embodiment provides a dispenser for layered polymer injection, wherein the front sectional view and left view sectional view of the dispenser for layered polymer injection are as follows Figure 1-Figure 2 As shown, it can be seen from the figure that the dispenser for layered polymer injection specifically includes:

[0095] Center pipe 3, external pressure cylinder 7, auxiliary cylinder 4, electromagnetic flowmeter 2, oil pipe pressure gauge 5, oil jacket annular pressure gauge 8, motor drive control circuit, signal processing control circuit, motor, transmission assembly and flow regulating valve ;

[0096] The top end and the bottom end of the external pressure cylinder are threadedly connected with the upper joint 1 of the dispenser and the lower joint 6 of the dispenser respectively;

[0097] The electromagnetic flowmeter is fixed on the inner step of the outer pressure cylinder by the pressing force of the joint on the dispenser;

[0098] The center pipe i...

Embodiment 2

[0118] This embodiment provides a polymer intelligent dispensing system, wherein, the structure diagram of the polymer intelligent dispensing system is as follows Figure 7 shown, from Figure 7 It can be seen from the figure that the polymer intelligent dispensing system includes:

[0119] Polymer intelligent split injection pipe string (pipe string of two-layer split injection well) and ground control box;

[0120] The polymer intelligent distribution string includes tubing 17, two packers and two injectors for layered polymer injection provided in Embodiment 1, two packers and two layered polymer injection Distributors are arranged alternately on the tubing, that is, from top to bottom, and the order of installation is: first packer 19, first distributor for layered polymer injection 20, second packer 21 and second distributor. The injector 22 for layer injection;

[0121] The two packers and the two dispensers for layered polymer injection are connected to the ground co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com